Anion sanitary towel and manufacturing method thereof

A technology of negative ions and sanitary napkins, applied in the field of negative ion sanitary napkins and its preparation, can solve the problems of high production cost of sanitary napkins, frequent replacement of sanitary napkins, and lack of antibacterial function of sanitary napkins

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

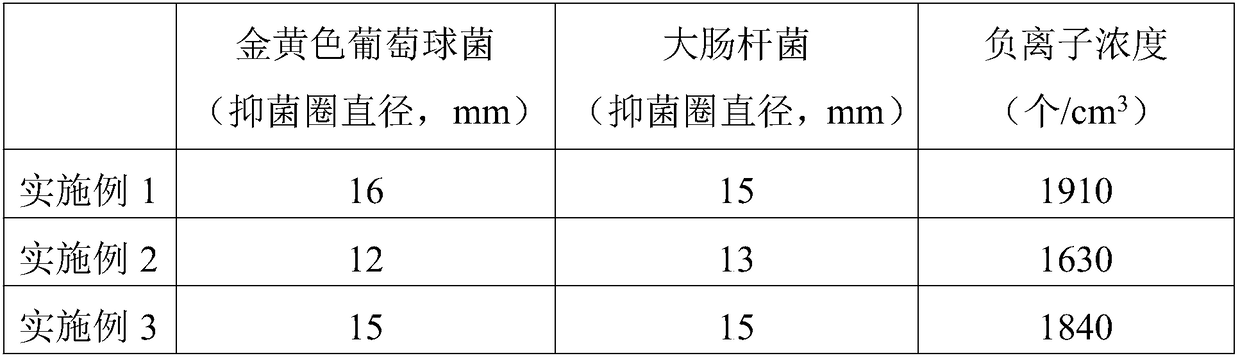

Examples

Embodiment 1

[0039] Negative ion sanitary napkins are sequentially composed of surface layer, negative ion functional chip, absorber, bottom film, release paper, envelope and quick and easy stickers. The negative ion functional chip is obtained by first dipping the chip in the negative ion finishing solution, then taking it out and drying it; the temperature of the dipping is 45°C, and the time is 30min; the temperature of the drying is 70°C, and the time is 3h; The mass ratio of the chip to the negative ion finishing solution is 1:5; the chip is a pure cotton non-woven fabric with a length of 15 cm and a width of 7 cm.

[0040] The negative ion finishing solution is prepared from the following raw materials in parts by weight: 5 parts of tourmaline powder, 4 parts of medical stone powder, 1 part of carbomer, 10 parts of dispersant, 0.1 part of copper citrate, and 90 parts of deionized water. All raw materials were added into deionized water and stirred at a speed of 300 rpm for 10 minutes...

Embodiment 2

[0044] Negative ion sanitary napkins are sequentially composed of surface layer, negative ion functional chip, absorber, bottom film, release paper, envelope and quick and easy stickers. The negative ion functional chip is obtained by first dipping the chip in the negative ion finishing solution, then taking it out and drying it; the temperature of the dipping is 45°C, and the time is 30min; the temperature of the drying is 70°C, and the time is 3h; The mass ratio of the chip to the negative ion finishing solution is 1:5; the chip is a pure cotton non-woven fabric with a length of 15 cm and a width of 7 cm.

[0045] The negative ion finishing solution is prepared from the following raw materials in parts by weight: 5 parts of tourmaline powder, 4 parts of medical stone powder, 1 part of carbomer, 10 parts of dispersant, 0.1 part of copper citrate, and 90 parts of deionized water. All raw materials were added into deionized water and stirred at a speed of 300 rpm for 10 minutes...

Embodiment 3

[0049] Negative ion sanitary napkins are sequentially composed of surface layer, negative ion functional chip, absorber, bottom film, release paper, envelope and quick and easy stickers. The negative ion functional chip is obtained by first dipping the chip in the negative ion finishing solution, then taking it out and drying it; the temperature of the dipping is 45°C, and the time is 30min; the temperature of the drying is 70°C, and the time is 3h; The mass ratio of the chip to the negative ion finishing solution is 1:5; the chip is a pure cotton non-woven fabric with a length of 15 cm and a width of 7 cm.

[0050] The negative ion finishing solution is prepared from the following raw materials in parts by weight: 5 parts of tourmaline powder, 4 parts of medical stone powder, 1 part of carbomer, 10 parts of dispersant, 0.1 part of silver citrate, and 90 parts of deionized water. All raw materials were added into deionized water and stirred at a speed of 300 rpm for 10 minutes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com