Quality stability testing method for tipping paper for cigarettes

A technology of quality stability and cigarette tipping paper, which can be used in measuring devices, instruments, scientific instruments, etc., and can solve problems such as printing surface adhesion, hidden dangers of cigarette product quality, and adhesion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The invention is further described by the following examples (figures).

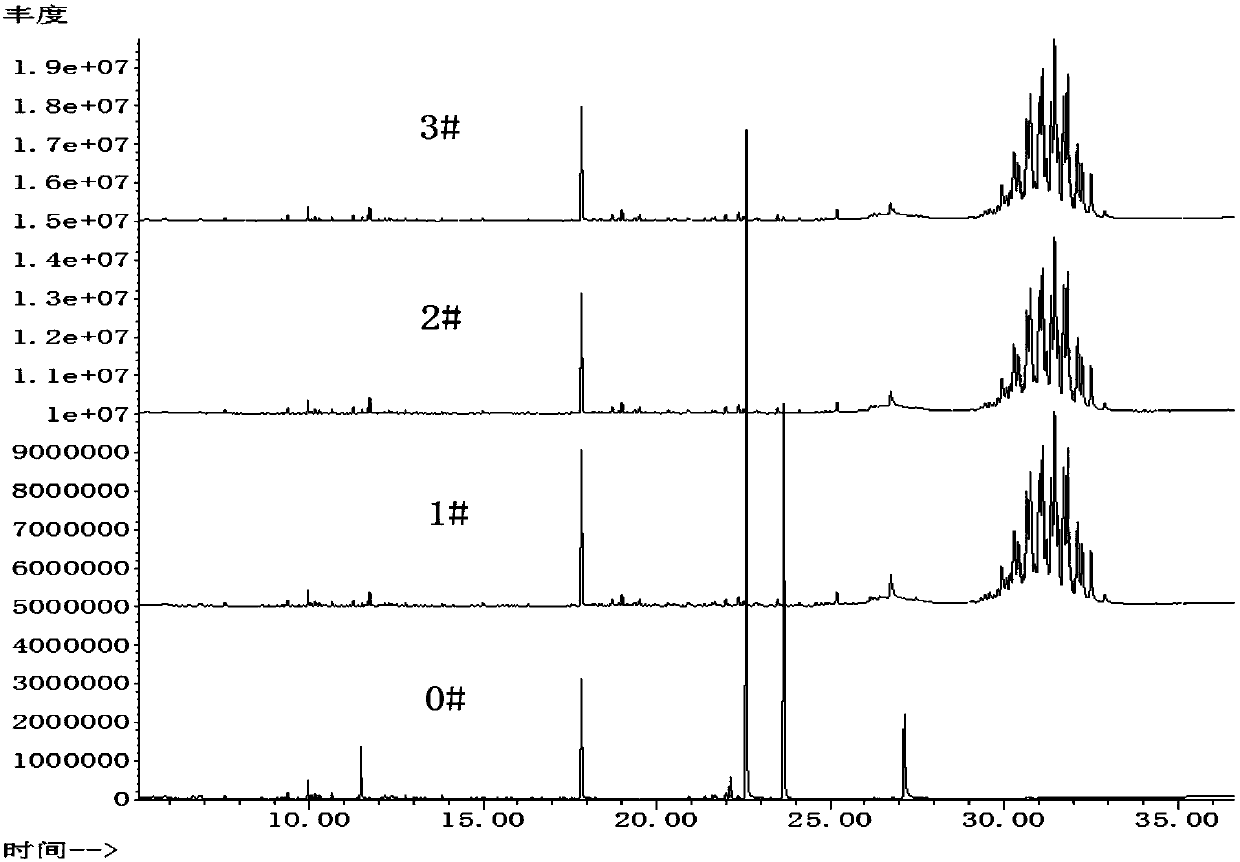

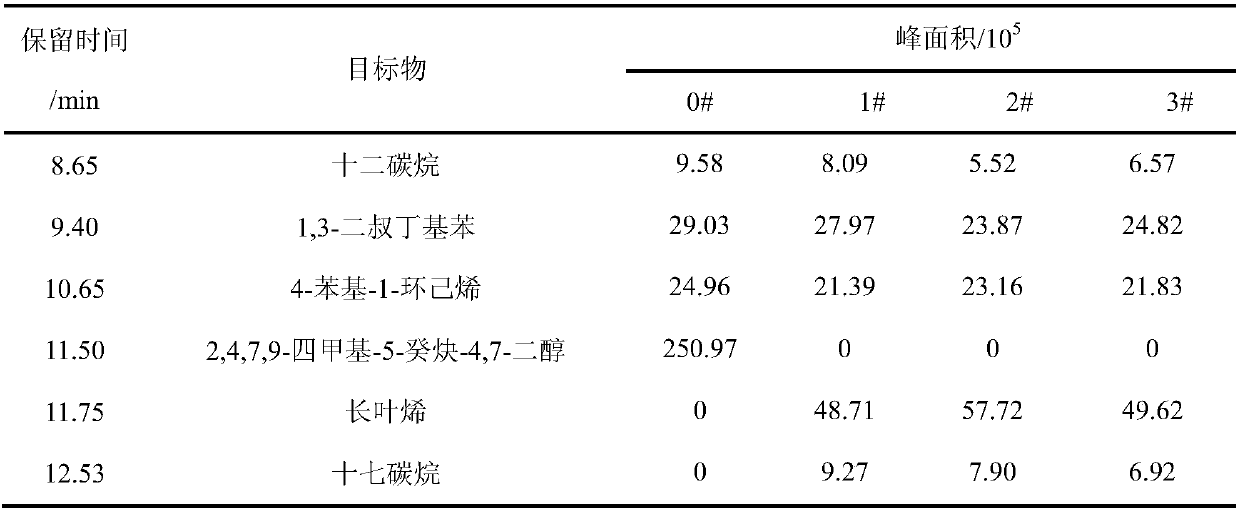

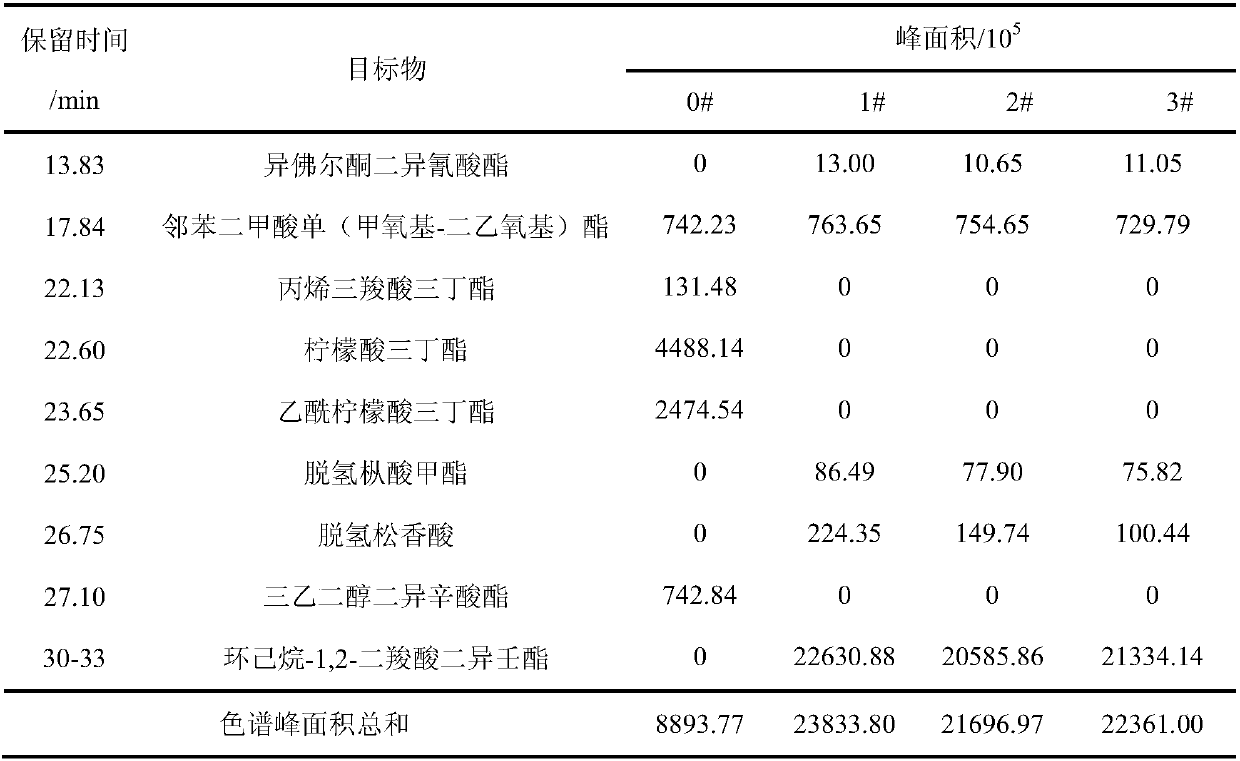

[0035] Take 4 trays of cigarette tipping papers of specification X produced by manufacturer A from the cigarette production workshop. The 4 trays of tipping papers belong to different batches, and one tray of tipping papers has different cigarettes during the cigarette production process. Surface sticking phenomenon, the number is 0#, and the numbers of the three normal tipping papers used in cigarettes are 1#, 2#, and 3# respectively. After removing about 15 layers on the surface of each tray, cut paper stacks with a length of 400 mm and a thickness of 30 mm, and put them into clean aluminum foil bags and seal them.

[0036] Take out the tipping paper samples in the aluminum foil bag, remove 10 layers on both sides, take 20 paper samples, and cut them into pieces with an area of about 1mm 2 small pieces of paper. The samples were placed in a constant temperature and humidity box for equilibri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com