An inorganic permeable fireproof insulation board

A fire-proof insulation board and permeable technology, applied in the directions of heat preservation, fire prevention, building components, etc., can solve the problems of the insulation board not being fixed firmly, the insulation board peeling off, easily peeling off, etc., to achieve good waterproof, improve fire resistance, and simple production process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

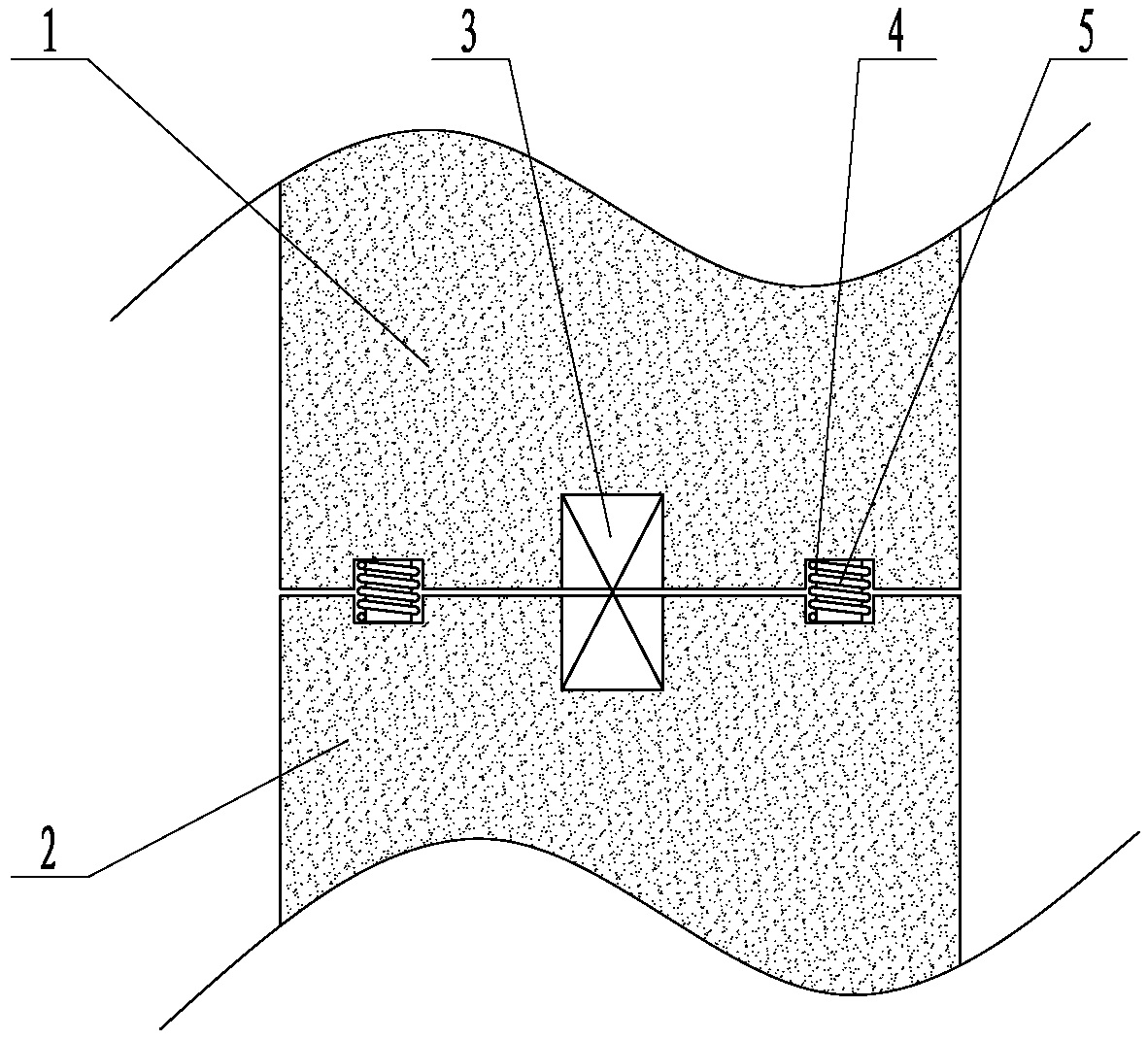

[0038] An inorganic permeable fireproof heat preservation board, comprising a heat preservation board body, the heat preservation board body comprising a heat preservation layer and an interface transition layer, the heat preservation layer comprising a heat preservation substrate, and the inside of the heat preservation substrate penetrates into nano-inorganic materials; the interface The transition layer is made of silicone waterproofing agent and penetrating crystalline waterproofing agent; the thickness is 2mm.

[0039] Its preparation method is:

[0040] ① Adjust the ratio of raw materials, the mass ratio of polystyrene particles to nano-silica and expandable graphite powder is 1:50:30, the particle size of polystyrene particles is 2.5-4.0mm, the surface of polystyrene particles The coating thickness is 200-450nm. After pre-delivery, wrapping, curing, molding and other processes, the thermal insulation substrate is obtained. ② After washing and drying the ceramic tile p...

Embodiment 2

[0042] An inorganic permeable fireproof heat preservation board, comprising a heat preservation board body, the heat preservation board body comprising a heat preservation layer and an interface transition layer, the heat preservation layer comprising a heat preservation substrate, and the inside of the heat preservation substrate penetrates into nano-inorganic materials; the interface The transition layer is made of silicone waterproofing agent and penetrating crystalline waterproofing agent; the thickness is 3mm.

[0043] Its preparation method is:

[0044] ① Adjust the ratio of raw materials. The mass ratio of polystyrene particles to nano-silica and expandable graphite powder is 1:60:30. After pre-sending, wrapping, curing, and molding processes, the insulation substrate is obtained. ②After washing and drying the ceramic tile polishing powder, mix the nano-aluminum oxide and the ceramic tile polishing powder evenly at a mass ratio of 3:1, and grind to make the particle siz...

Embodiment 3

[0046] An inorganic permeable fireproof heat preservation board, comprising a heat preservation board body, the heat preservation board body comprising a heat preservation layer and an interface transition layer, the heat preservation layer comprising a heat preservation substrate, and the inside of the heat preservation substrate penetrates into nano-inorganic materials; the interface The transition layer is made of silicone waterproofing agent and penetrating crystalline waterproofing agent; the thickness is 2mm.

[0047] Its preparation method is:

[0048] ① Adjust the ratio of raw materials. The mass ratio of polystyrene particles to nano-silica and expandable graphite powder is 1:80:50. After pre-sending, wrapping, curing, and molding processes, the insulation substrate is obtained. ② After washing and drying the ceramic tile polishing powder, mix the nano-aluminum oxide and the ceramic tile polishing powder evenly at a mass ratio of 5:1, and grind to make the particle si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com