Quick drying type digital printing dispersing ink as well as preparation method and application thereof

A technology of digital printing and dispersing ink, applied in transfer printing method, printing, dyeing method, etc., can solve the problem of water-based dispersing ink being difficult to volatilize and dry in time, achieve good industrial application and promotion prospects, reduce temperature and time, print good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

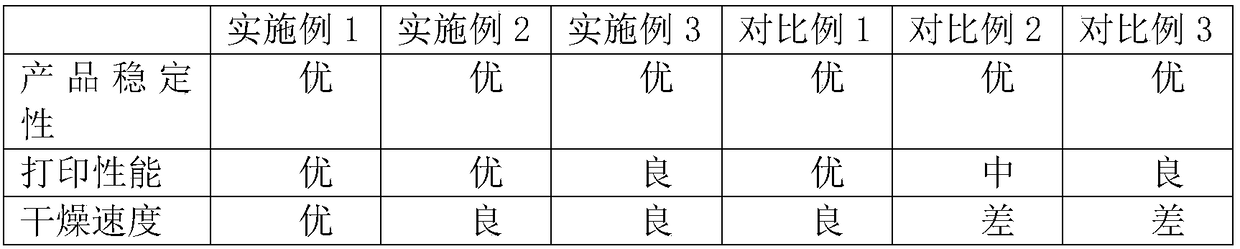

Examples

Embodiment 1-3 and comparative example 1-3

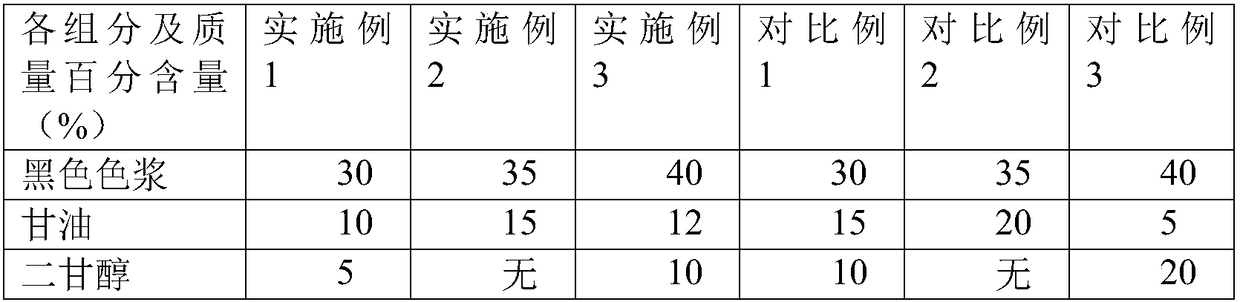

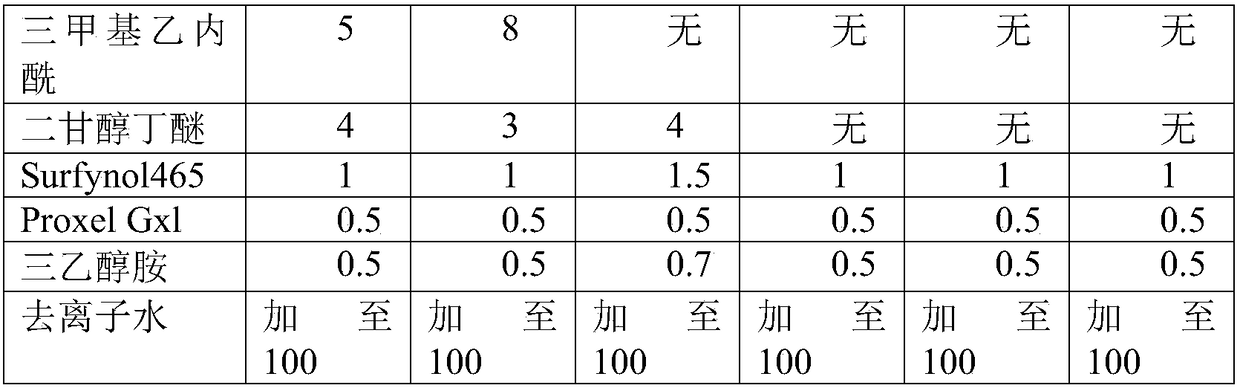

[0034] In the present invention, the preparation method of the target product in the described examples and comparative examples is as follows: mix each component uniformly according to the ratios in Table 1, and after stirring for 2 hours at a speed of 60 rpm, use a pore size of 0.22 μm The filter membrane (PP membrane) is filtered, and the obtained filtrate is the described target product.

[0035] In the embodiments of the present invention and comparative examples,

[0036] The black color paste refers to the color paste configured with Disperse Blue 359, Disperse Yellow 54 and Disperse Brown 26 in a ratio of 1:1:8;

[0037] Described Surfynol465 is provided by gas products company (airproduct company);

[0038] The Proxel Gxl is provided by Lonza Company.

[0039] Table 1

[0040]

[0041]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com