A kind of highly transparent polyester film and preparation method thereof

A polyester film and transparent technology, applied in the field of organic polymer compounds and their preparation, can solve the problems of low haze, high light transmittance and reduced transparency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~10

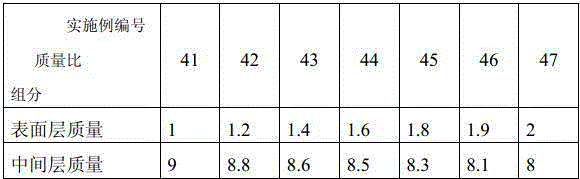

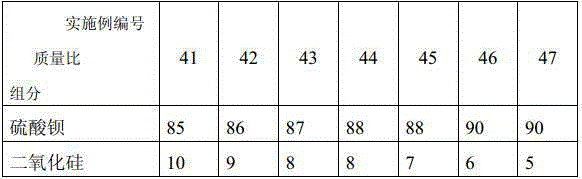

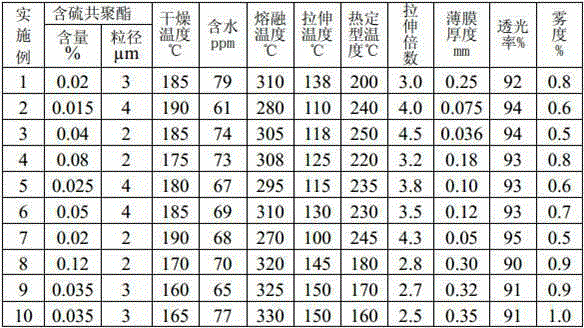

[0049] The basic technological parameter and process of embodiment 1~10:

[0050] Copolyester slices containing 0.015% to 0.12% by mass ratio of 2 to 4 micron surface-treated barium sulfate (referred to as "sulfur-containing copolyester" in Table 1 below) chips were dried at 160 to 190°C until the moisture content was lower than At 80ppm, add it into the extruder, melt and extrude at 270-330°C and filter through a fine filter with a pore size of 25μm, extrude from the single-layer head of the extruder, cool and cast on a cold drum at 15-25°C The sheet is stretched 2.5 to 4.5 times in the longitudinal and transverse directions simultaneously at 100 to 150°C, then heat-set at 160 to 250°C, and then wound and cut to obtain a single-layer structure highly transparent polyester film product . in:

Embodiment 1

[0051] The copolyester containing 0.02% of 3 micron-order surface-treated barium sulfate in Example 1 is a copolyester formed by copolymerization of 1,4-cyclohexanedimethanol, ethylene glycol, isophthalic acid, and terephthalic acid. A mixture of polyester and surface-treated barium sulfate, in which 1,4-cyclohexanedimethanol accounts for 5% by mole of diol, isophthalic acid accounts for 3% by mole of dibasic acid, and has a viscosity of 0.80dL / g.

Embodiment 2

[0052] The copolyester containing 0.015% of 4 micron-order surface-treated barium sulfate in embodiment 2 is formed by the copolymerization of 1,4-cyclohexanedimethanol, ethylene glycol, terephthalic acid, and 2,6-naphthalene dicarboxylic acid. The copolyester formed, in which 1,4-cyclohexanedimethanol accounted for 12% of the molar content of the dibasic alcohol, 2,6-naphthalene dicarboxylic acid accounted for 1% of the molar content of the dibasic acid, and the viscosity was 0.64dL / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com