Constant-tension wire conveying device and tension measurement method

A technology of constant tension and force measurement, which is applied in electric processing equipment, metal processing equipment, electrode manufacturing, etc., and can solve problems such as inability to accurately control the tension of the electrode wire, poor electrode wire tension, and short service life of the electrode wire.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

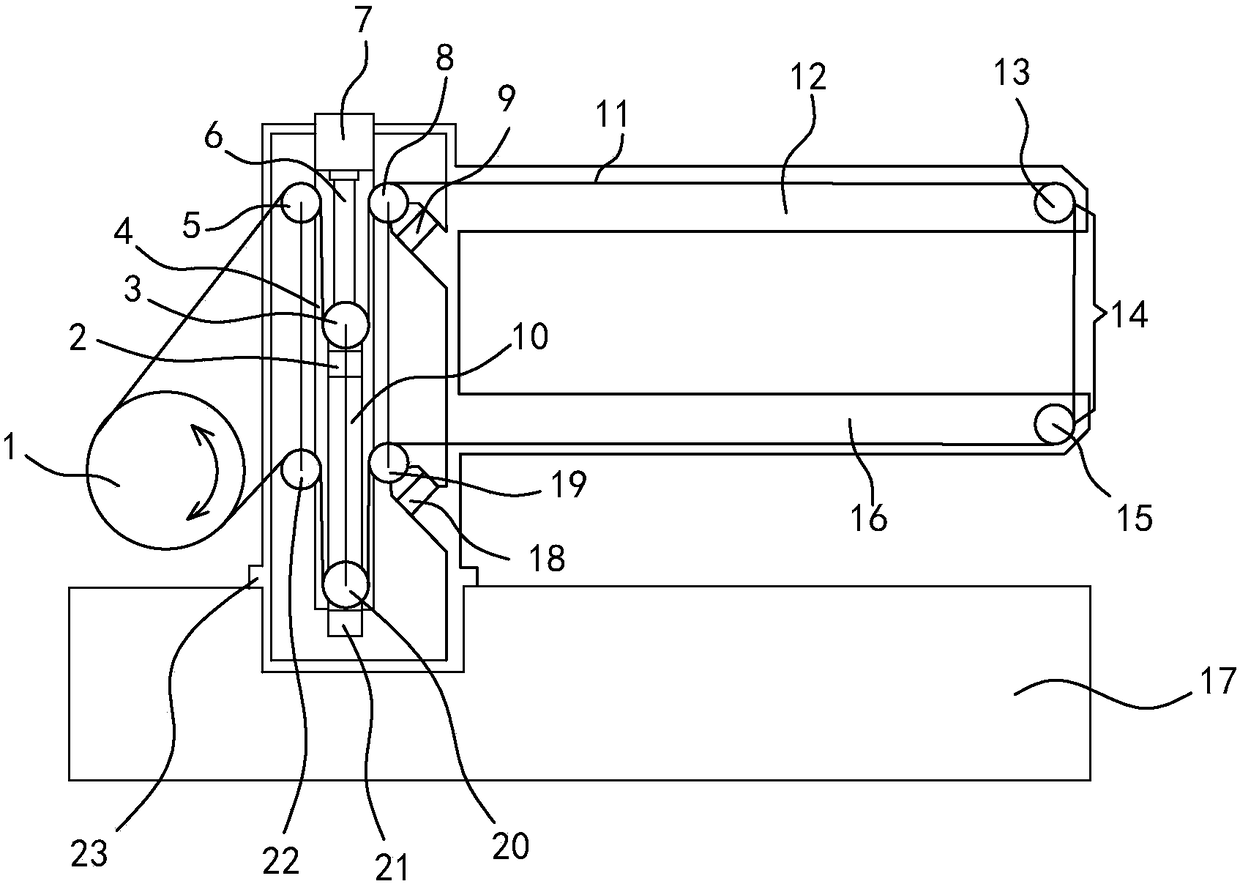

[0057] as attached figure 1 As shown, the wire storage drum 1 is fixed on the bed 17, the column 23 is vertically fixed on the plane of the bed 17, and the upper thread frame arm 12 and the lower thread frame arm 16 are fixedly installed on the upper and lower parts of the column 23 respectively horizontally. positional relationship such as figure 1 shown. The upper guide wheel 13 is rotatably supported on the front portion of the upper thread stand arm 12 , and the lower guide wheel 15 is rotatably supported on the front portion of the lower thread stand arm 16 . The upper row of wire wheels 5 and the lower row of wire wheels 22, which are used to neatly arrange and wrap the electrode wires 11 in the wire storage drum 1, are all rotatably supported on the column 23, and are respectively located on the left side of the single-axis industrial manipulator 4, that is, farther away from the wire storage drum 1. near side. The single-axis industrial manipulator 4 is vertically i...

Embodiment 2

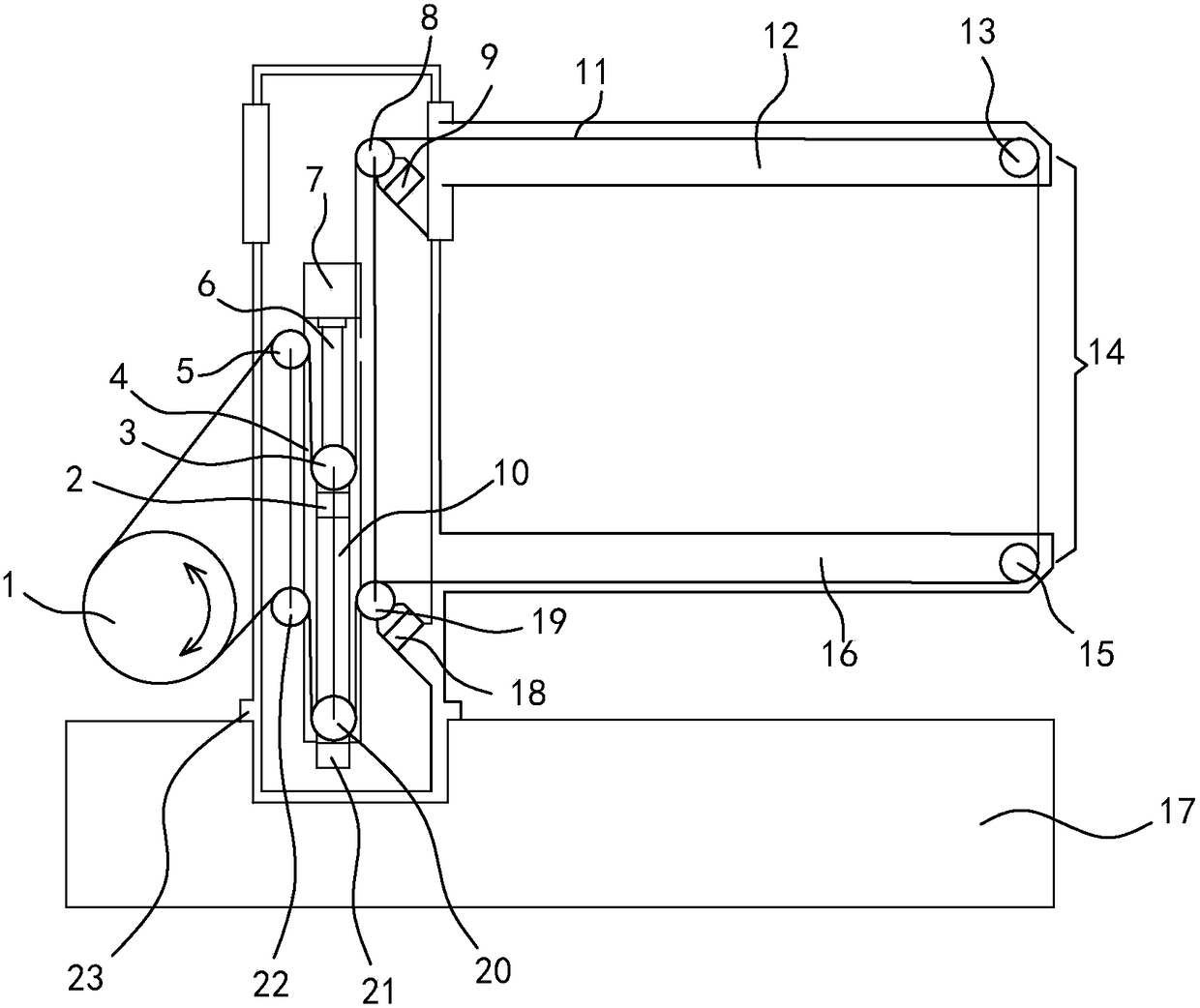

[0062] The difference between this embodiment and Embodiment 1 is that in this embodiment, in order to meet the requirements of cutting and processing workpieces with different thicknesses, the upper wire frame arm 12 can move vertically up and down along the column 23 according to the height of the workpiece, and then move The upper thread stand arm 12 is locked and fixed on the column 23 . The upper guide wheel 13 is rotatably supported on the front part of the upper wire rack arm 12; the second connection surface of the upper load cell 9 is fixed on the right inner side of the upper wire rack arm 12 which is slidingly combined with the column 23, and On the small inclined surface that protrudes at an angle of 45 degrees from the horizontal plane; after the upper wire frame arm 12 is positioned and locked, the axle of the upper force measuring wheel 8 is parallel to the plane of the bed 17, and is still on the same plane as the axle of the lower force measuring wheel 19 paral...

Embodiment 3

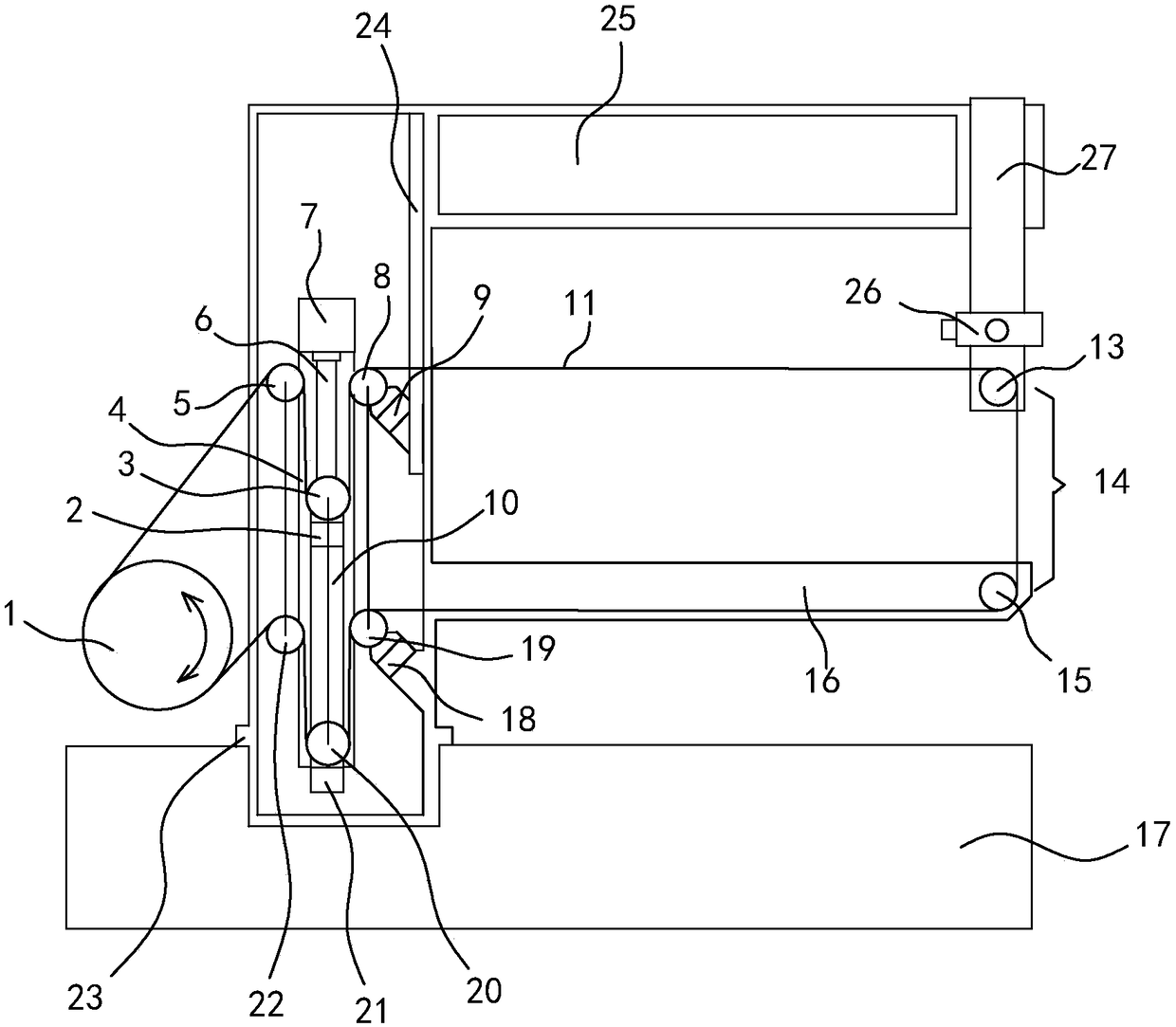

[0064] The difference between this embodiment and Embodiment 1 is that the traditional C-shaped wire frame 25 integrates the upper wire frame arm 12 and the column 23, and there is a wire frame at the front of the C-shaped wire frame 25 that can be used as an upper, The Z-axis 27 of lower lifting, the U-V carriage 26 that a cutting small taper workpiece is fixed below the Z-axis 27, and the upper guide wheel 13 is fixed on the lower carriage of the U-V carriage 26. In this embodiment, the second connection surface of the upper load cell 9 is fixed on a small inclined surface at an angle of 45 degrees to the horizontal plane on the slider of the lifting guide rail assembly 24; the lifting guide rail assembly 24 is fixed on the C-shaped wire frame On the right inner side of the vertical part of the vertical part, the lifting guide rail assembly 24 is synchronously lifted with the Z axis 27, so that the electrode wire between the upper guide wheel 13 and the upper force measuring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com