Flexible printed circuit protection glue and preparation method thereof

A technology of protective glue and glue phase, applied in the direction of adhesives, adhesive additives, non-polymer adhesive additives, etc., can solve the problem of poor heat resistance and aging resistance of flexible circuit boards, three-layer glued flexible board base Limitations in the field of materials, affecting the electrical properties of FPC flexible boards, etc., to achieve the effect of being conducive to industrialized large-scale production, simple and easy preparation methods, and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

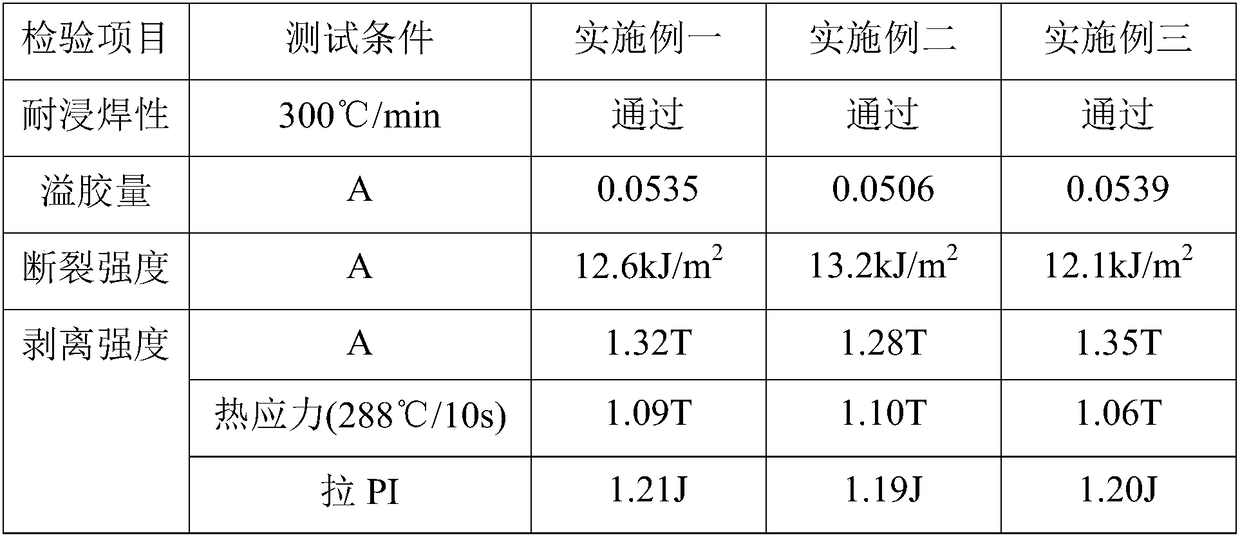

Examples

preparation example Construction

[0022] In addition, for the protective glue provided by the present invention, the applicant specially designed a preparation method, including the following steps:

[0023] S101: weighing each raw material component in proportion, and then grinding until the particle size of each raw material is less than or equal to 100 nm.

[0024] S102: Stir the ground raw material components evenly under sealed conditions to obtain a protective glue.

[0025] Describe below in conjunction with specific implementation manner:

Embodiment 1

[0027] The invention provides a flexible printed circuit protective adhesive. The raw material components are calculated in parts by weight, including: 3300 parts by weight of aluminum oxide, 3600 parts by weight of iron oxide, 6500 parts by weight of plastic, 3500 parts by weight of metal glue, and 420 parts by weight of softener , 16 parts by weight of dibutyltin dilaurate active liquid, 105 parts by weight of A900, 140 parts by weight of OPM800, and 10 parts by weight of KBM438.

[0028] Protective glue is prepared according to the method provided by the invention, comprising the following steps:

[0029] S101: weighing each raw material component in proportion, and then grinding until the particle size of each raw material is less than or equal to 100 nm.

[0030] S102: Stir the ground raw material components evenly under sealed conditions to obtain a protective glue.

Embodiment 2

[0032] The invention provides a flexible printed circuit protective adhesive. The raw material components are calculated in parts by weight, including: 3220 parts by weight of aluminum oxide, 4000 parts by weight of iron oxide, 6000 parts by weight of plastic, 4000 parts by weight of metal glue, and 390 parts by weight of softener , 20 parts by weight of dibutyltin dilaurate active solution, 95 parts by weight of A900, 160 parts by weight of OPM800, and 8 parts by weight of KBM438.

[0033] Protective glue is prepared according to the method provided by the invention, comprising the following steps:

[0034] S101: weighing each raw material component in proportion, and then grinding until the particle size of each raw material is less than or equal to 100 nm.

[0035] S102: Stir the ground raw material components evenly under sealed conditions to obtain a protective glue.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com