Polypropylene fiber whole-coral aggregate concrete and preparation method thereof

A polypropylene fiber and concrete technology, which is applied in the field of building materials, can solve the problems such as the development limitation of coral aggregate concrete, low strength of coral aggregate concrete, harsh natural environment, etc., so as to strengthen the construction of remote sea island reef engineering and improve poor working performance. , the effect of improving porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

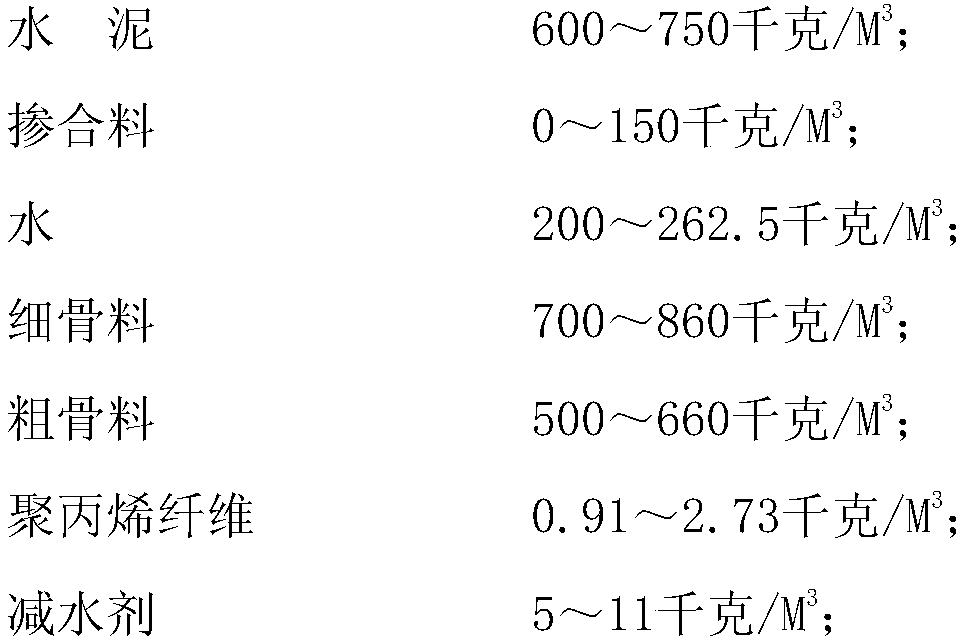

[0036] 1. The weight ratio of raw materials per cubic meter is:

[0037] 42.5 Ordinary Portland cement 750kg;

[0038] Natural coral sand 735.2kg, particle size 0.15-5mm, fineness modulus 2.88, bulk density 1131kg / m 3 ;

[0039] The crushed coral reef gravel is 649.4kg, continuously graded from 5 to 20mm, and the bulk density is 999kg / m 3 , 1 hour water absorption rate is 12%;

[0040] 225kg of tap water;

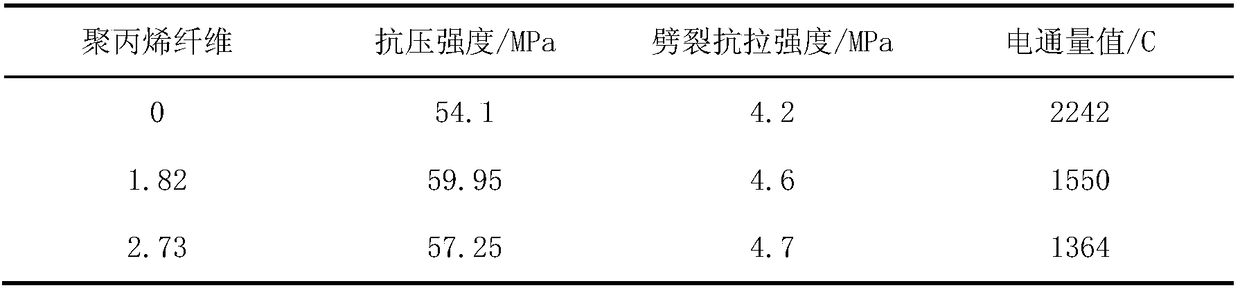

[0041] 1.82kg and 2.73kg of bundled monofilament polypropylene fibers with a length of 12mm and a tensile strength of 725MPa;

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com