Nanometer composite material as well as preparation method and application thereof

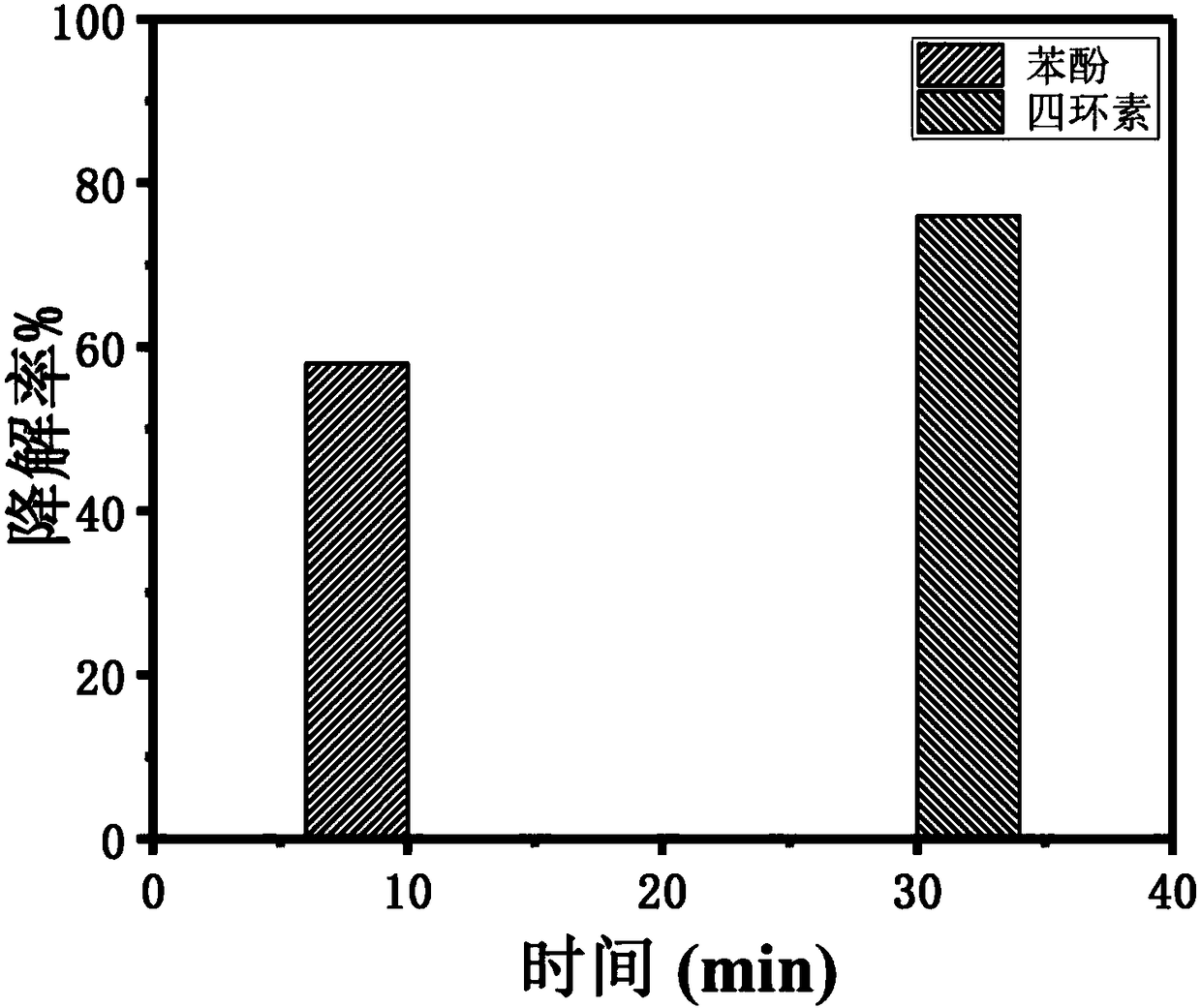

A technology of nanocomposite materials and mixed solutions, which is applied in the field of nanomaterials to achieve good degradation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

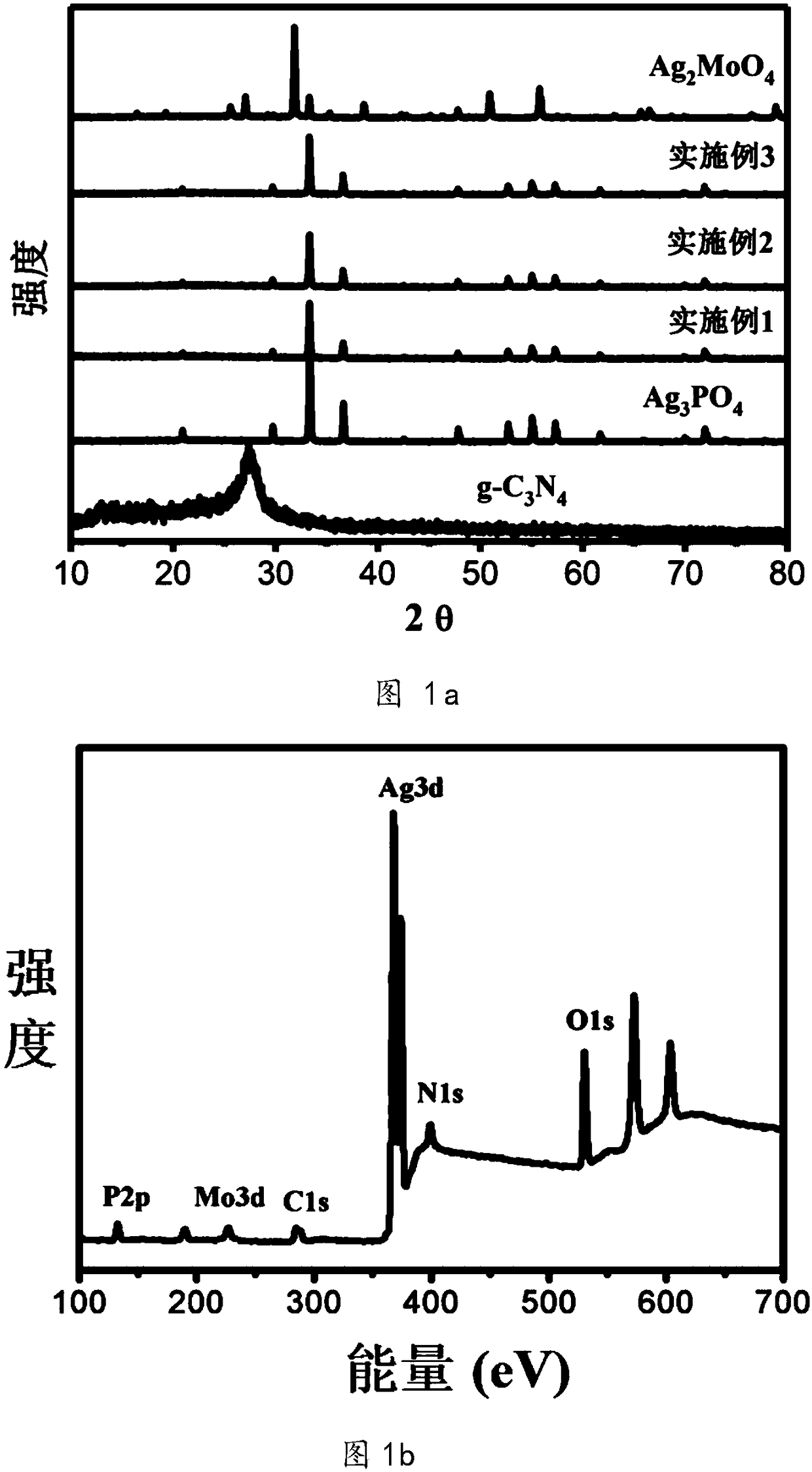

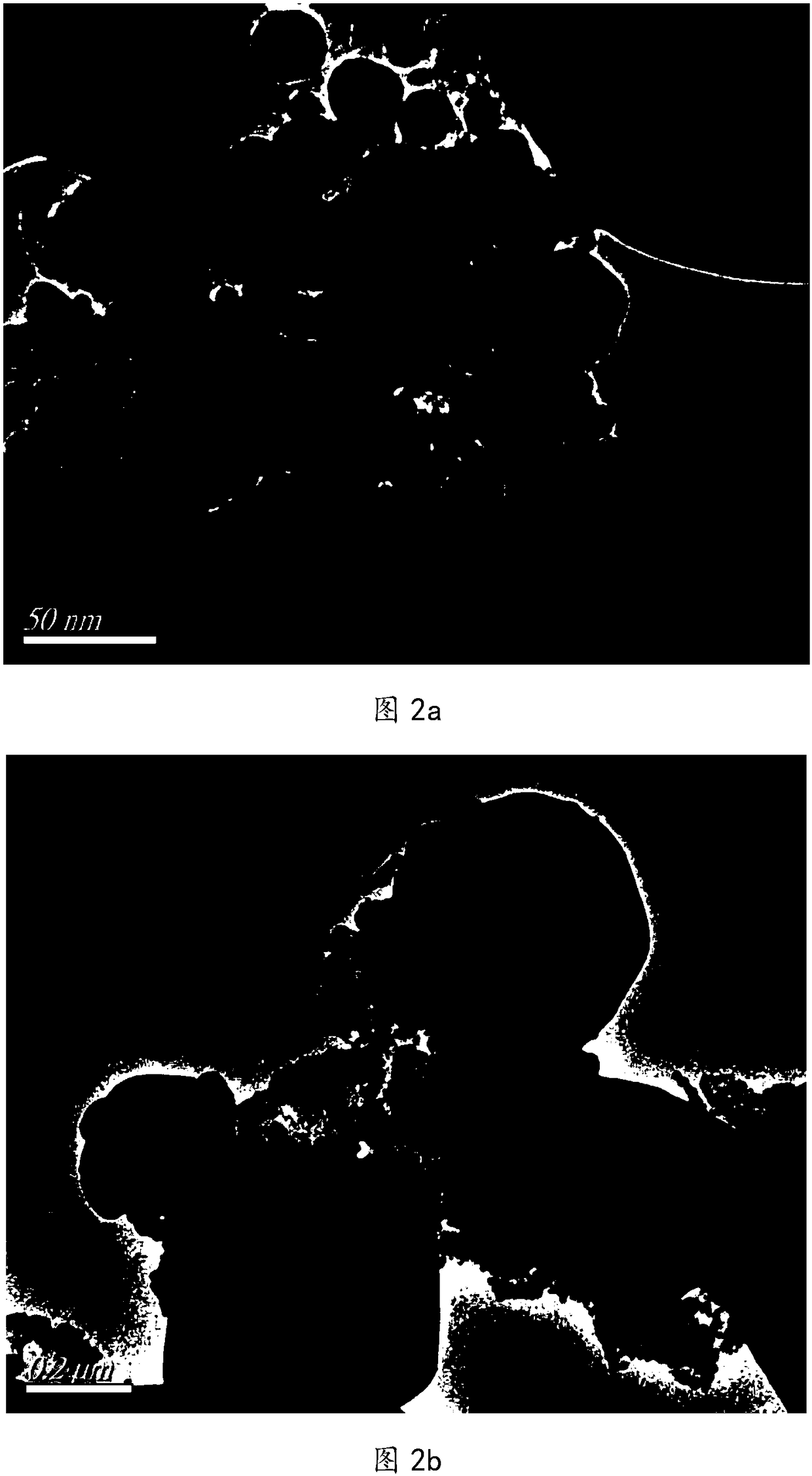

Embodiment 1

[0030] (1) Add 10% ammonia solution dropwise to 40 mL of AgNO with a concentration of 2 mol / L 3 In the solution, silver ammonia solution is obtained;

[0031] 0.09g g-C 3 N 4 Add above-mentioned silver-ammonia solution, form graphene-silver-ammonia mixed solution after continuous stirring 10h under the condition of avoiding light;

[0032] (2) 0.01mol NaH 2 PO 4 with 0.0012mol Na 2 m o o 4 Dissolve in 50mL of deionized water, sonicate for 1h to form a mixed solution, then add 1g of cetyltrimethylammonium bromide to the solution, and continue magnetic stirring for 3h. Under the condition of maintaining magnetic stirring, the above solution was added dropwise to the graphene-silver ammonia mixed solution in step (1), and the rate of addition was controlled at 2 s / drop. After the reaction was complete, the stirring was continued for 6 hours, the obtained dark green precipitate was repeatedly washed and centrifuged with ethanol and deionized water, and finally the sample w...

Embodiment 2

[0034] (1) Add 10% ammonia solution dropwise to 50mL of AgNO 3 In the solution, the concentration thereof is 1mol / L, and then 0.42g of graphene is added to the above solution, and the graphene-silver ammonia mixed solution is formed after continuous stirring for 10h under the condition of avoiding light.

[0035] (2) 0.01mol(NH 4 ) 2 HPO 4 With 0.002mol (NH4) 2 MoO 4 Dissolve in 50 mL of deionized water, and form a mixed solution after ultrasonication for 1 h, then add 0.4 g of polyethylene glycol to the above solution, and continue magnetic stirring for 3 h. Under the condition of maintaining magnetic stirring, the above solution was added dropwise into the solution (1), and the dropping rate was controlled to be 3 drops / s. After the reaction was complete, the stirring was continued for 6 h, and the obtained dark green precipitate was repeatedly washed and centrifuged with ethanol and deionized water, and finally the sample was placed in a 60 ° vacuum oven and dried over...

Embodiment 3

[0037] (1) Add 10% ammonia solution dropwise to 60mL of AgNO 3 In the solution, the concentration thereof is 1mol / L, and then 0.73g of graphene is added into the above solution, and the graphene-silver ammonia mixed solution is formed after continuous stirring for 10h under the condition of avoiding light.

[0038] (2) 0.01molNa 2 HPO 4 with 0.003mol MoO 3 Dissolve in 50mL of deionized water, sonicate for 1h to form a mixed solution, then add 0.5g of polyvinylpyrrolidone to the above solution, and continue magnetic stirring for 3h. Under the condition of maintaining magnetic stirring, the above solution was added dropwise into the solution (1), and the dropping rate was controlled to be 2 drops / s. After the reaction was complete, the stirring was continued for 6 h, and the obtained dark green precipitate was repeatedly washed and centrifuged with ethanol and deionized water, and finally the sample was placed in a 60 ° vacuum oven and dried overnight for 8 h, and the yield w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com