Refining method of tetrakis(dimethylamido)titanium

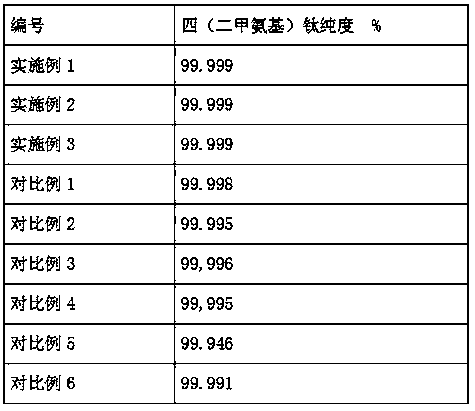

A technology of dimethylamino and refining methods, which is applied in the field of purification of amino titanium, can solve the problem that the purity of titanium is difficult to exceed 99.99%.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A method for refining tetrakis(dimethylamino)titanium, comprising the following steps:

[0020] (1) In parts by weight, 100 parts of polysulfone hollow fiber ultrafiltration membranes are immersed in 1500 parts of deionized water and 8 parts of 2-hydroxyl-4-trifluoromethylaniline mixed solution, soaked for 17 hours, and taken out Dry it in the air, then immerse it in 1800 parts of n-hexane, 19 parts of trimesoyl chloride, soak it for 15 hours, take it out, dry it at 60°C, then immerse it in 1500 parts of n-hexane, 0.005 part of 2,4-decadienal, In a mixed solution of 0.004 parts of dicyclopentadiene titanium dichloride and 0.08 parts of 3,3-diallyltetrahydrofuran-2-ol, N 2 For protection, 60Co γ-ray irradiation dose is about 30kGy, and the irradiation time is 19 minutes. The grafted membrane is taken out, and the surface of the membrane is cleaned with 1500 parts of methanol and dried to obtain tetrakis(dimethylamino)titanium purification permeation membrane.

[0021] (...

Embodiment 2

[0023] A method for refining tetrakis(dimethylamino)titanium, comprising the following steps:

[0024] (1) In parts by weight, 100 parts of polysulfone hollow fiber ultrafiltration membranes are immersed in 1000 parts of deionized water and 3 parts of 2-hydroxyl-4-trifluoromethylaniline mixed solution, soaked for 10 hours, and taken out Dry it in the air, then immerse it in 1000 parts of n-hexane, 10 parts of trimesoyl chloride, soak for 10 hours, take it out, dry it at 50°C, then immerse it in 1000 parts of n-hexane, 0.001 part of 2,4-decadienal, In a mixed solution of 0.001 part of dicyclopentadiene titanium dichloride and 0.01 part of 3,3-diallyltetrahydrofuran-2-ol, N 2 For protection, 60Co γ-ray irradiation dose is about 10kGy, and the irradiation time is 30 minutes. The grafted membrane is taken out, and the surface of the membrane is cleaned with 1000 parts of methanol, and dried to obtain tetrakis(dimethylamino)titanium purification permeation membrane.

[0025] (2) I...

Embodiment 3

[0027] A method for refining tetrakis(dimethylamino)titanium, comprising the following steps:

[0028] (1) In parts by weight, 100 parts of polysulfone hollow fiber ultrafiltration membranes are immersed in 2000 parts of deionized water and 10 parts of 2-hydroxyl-4-trifluoromethylaniline mixed solution, soaked for 30 hours, and taken out Dry it in the air, then immerse it in 2000 parts of n-hexane, 30 parts of trimesoyl chloride, soak it for 30 hours, take it out, dry it at 80°C, then immerse it in 2000 parts of n-hexane, 0.01 part of 2,4-decadienal, In a mixed solution of 0.01 part of dicyclopentadiene titanium dichloride and 0.1 part of 3,3-diallyltetrahydrofuran-2-ol, N 2 For protection, 60Co γ-ray irradiation dose is about 50kGy, and the irradiation time is 10 minutes. The grafted membrane is taken out, and the surface of the membrane is cleaned with 2000 parts of methanol, and dried to obtain tetrakis(dimethylamino)titanium purification permeation membrane.

[0029] (2) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com