Sulfonated polystyrene flame retardant and low-halogen flame-retardant polypropylene material

A technology of sulfonated polystyrene and flame-retardant polypropylene, which is applied in the field of sulfonated polystyrene flame retardants and low-halogen flame-retardant polypropylene materials, can solve poor compatibility, limit application fields, and lose the transparency of PP resin And other problems, to achieve good flame retardant effect, the effect of permeability is not affected

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Add polystyrene and oleum with a molar ratio of 1:1 into a three-necked flask protected by nitrogen, wherein the melt index of polystyrene is 20g / 10min, and the mass fraction of sulfur trioxide in oleum is 40% , control the reaction temperature at 60°C, and the reaction time is 6 hours. After the reaction, the reaction system is cooled to room temperature, and sodium chloride with the same molar amount as polystyrene is added to the reaction vessel to salt out the sulfonated product. , neutralized with sodium hydroxide to a pH value of 7-8, filtered, dried, and extracted and purified with toluene to obtain a sulfonated polystyrene flame retardant.

Embodiment 2

[0030] Be that polystyrene and the concentrated sulfuric acid that molar ratio is 1: 1.02 join in the there-necked flask that has nitrogen protection, wherein the melt index of polystyrene is 25g / 10min, H2SO4 mass fraction is 98% in the concentrated sulfuric acid, control reaction temperature At 60°C, the reaction time is 5 hours. After the reaction, the reaction system is cooled to room temperature, and potassium chloride with the same molar amount as polystyrene is added to the reaction vessel to salt out the sulfonated product and oxidized with hydrogen. Potassium is neutralized to a pH value of 7-8, filtered, dried, and then extracted and purified with toluene to obtain a sulfonated polystyrene flame retardant.

Embodiment 3

[0032] Be that polystyrene and chlorosulfonic acid that molar ratio is 1: 1.05 join in the there-necked flask that has nitrogen protection, wherein the melt index of polystyrene is 30g / 10min, the mass fraction of chlorosulfonic acid is 97%, control reaction temperature At 50°C, the reaction time is 5 hours. After the reaction, the reaction system is cooled to room temperature, and sodium chloride with the same molar amount as polystyrene is added to the reaction vessel to salt out the sulfonated product and oxidized with hydrogen. Sodium is neutralized to a pH value of 7-8, filtered, dried, and then extracted and purified with toluene to obtain a sulfonated polystyrene flame retardant.

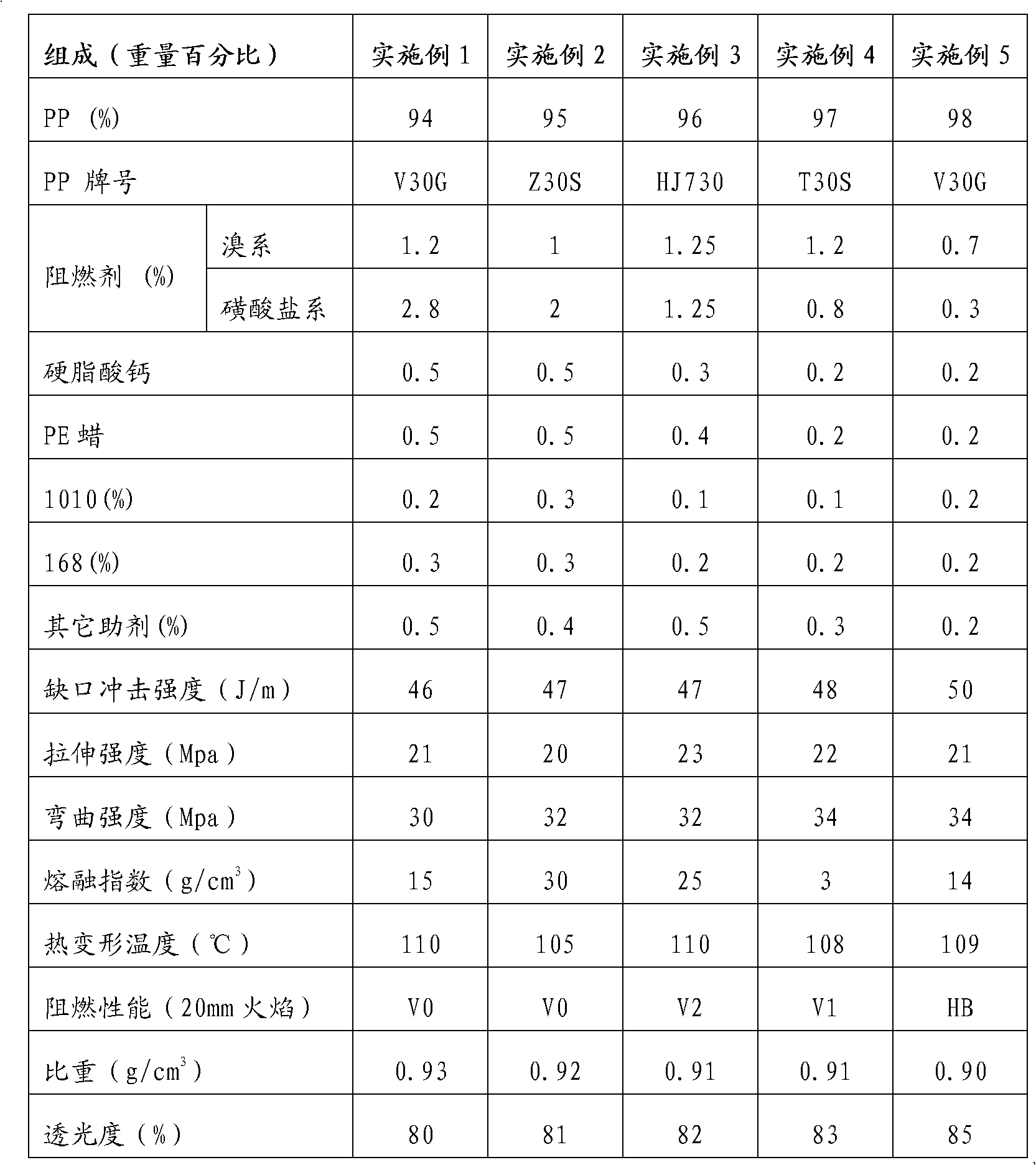

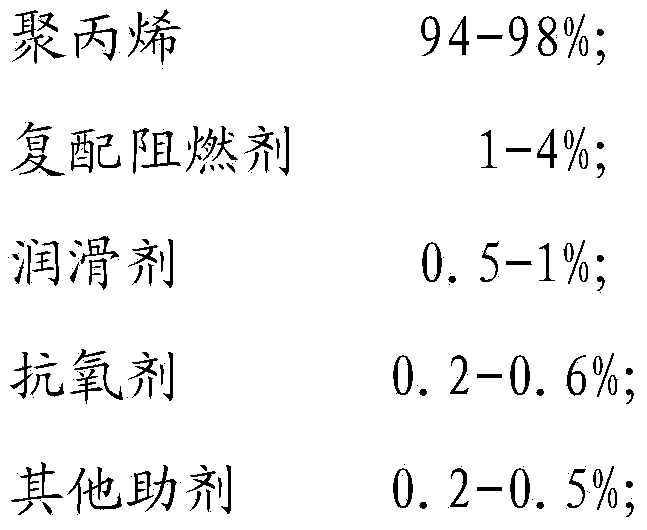

[0033] The composition of the low-halogen flame-retardant polypropylene material of the present invention is (%) by weight percentage: polypropylene PP 94-98%; compound flame retardant 1-4%; lubricant 0.5-1%; antioxidant 0.2-0.6% %. Other additives 0.2-0.5%.

[0034] Among them, PP is a homo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com