A kind of paraffin emulsion and preparation method thereof

A technology of paraffin emulsion and solid paraffin, applied in the field of chemical industry, can solve the problems of high product viscosity, complicated process, disadvantage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

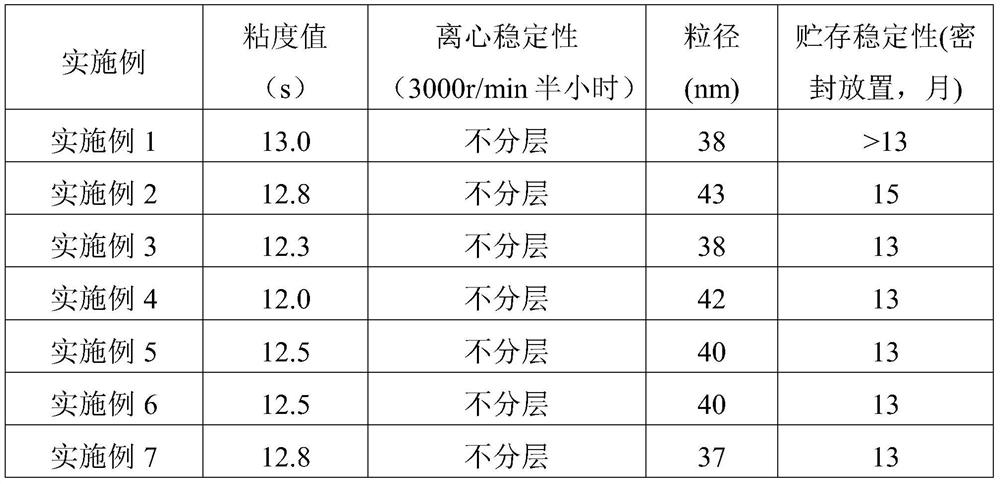

Embodiment 1

[0027] This example is used to illustrate the paraffin emulsion provided by the present invention and its preparation method.

[0028] Add solid paraffin 70kg (mass percentage is 38.779%), compound emulsifier 10.51kg (5.822%) in the reactor that is equipped with stirring paddle, wherein sorbitan monostearate 6.40kg (accounting for compound emulsifier mass percentage 60.9%), fatty alcohol polyoxyethylene ether-20 2.98kg (accounting for 28.35% of compound emulsifier mass percent), polyethylene glycol stearate 1.13kg (accounting for compound emulsifier mass percent 10.75%), heated to 80°C, after stirring evenly, add 20kg of water drop by drop, the emulsion forms a water-in-oil system, add 40kg of water to change the emulsification system from water-in-oil to oil-in-water, add 40kg of water, keep at 80°C for half an hour, cool down and discharge. The viscosity of the product is 13.0s, no delamination after centrifugation at 3000r / min for half an hour, the particle size is 38nm, go...

Embodiment 2

[0030] This example is used to illustrate the paraffin emulsion provided by the present invention and its preparation method.

[0031]Add solid paraffin 70kg (mass percentage is 38.779%), compound emulsifier 10.51kg (5.822%) in the reactor that is equipped with stirring paddle, wherein sorbitan monostearate 6.20kg (accounting for compound emulsifier mass percentage 58.99%), fatty alcohol polyoxyethylene ether-20 0.81kg (accounting for 7.71% of compound emulsifier mass percentage), polyethylene glycol stearate 3.5kg (accounting for compound emulsifier mass percentage 33.30%), heating to 80°C, after stirring evenly, add 20kg of water drop by drop, the emulsion forms a water-in-oil system, add 40kg of water to change the emulsification system from water-in-oil to oil-in-water, add 40kg of water, keep at 80°C for half an hour, cool down and discharge. The viscosity of the product is 12.8s, no delamination after centrifugation at 3000r / min for half an hour, the particle size is 43n...

Embodiment 3

[0033] This example is used to illustrate the paraffin emulsion provided by the present invention and its preparation method.

[0034] Add solid paraffin 70kg (mass percentage is 38.779%), compound emulsifier 10.51kg (5.822%) in the reactor that is equipped with stirring paddle, wherein sorbitan monostearate 6.20kg (accounting for compound emulsifier mass percentage 58.99%), fatty alcohol polyoxyethylene ether-20 1.05kg (accounting for 9.99% of compound emulsifier mass percent), polyethylene glycol stearate 3.26kg (accounting for compound emulsifier mass percent 31.02%), heated to 80°C, after stirring evenly, add 20kg of water drop by drop, the emulsion forms a water-in-oil system, add 40kg of water to change the emulsification system from water-in-oil to oil-in-water, add 40kg of water, keep at 80°C for half an hour, cool down and discharge. The viscosity of the product is 12.3s, no delamination after centrifugation at 3000r / min for half an hour, the particle size is 38nm, go...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com