Preparation method of palladium-mesoporous silicon oxide hollow multi-core nanometer catalytic material

A technology of nano-catalytic materials and mesoporous silicon oxide, which can be applied to electrical components, battery electrodes, circuits, etc., and can solve problems such as synergistic template method and preparation of materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] (1) Weigh 0.05g CTAB and 0.125g F127, add a mixture of 10mL deionized water and 4mL absolute ethanol, stir at 30°C for 30 minutes, add 0.05mL 0.5M sodium hydroxide NaOH aqueous solution and continue stirring for 15 minutes;

[0022] (2) Add 0.10g resorcinol, stir for 30 minutes, add 0.15mL formaldehyde solution, stir the mixture at 30°C for 24 hours, then add 0.50mL0.1M sodium chloropalladate Na 2 PdCl 4 aqueous solution, and the solution was transferred to a polytetrafluoroethylene-lined stainless steel reactor, and reacted at 100°C for 24 hours;

[0023] (3) Centrifuge the product, wash it with water and ethanol, dry it overnight in an oven at 60°C, and grind it finely with an agate mortar to obtain Pd@RF nanospheres;

[0024] (4) Weigh 0.075g CTAB, add a mixture of 25mL deionized water and 10mL absolute ethanol, stir at 30°C for 15 minutes, add 1mL ethanol solution containing 0.05g Pd@RF beads, and ultrasonicate for 15 minutes to make Pd @RF beads are evenly disper...

Embodiment 2

[0029] (1) Weigh 0.025g CTAB and 0.50g F127, add a mixture of 10mL deionized water and 6mL absolute ethanol, stir at 50°C for 30 minutes, add 0.30mL 25wt% ammonia water and continue stirring for 30 minutes;

[0030] (2) Add 0.15g resorcinol, stir for 30 minutes, add 0.20mL formaldehyde solution, stir the mixture at 30°C for 24 hours, then add 0.75mL 0.1M palladium chloride PdCl 2 aqueous solution, and the solution was transferred to a polytetrafluoroethylene-lined stainless steel reactor, and reacted at 100°C for 24 hours;

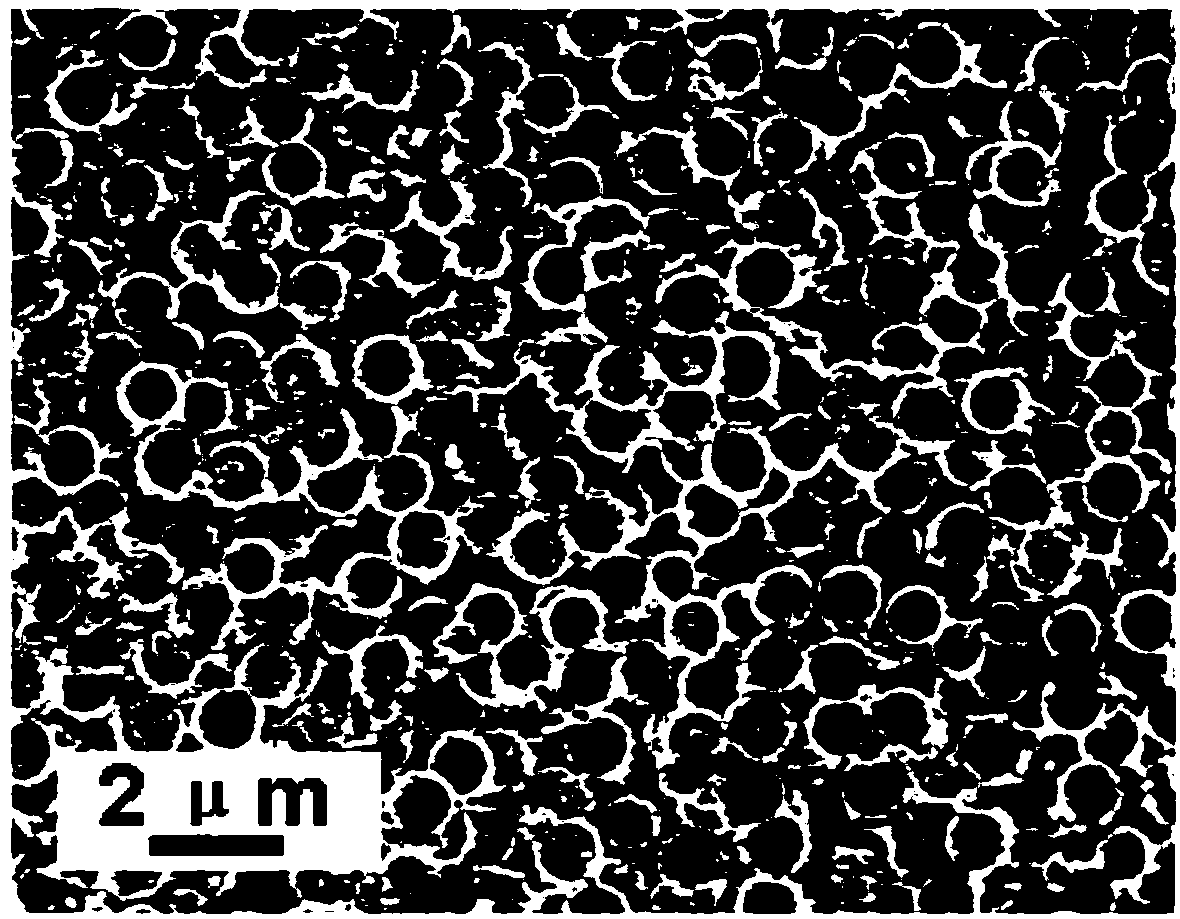

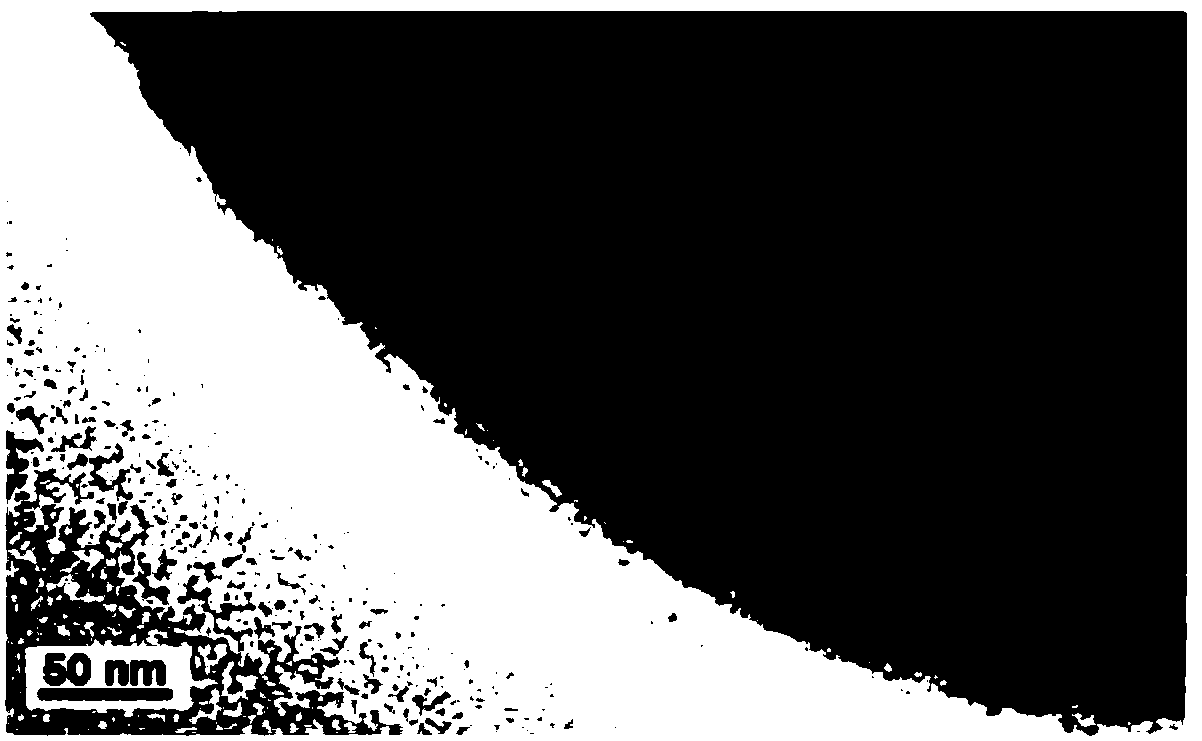

[0031] (3) The product was centrifuged, washed with water and ethanol, dried overnight in an oven at 60°C, and ground with an agate mortar to obtain Pd@RF nanospheres. figure 2 It is the transmission electron microscope TEM picture of this nanomaterial;

[0032] (4) Weigh 0.125g CTAB, add a mixture of 25mL deionized water and 20mL absolute ethanol, stir at 50°C for 15 minutes, add 1mL ethanol solution containing 0.075g Pd@RF beads, and ultrasonicate for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com