Method for preparing novel magnesium-based composite by ultrasonic assisted mechanical mixing

A technology of auxiliary machinery and composite materials, which is applied in the field of magnesium alloys, can solve the problems of carbon nanotube surface inactivity, weak bonding, and fragile interface, and achieve the effects of increasing stirring speed, preventing oxidative combustion, and reducing pores and inclusions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is further illustrated in conjunction with specific examples of implementation as follows, the Mg-Al-Si-Sb-Ca alloy is composed of the following components in weight percentage: 8%Al, 2%Si, 0.75%Sb, 0.5%Ca, and the balance is magnesium , the added reinforcement is 1% carbon nanotubes.

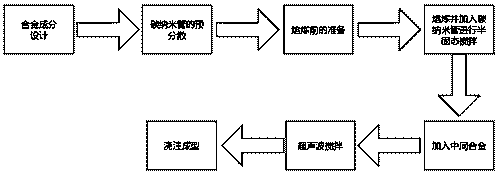

[0019] Its preparation method is:

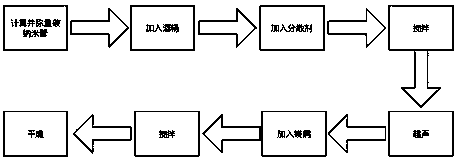

[0020] (1) Calculate and weigh the carbon nanotubes into the alcohol, add a certain amount of chemical dispersant, then use the stirrer to stir the carbon nanotube alcohol solution, and then put the carbon nanotube alcohol solution into the ultrasonic pool for ultrasonic Treat for 3 hours until a stable suspension of carbon nanotubes is obtained, add an appropriate amount of magnesium chips to the carbon nanotube alcohol solution, stir for 3 hours, and finally dry naturally in a fume hood.

[0021] (2) Clean the impurities on the melting tools such as graphite crucible, stirring paddle, ultrasonic tool rod, etc., and put them int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com