Blades, blade synergistic system and wind generating set

A technology for wind turbines and blades, which is applied to wind turbines, wind energy power generation, and wind turbines in the same direction as the wind, can solve the problems of unfavorable structural integrity, limited opening effect, and large load, so as to prevent airflow separation. , the effect of increasing survivability and reducing load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to enable those skilled in the art to better understand the present invention, specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

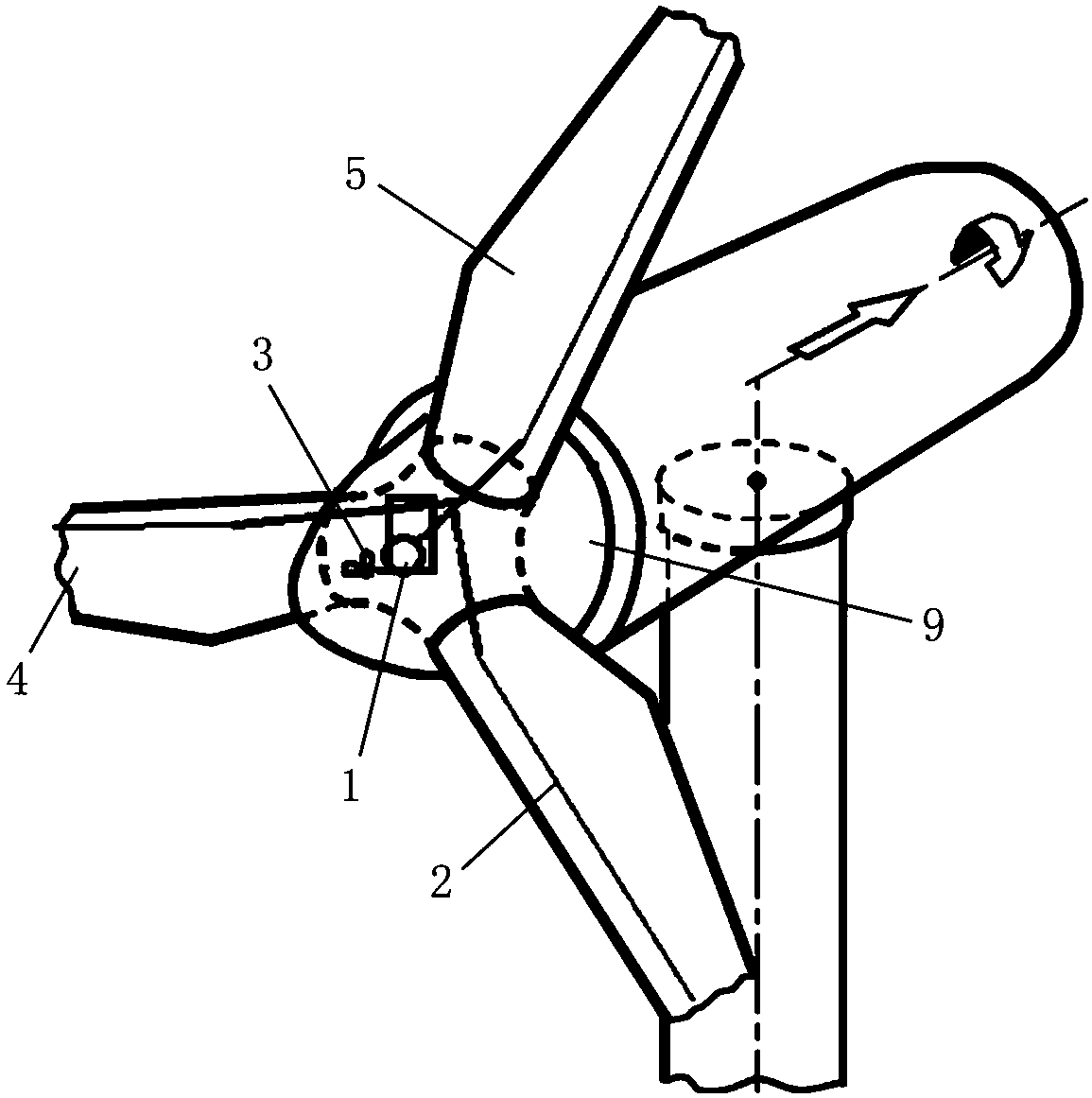

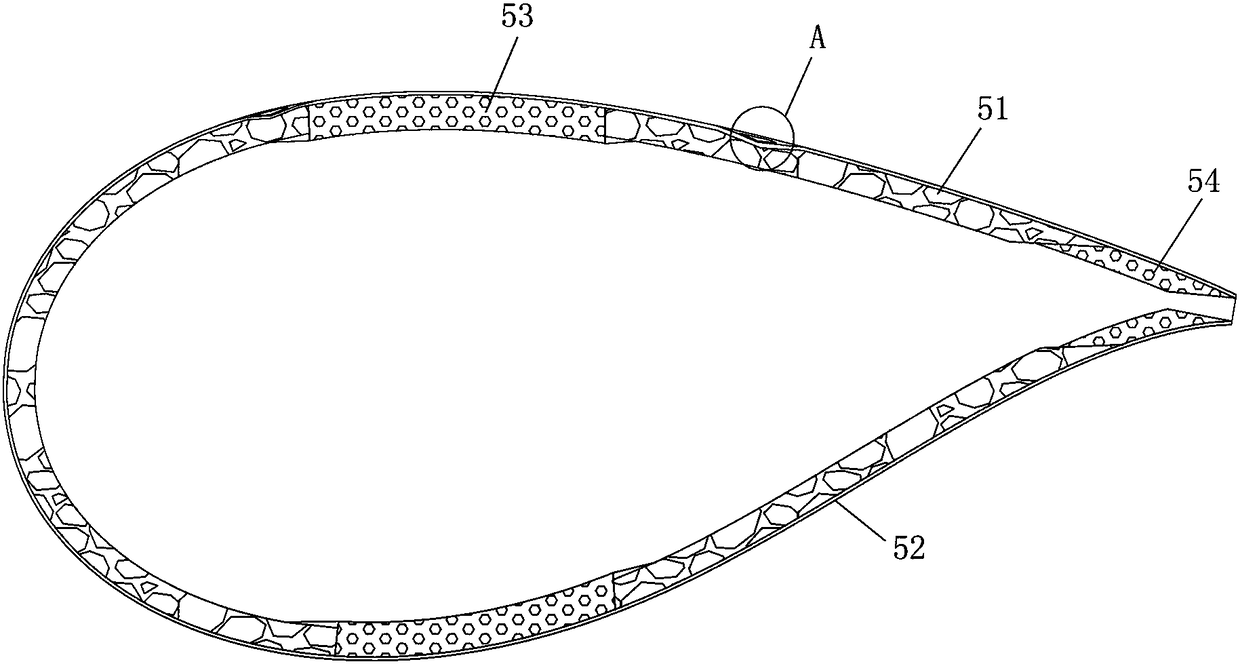

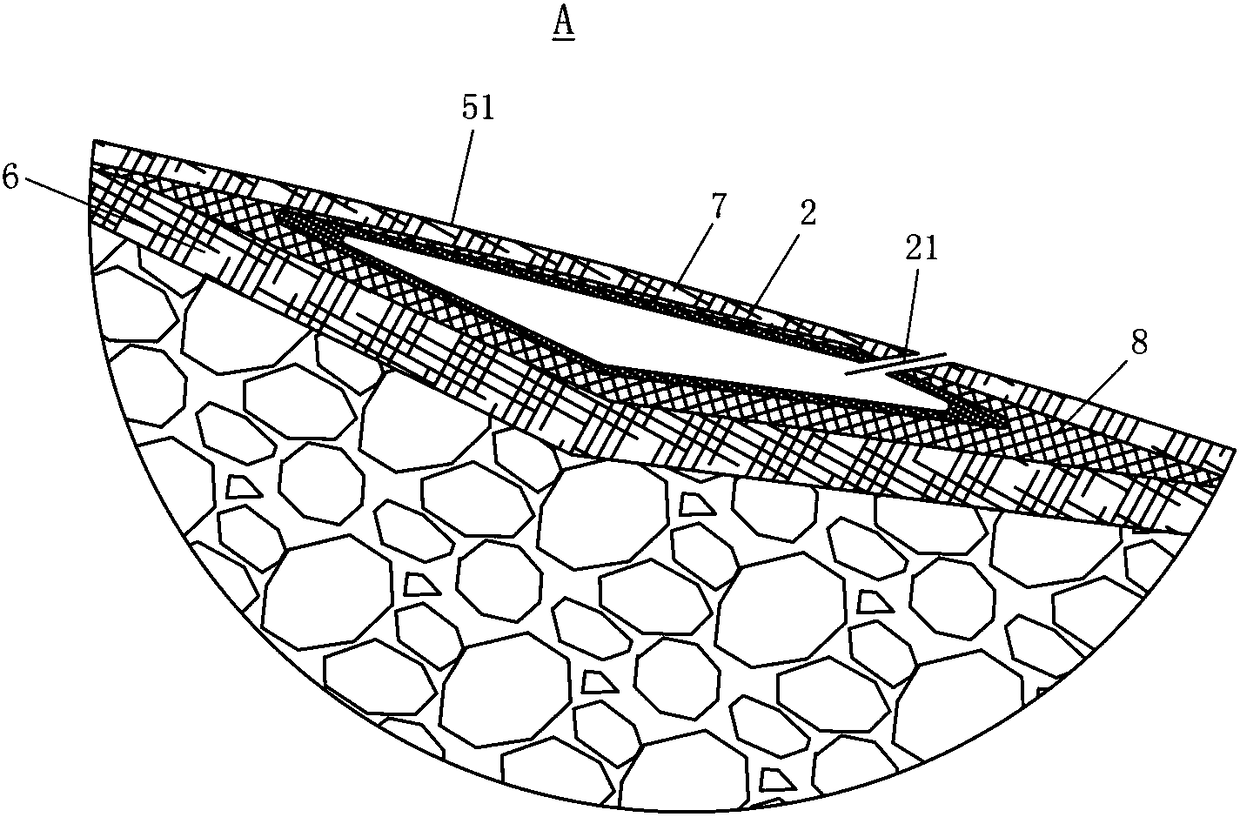

[0027] refer to Figure 1 to Figure 3 ,in, figure 1 is a schematic diagram of a blade synergistic system according to an embodiment of the present invention, figure 2 is a schematic diagram of the installation position of the drainage tube according to an embodiment of the present invention; image 3 yes figure 2 Partial enlarged view of part A in .

[0028] According to an embodiment of the present invention, a blade 5 is provided, the blade 5 has a suction surface 51 and a pressure surface 52 , and at least the suction surface 51 of the suction surface 51 and the pressure surface 52 is provided with a drainage pipe 2 . The drainage pipe 2 may be pre-embedded at least on the suction surface 51 of the blade, that is, the drainage pipe 2 may be pre-emb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com