Method for preparing Mo-doped VO2 thermochromic film through atomic layer deposition method

An atomic layer deposition method, VO2 technology, applied in the direction of coating, metal material coating process, gaseous chemical plating, etc., can solve the problems of limited practical application, high human hazard, high phase transition temperature, etc., and achieve excellent thermal induction Phase change characteristics, large-scale mass production, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] The precursor V(NMe 2 ) 4 and Mo(CO) 6 Heat to 50°C, and pulse alternately into the ALD reaction chamber, the chamber temperature is controlled at 160°C. The gas flow is set to 300sccm, and the reaction pressure is 0.5mbar, O 2 The plasma power was set to 80W. an ALD VO 2 The pulse purge program is V(NMe 2 ) 4 (3s)—Ar(8s)—H 2 O(0.6s)—Ar(3s), an ALD MoO 3 The pulse purge program for Mo(CO) 6 (1s)—Ar(4s)—O 2 (1s)—Ar(3s). Pass 2 ALD MoOs 3 Subloop and 98 ALD VO 2 The sub-loop is repeated 5 times alternately to obtain MoO 3 Cycle ratio of 2% VO 2 / MoO 3 Nano lamination. The nano-stack was incubated at 500°C in a vacuum (about 1 Pa) for 120 min to obtain crystallized V 1-x Mo x o 2 film.

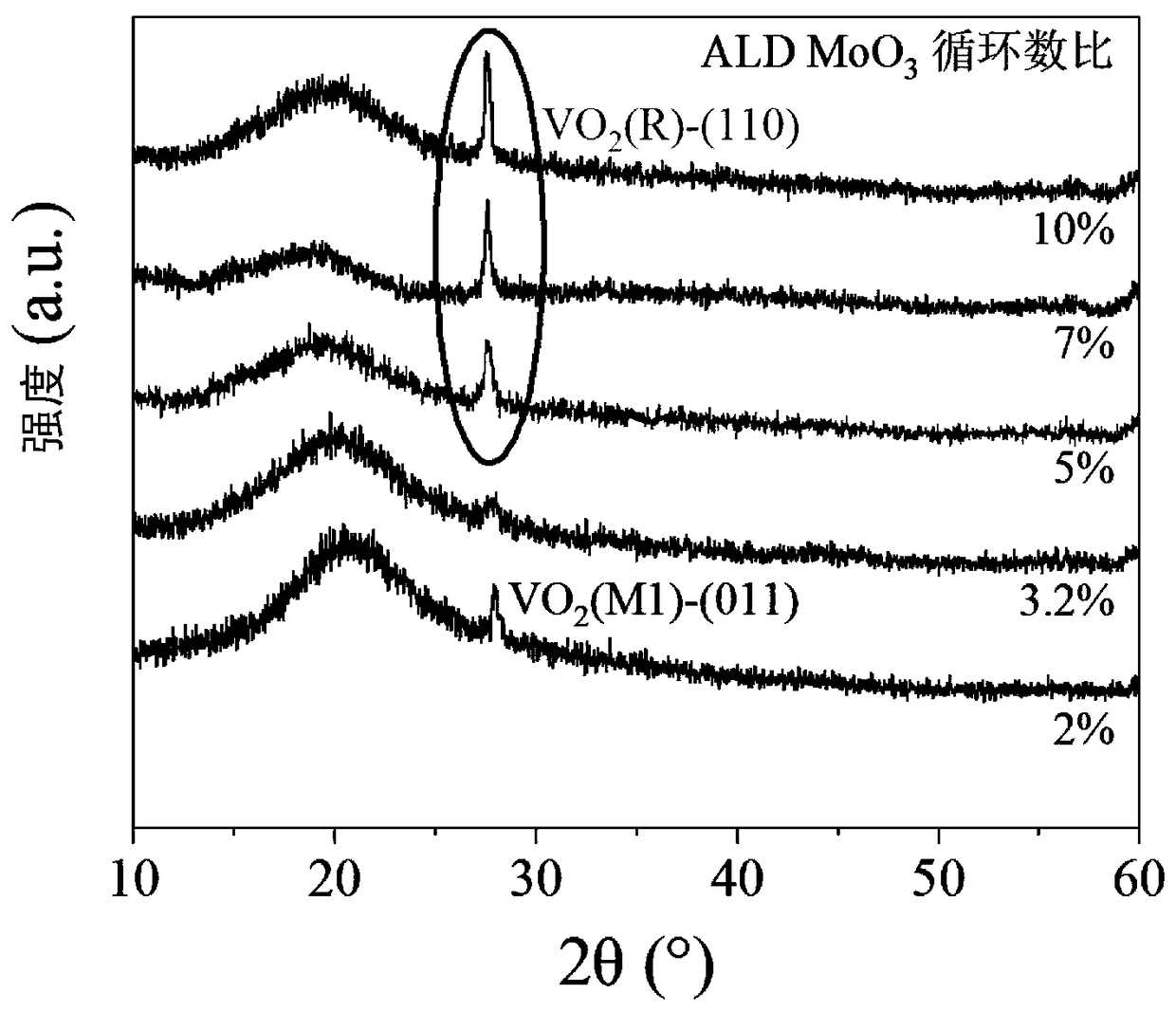

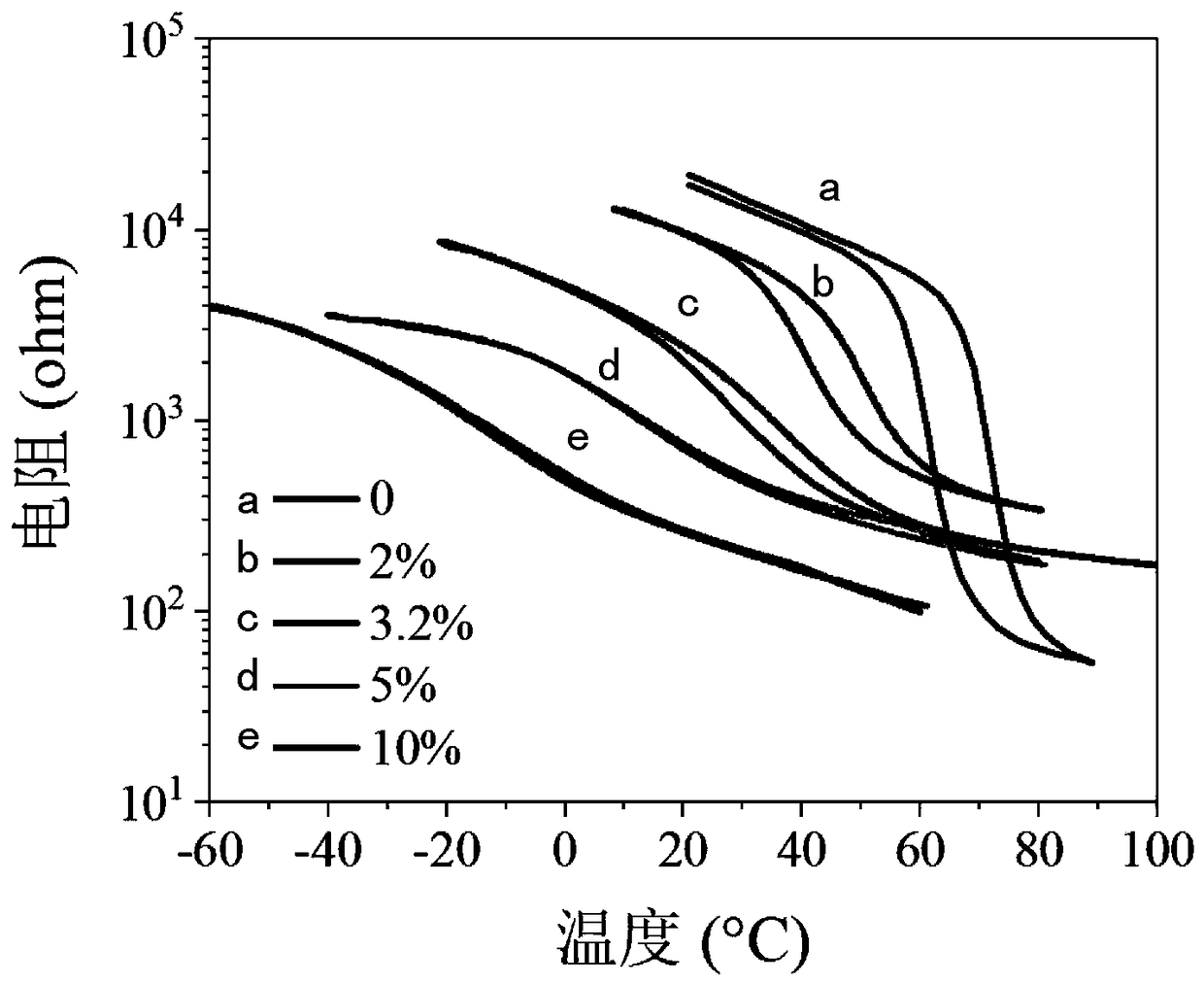

[0055] to get V 1-x Mo x o 2 The film was tested, and the phase composition of the film was checked by X-ray diffractometer ( figure 1 ); using a field emission scanning electron microscope to observe the morphology of the film ( figure 2 ); The variable temperatu...

Embodiment 2

[0057] The precursor V(NMe 2 ) 4 and Mo(CO) 6 Heat to 50°C, and pulse alternately into the ALD reaction chamber, the chamber temperature is controlled at 180°C. The gas flow is set to 300sccm, and the reaction pressure is 0.5mbar, O 2 The plasma power was set to 60W. an ALD VO 2 The pulse purge program for H 2 O(0.6s)—Ar(3s)—V(NMe 2 ) 4 (3s)—Ar(8s), an ALD MoO 3 The pulse purge program is O 2 (1s)—Ar(3s)—Mo(CO) 6 (1s)—Ar(4s). By combining 5 ALD MoO 3 Subcycle and 95 ALD VO 2 The sub-loop is repeated 5 times alternately to obtain MoO 3 Cycle ratio of 5% VO 2 / MoO 3 Nano lamination. The nanostack was incubated in vacuum at 500 °C for 60 min to obtain crystallized V 1-x Mo x o 2 film.

[0058] to get V 1-x Mo x o 2 The film was tested, and the phase composition of the film was checked by X-ray diffractometer ( figure 1 ); using a field emission scanning electron microscope to observe the morphology of the film ( figure 2 ); The variable temperature resis...

Embodiment 3

[0060] The precursor V(NMe 2 ) 4 and Mo(CO) 6 Heat to 50°C, and pulse alternately into the ALD reaction chamber, and the chamber temperature is controlled at 150°C. The gas flow is set to 300sccm, and the reaction pressure is 0.5mbar, O 2 The plasma power was set at 100W. an ALD VO 2 The pulse purge program is V(NEtMe) 4 (3s)—Ar(8s)—O 3 (0.6s)—Ar(3s), an ALD MoO 3 The pulse purge program for Mo(CO) 6 (1s)—Ar(4s)—O 2 (1s)—Ar(3s). Pass 7 ALD MoOs 3 Subcycle and 93 ALD VO 2 The sub-loop is repeated 5 times alternately to obtain MoO 3 Cycle ratio of 7% VO 2 / MoO 3 The nano-stack was incubated in a vacuum at 500°C for 60 minutes to obtain crystallized V 1-x Mo x o 2 film.

[0061] to get V 1-x Mo x o 2 The film was tested, and the phase composition of the film was checked by X-ray diffractometer ( figure 1 ); using a field emission scanning electron microscope to observe the morphology of the film ( figure 2 ); the transmittance ( Figure 5 ) and the calcul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com