Preparation as well as adsorption and catalytic degradation application of high-strength three-dimensional graphene composite adsorbent

An adsorbent, graphene technology, applied in the field of chemical materials, can solve the problems of limited adsorption capacity of PPCPs, difficult separation of powder materials, poor recycling effect, etc., to achieve high mechanical strength, strong hydrophilicity, and good catalytic performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] Utilize the method of the embodiment of the present invention to prepare the adsorbent, and carry out adsorption and regeneration detection on the adsorbent, specifically as follows:

[0072] 1. Preparation of adsorbent

[0073] (1) Mix 2 mg / mL graphene oxide dispersion with 0.025 mol / L ferrous sulfate aqueous solution at a volume ratio of 1:1, sonicate for 5 minutes, then adjust the pH of the solution to 10 with ammonia water, after 10 minutes of sonication , heated at 90 degrees Celsius for 12 hours to obtain a three-dimensional graphene / ferric oxide composite.

[0074] (2) The three-dimensional graphene / ferric oxide composite obtained in step (1) is repeatedly washed in high-purity water until the washing water is neutral.

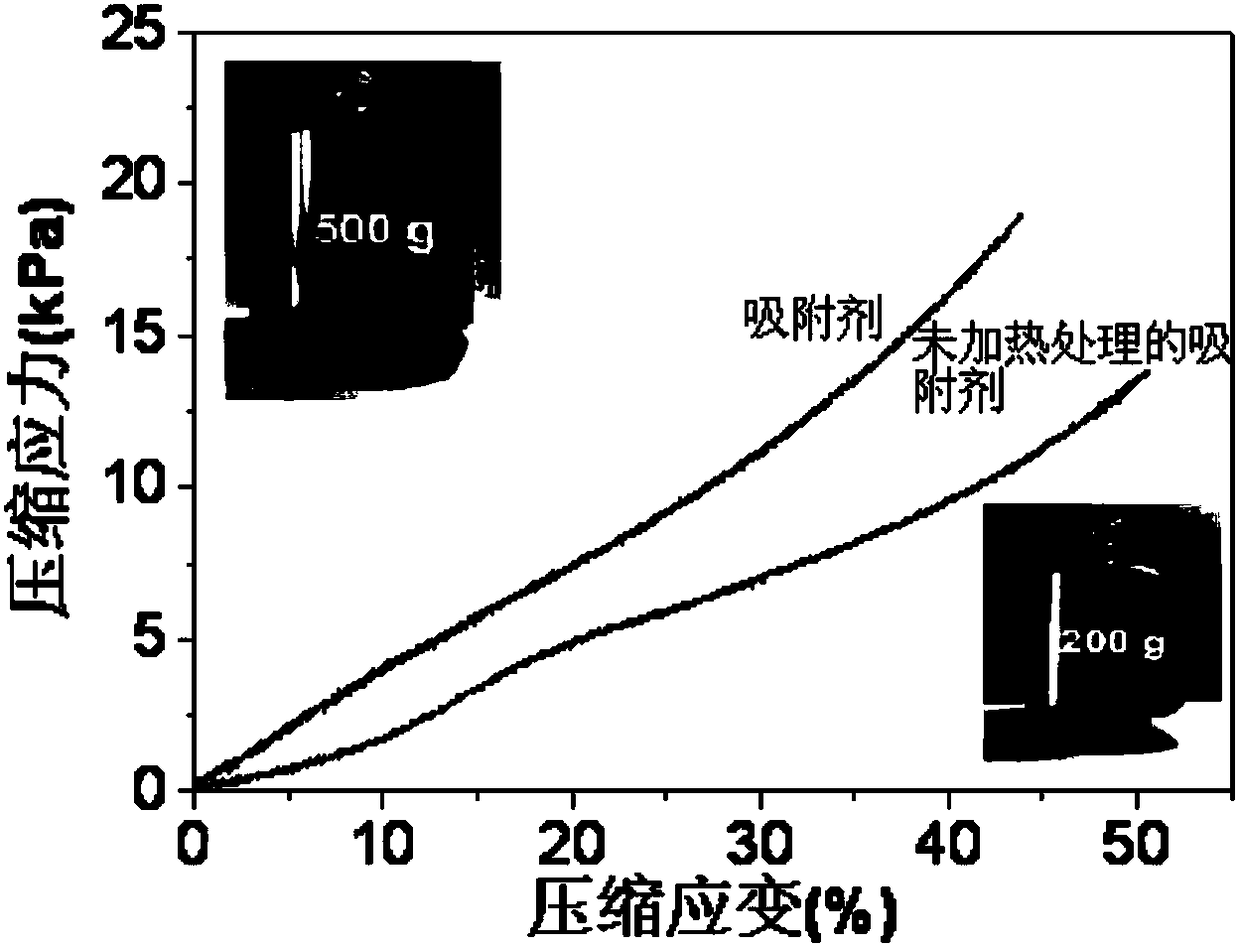

[0075] (3) The three-dimensional graphene / ferric oxide composite after cleaning that step (2) obtains is heated at 50 degrees centigrade for 1 hour to obtain a high-strength adsorbent, and the scanning electron microscope detects the adsorbent, ...

Embodiment 2

[0082] Utilize the method of the embodiment of the present invention to prepare the adsorbent, and carry out adsorption and regeneration detection on the adsorbent, specifically as follows:

[0083] 1. Preparation of adsorbent

[0084] (1) Mix 2 mg / mL graphene oxide dispersion with 0.05 mol / L ferrous sulfate aqueous solution at a volume ratio of 1:1, sonicate for 5 minutes, then adjust the pH of the solution to 11 with ammonia water, and after 10 minutes of sonication , heated at 80 degrees Celsius for 6 hours to obtain a three-dimensional graphene / ferric oxide composite.

[0085] (2) Repeatedly washing the three-dimensional graphene / ferric oxide composite obtained in step (1) in high-purity water until the washing water is neutral.

[0086] (3) heating the three-dimensional graphene / ferric oxide composite obtained in step (2) at 40 degrees Celsius for 1.5 hours to obtain a high-strength adsorbent, which has good hydrophilicity and significantly improved mechanical properties...

Embodiment 3

[0093] 1. Preparation of adsorbent

[0094] (1) Mix 2 mg / mL graphene oxide dispersion with 0.1 mol / L ferrous sulfate aqueous solution at a volume ratio of 1:1, sonicate for 5 minutes, then adjust the pH of the solution to 10 with ammonia water, after 10 minutes of sonication , heated at 70 degrees Celsius for 8 hours to obtain a three-dimensional graphene / ferric oxide composite.

[0095] (2) The three-dimensional graphene / ferric oxide composite obtained in step (1) is repeatedly washed in high-purity water until the washing water is neutral.

[0096] (3) heating the three-dimensional graphene / ferric oxide composite obtained in step (2) at 30 degrees Celsius for 2 hours to obtain a high-strength adsorbent, which has good hydrophilicity and significantly improved mechanical properties.

[0097] 2. Adsorption effect experiment and results

[0098] 5 mg of the prepared adsorbent was put into 0.2 mmol / L 15 mL PPCPs solution, and shaken at 150 rpm for 72 hours. The concentration ...

PUM

| Property | Measurement | Unit |

|---|---|---|

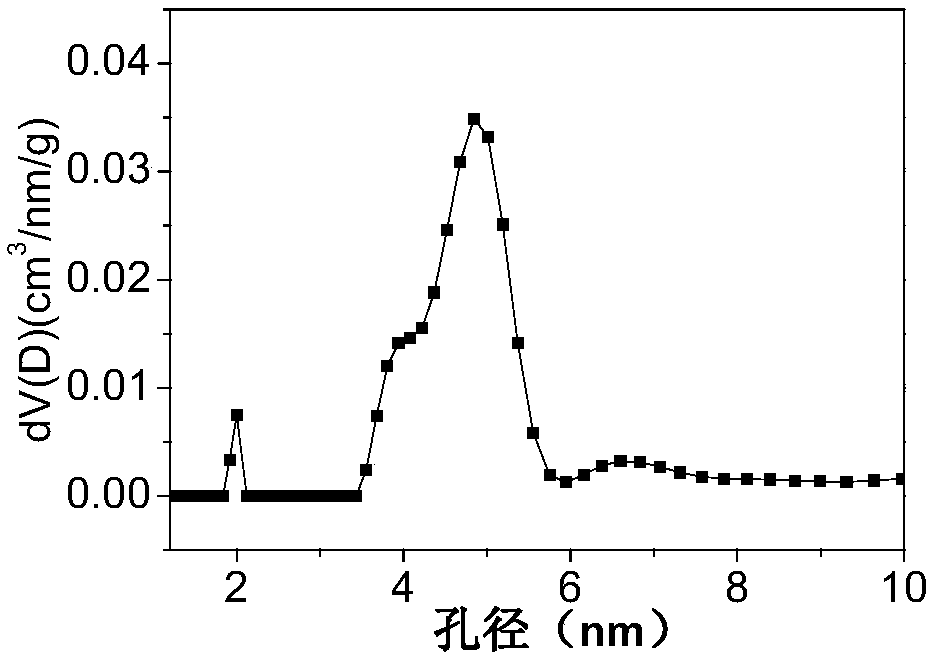

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com