Cow bedding regenerating equipment

The technology of regeneration equipment and bedding material is applied in the field of cow dung material regeneration equipment, which can solve the problems of long time and uneven fermentation of cow dung fermentation process, and achieve the effects of compact structure, low operation cost and light weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with specific examples, but the present invention is not limited by the examples.

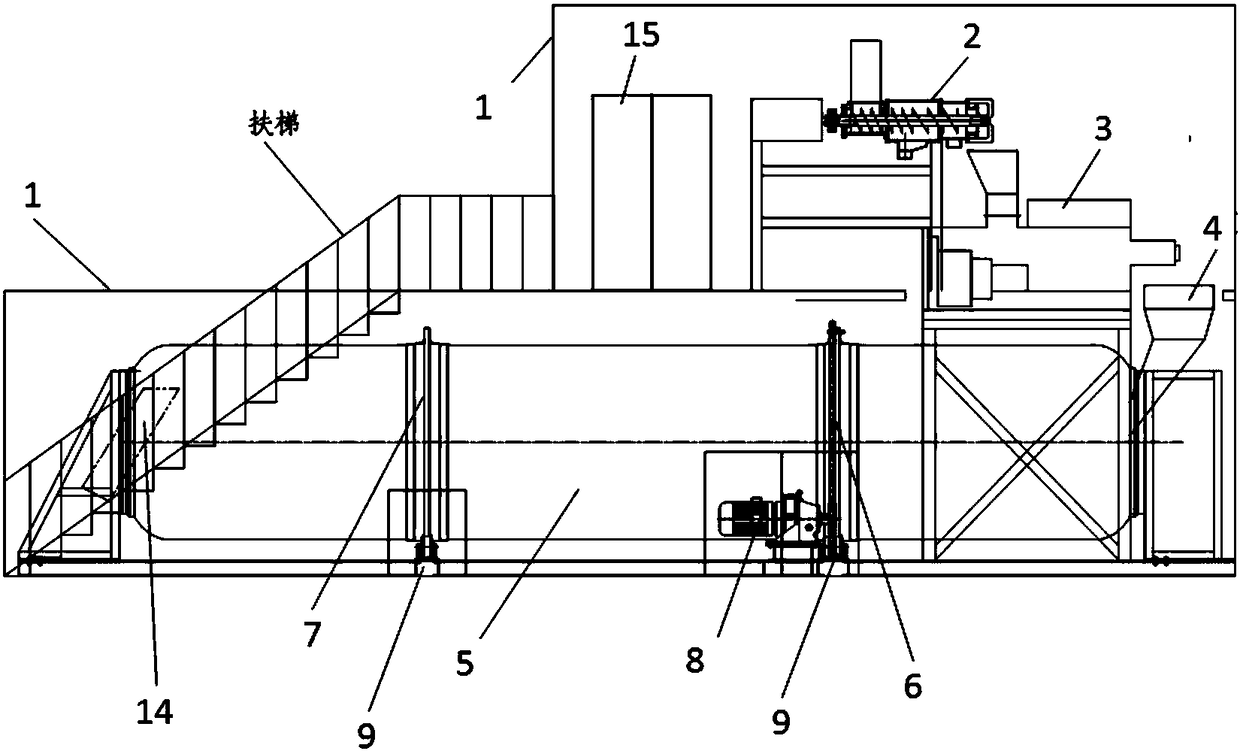

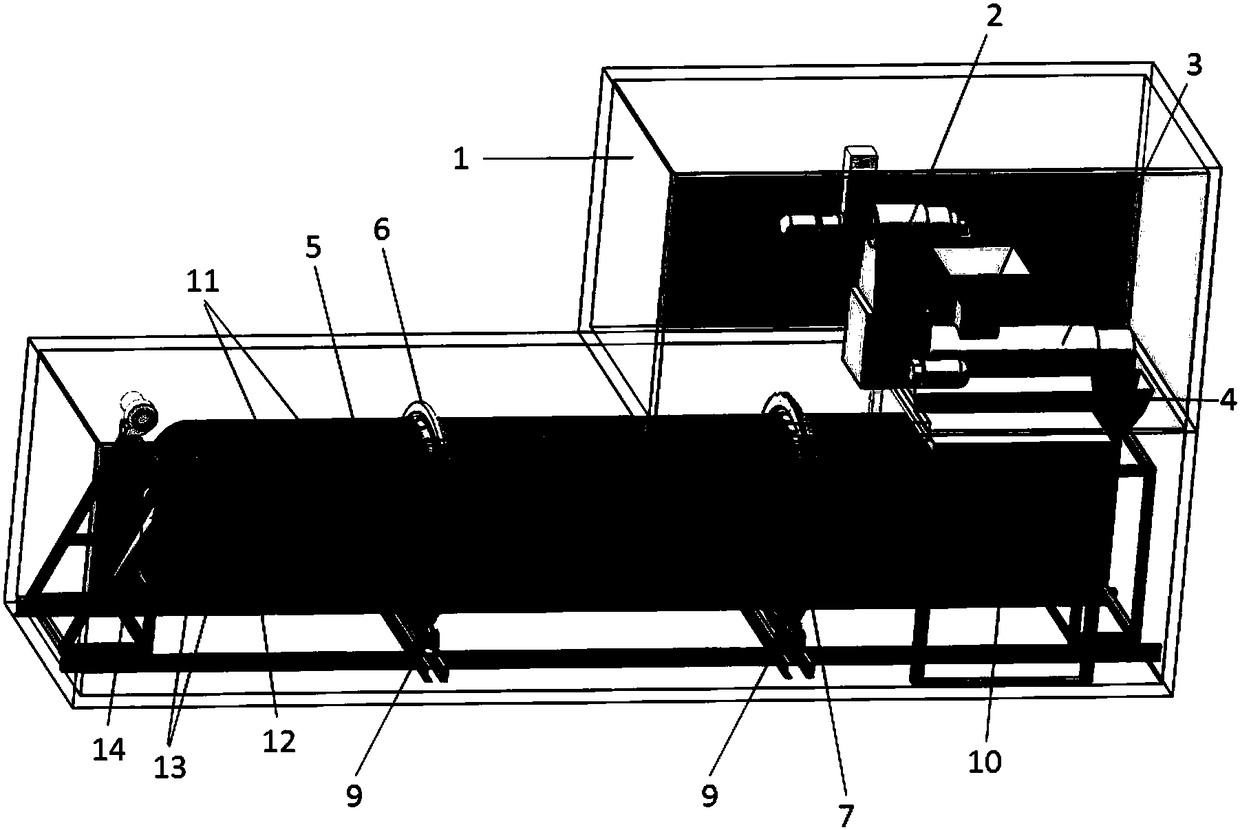

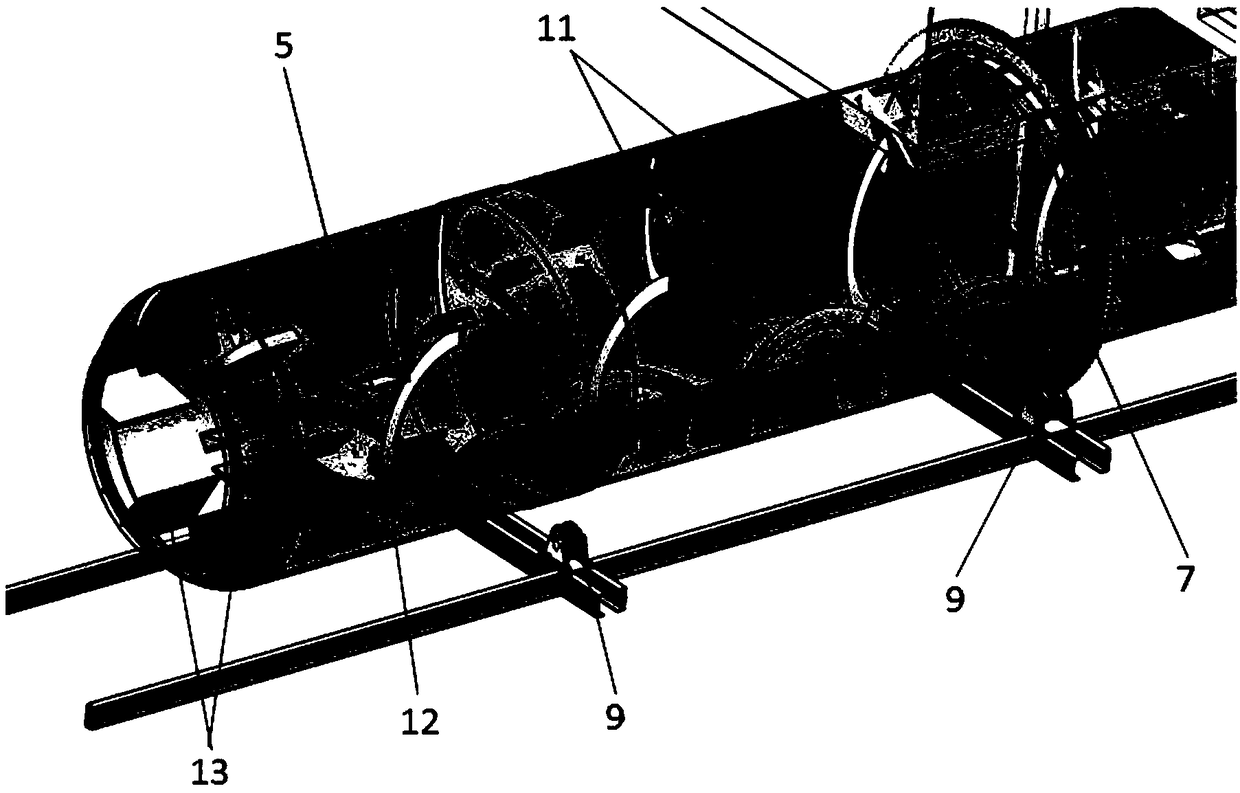

[0033] like Figure 1-5As shown, a kind of bedding regeneration equipment for dairy cows in this embodiment, the bedding regeneration equipment for cows includes an insulated box 1 and a solid-liquid separator 2 located inside the insulated box 1, a squeeze dehydrator 3, Feed hopper 4, horizontal rotary fermenter 5, driving motor 8 and discharge tank 14; the solid material outlet of the solid-liquid separator 2 is located directly above the feed inlet of the extrusion dehydrator 3; the extrusion The discharge port of the dehydrator 3 is located directly above the feed hopper 4; the discharge end of the feed hopper 4 is inserted into the horizontal rotary fermenter 5; the outer wall of the horizontal rotary fermenter 5 is fixed with a belt A toothed rolling ring 6 and a non-toothed rolling ring 7; the drive motor 8 driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com