A Coal Seam Water Injection Method Enhanced by Pressure Dynamic-Electric Coupling

A coal seam water injection and action technology, applied in the direction of wellbore/well components, mining fluid, earth cube drilling and mining, etc., can solve the problem of insufficient wetting of coal body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

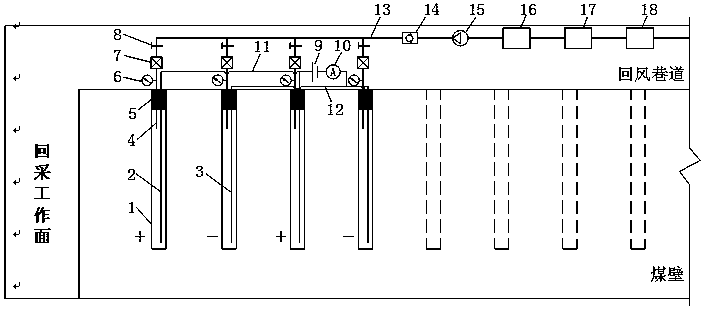

[0025] Implementation of a method for enhanced coal seam water injection through pressure-electric coupling, the method is carried out in the following steps:

[0026] Step 1. The length of the working face of a mine is 150m, the thickness of the coal seam is 3.2m, and the type of coal mined is anthracite. The coal seam of a mine is drilled and sampled, and the uniaxial compressive strength of the coal sample is 7.36MPa, and the porosity is 3.82%. , water content 1.18%, water permeability coefficient 3.515×10 -4 cm 2 ·atm -1 ·s -1 , to determine the maximum water injection pressure 15MPa.

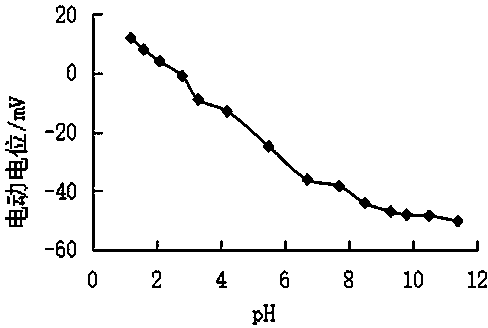

[0027] Step 2. Use the coal-rock electric-pneumatic triaxial seepage test device to measure the electric permeability coefficient of the coal sample to be 8.578×10 -4 cm 2 ·V -1 ·s -1 , using a micro-electrophoresis instrument to test the zeta potential of anthracite samples in aqueous solutions with different pH values, see attached image 3 , considering that the excessive pH of t...

Embodiment approach 2

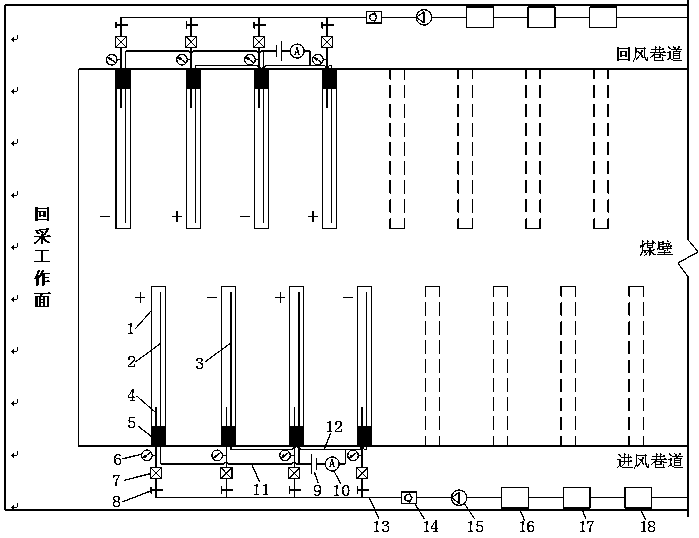

[0033] Step 1. The length of the working face of a certain second mine is 200m, the thickness of the coal seam is 2.8m, and the mined coal is coking coal; the coal seam of a certain second mine is drilled and sampled, and the uniaxial compressive strength of the coal sample is determined to be 5.92MPa, and the porosity is 2.35%. , water content 1.64%, water permeability coefficient 1.906×10 -4 cm 2 ·atm -1 ·s -1 , to determine the maximum water injection pressure 16MPa.

[0034] Step 2. The electric permeability coefficient of the coal sample is determined to be 11.493×10 by using the coal-rock electric-pneumatic triaxial seepage test device -4 cm 2 ·V -1 ·s -1 , using a micro-electrophoresis instrument to test the zeta potential of coal samples in aqueous solutions with different pH values, see attached Figure 4 , considering that the excessive acidity and alkalinity of the coal sample will cause equipment corrosion, the pH of the injection solution is determined to b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com