Block-copolymerized carbodiimide compound and preparation method thereof

A technology of copolymerizing carbodiimide and carbodiimide, which is applied in the direction of organic chemistry, can solve the problems of low reactivity, yellow color, and difficulty in inhibiting aromatic polymerization carbodiimide, so as to ensure long-term hydrolysis resistance , Reduce viscosity increase, inhibit degradation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] 1) In a nitrogen atmosphere, add 8.58kg of triisopropylphenyl diisocyanate and 0.0429kg of catalyst MPPO, and carry out polycondensation reaction at about 180°C to obtain polytriisopropylphenylcarbodiimide with a degree of polymerization of about 2 .

[0038] 2) In a nitrogen atmosphere, 10.48kg of 4,4'-dicyclohexylmethane diisocyanate and 0.0524kg of catalyst MMPO were subjected to polycondensation reaction at 160°C to obtain a poly-4,4'-bicyclo with a degree of polymerization of about 3 Hexylmethanecarbodiimide. Cool the reaction down to 120°C, add 0.9kg of chain extender 1-amino-3-propanol at a molar ratio of 1.2:1, react for 1h, complete half-capping to obtain an intermediate product, and add polytriisopropyl Benzene carbodiimide, add 0.008 kg of stannous octoate catalyst, raise the temperature to 140 ° C, and react for 1.5 hours to obtain 15.6 kg of white powder product, which is a block copolymerized carbodiimide compound.

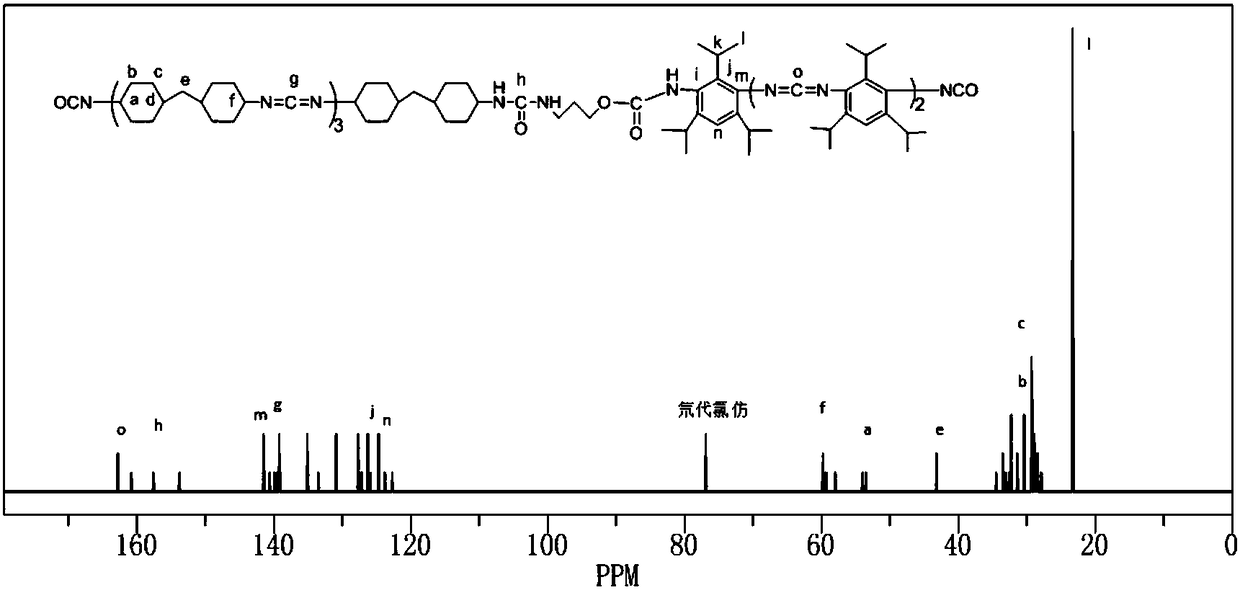

[0039] The carbon spectrum of the pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com