Plant-source environment-friendly fluorescent carbon quantum dots as well as preparation method and application of plant-source environment-friendly fluorescent carbon quantum dots

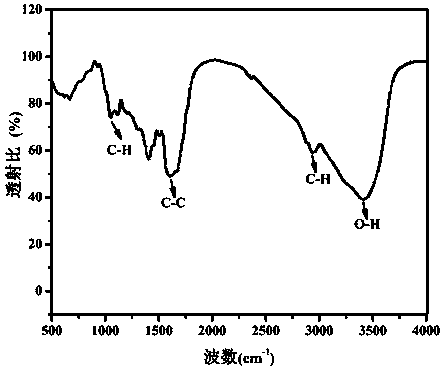

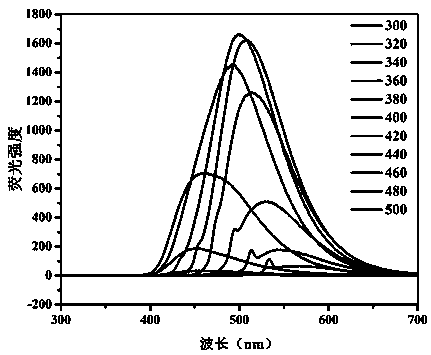

A technology of carbon quantum dots and fluorescent quantum yield, applied in the direction of fluorescence/phosphorescence, chemical instruments and methods, nano-carbon, etc., can solve the problems of low yield and few fluorescent active sites of carbon quantum dots, and achieve low biological toxicity , good imaging effect, good biocompatibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] A method for preparing plant-derived nontoxic and environmentally friendly fluorescent carbon quantum dots, comprising the following steps:

[0016] (1) Select mature fresh fruit of seedless Rosa roxburghii, wash it thoroughly with distilled water, remove the fruit stem and persistent calyx for later use;

[0017] (2) Mix the deionized water and Rosa roxburghii in a mass ratio of 3, and place them in a blender to grind them thoroughly to obtain a homogenate. Weigh 20.0 g of the homogenate, place it in a 100 ml reactor liner, and vibrate ultrasonically for 5 min to fully disperse the material in the homogenate. Then, the hydrothermal method was used to react at 140 °C for 8 h to obtain a preliminary fluorescent carbon quantum dot solution;

[0018] The preliminary fluorescent carbon quantum dot solution was ultracentrifuged at 12000 r / min for 10 min, the supernatant was filtered with a syringe filter, and the supernatant was taken to obtain the fluorescent carbon quantu...

Embodiment 2

[0020] A method for preparing plant-derived nontoxic and environmentally friendly fluorescent carbon quantum dots, comprising the following steps:

[0021] (1) Select mature fresh fruit of seedless Rosa roxburghii, wash it thoroughly with distilled water, remove the fruit stem and persistent calyx for later use;

[0022] (2) Mix the deionized water and Rosa roxburghii at a mass ratio of 0.5, and place them in a blender to grind them sufficiently to obtain a homogenate. Weigh 70.0 g of the homogenate, place it in a 100 ml reactor liner, and vibrate ultrasonically for 10 min to fully disperse the material in the homogenate. Then, the hydrothermal method was used to react at 200 °C for 24 h to obtain a preliminary fluorescent carbon quantum dot solution;

[0023] The preliminary fluorescent carbon quantum dot solution was ultracentrifuged at 20,000 r / min for 30 min, and the supernatant was filtered with a syringe filter, and the fluorescence retention time of carbon quantum dots...

Embodiment 3

[0025] A method for preparing plant-derived nontoxic and environmentally friendly fluorescent carbon quantum dots, comprising the following steps:

[0026] (1) Select mature fresh fruit of seedless Rosa roxburghii, wash it thoroughly with distilled water, remove the fruit stem and persistent calyx for later use;

[0027] (2) Mix the deionized water and Rosa roxburghii at a mass ratio of 0.8, and place them in a blender to grind them sufficiently to obtain a homogenate. Weigh 56.00 g of the homogenate, place it in a 100 ml reactor liner, and vibrate ultrasonically for 10 min to fully disperse the material in the homogenate. Then, the hydrothermal method was used to react at 220 °C for 12 h to obtain a preliminary fluorescent carbon quantum dot solution;

[0028] The preliminary fluorescent carbon quantum dot solution was ultracentrifuged at 18,000 r / min for 30 min, and the supernatant was filtered with a syringe filter, and the fluorescence retention time of carbon quantum dot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com