Machining method of ultrafine-grain high-strength magnesium alloy sheet

A processing method and technology for magnesium alloys, applied in metal rolling and other directions, can solve the problems of high cost of rare earth elements, limited natural reserves, unrealistic heavy rare earths, etc., achieve high yield, reduce energy consumption and cost, and improve rolling. The effect of pass reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] In this example, AZ91 (Mg-9wt%Al-1wt%Zn) magnesium alloy is used as the test material.

[0065] Firstly, the as-cast AZ91 magnesium alloy was processed into a cuboid block of 49mm×49mm×100mm by wire cutting.

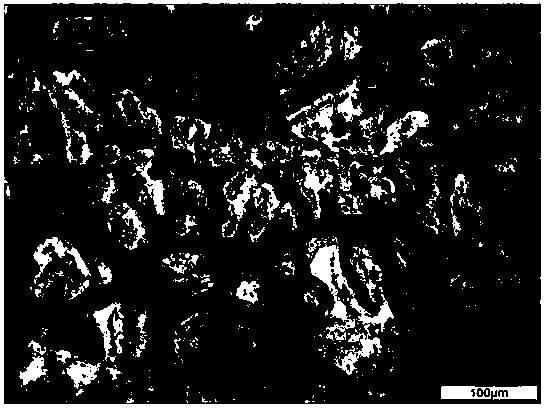

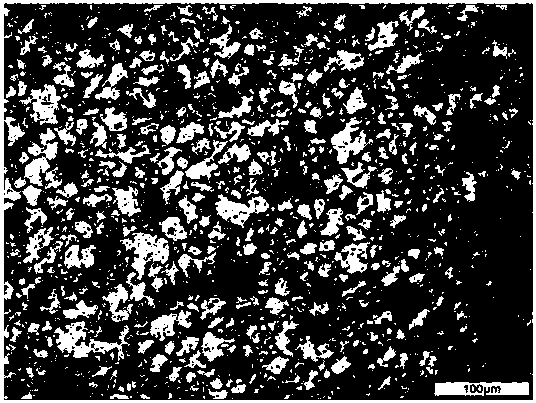

[0066] figure 1 It is the metallographic structure of as-cast AZ91 without any treatment, showing coarse dendrites. Then put it in the RD-ECAP mold and heat it to 250°C for 30-60 minutes, and perform 16 passes of ECAP processing. After ECAP processing, the average grain size is about 20 microns, such as figure 2 .

[0067] The mechanical properties of the prepared ultra-fine grained AZ91 magnesium alloy and the untreated as-cast AZ91 magnesium alloy were tested, and the results are as follows image 3 Shown: As-cast AZ91 has a yield strength of 100Mpa, an ultimate strength of 220Mpa, and a maximum elongation of 14.5%. The AZ91 magnesium alloy processed by ECAP has a longitudinal yield strength of 200Mpa, an ultimate strength of 390Mpa, and a maximum elongatio...

Embodiment 2

[0073] In this embodiment, AZ91 (Mg-9wt%Al-1wt%Zn) magnesium alloy is used.

[0074] The difference from Example 1 is that the holding temperature in the first step is 350°C, and the holding time is 60 minutes. The conditions are the same as in Case 1. The yield strength of the obtained magnesium alloy sheet along the rolling direction is 410MPa, the ultimate strength is 459Mpa, and the maximum elongation is 10%, and the yield strength along the normal direction of rolling is 425MPa, the ultimate strength is 478MPa, and the maximum elongation is 9 %.

Embodiment 3

[0076] In this embodiment, AZ91 (Mg-9wt%Al-1wt%Zn) magnesium alloy is used.

[0077] The difference from Example 1 is that the holding temperature in the first step is 350°C, and the holding time is 60 minutes. The conditions are the same as in Case 1. The yield strength of the obtained magnesium alloy sheet along the rolling direction is 450MPa, the ultimate strength is 491Mpa, and the maximum elongation is 10.5%. The yield strength along the normal direction of rolling is 390MPa, the ultimate strength is 419MPa, and the maximum elongation is 10%. %.

[0078] From the above examples, it can be seen that the yield strength of the AZ91 magnesium alloy plate after equal channel angular extrusion, extrusion blanking and rolling combined processing is 390MPa, the ultimate strength is above 450MPa, and the maximum elongation is greater than 6.8%. High-strength magnesium alloy sheets can be obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com