Thermal deformation control device of multiple-degree-of-freedom spatial structure

A space structure and control device technology, applied in auxiliary devices, manufacturing tools, auxiliary welding equipment, etc., can solve the problems of difficult deformation control, failure to meet process index requirements, increase manufacturing costs, etc., to improve welding efficiency and quality, Avoids incomplete penetration defects and has a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

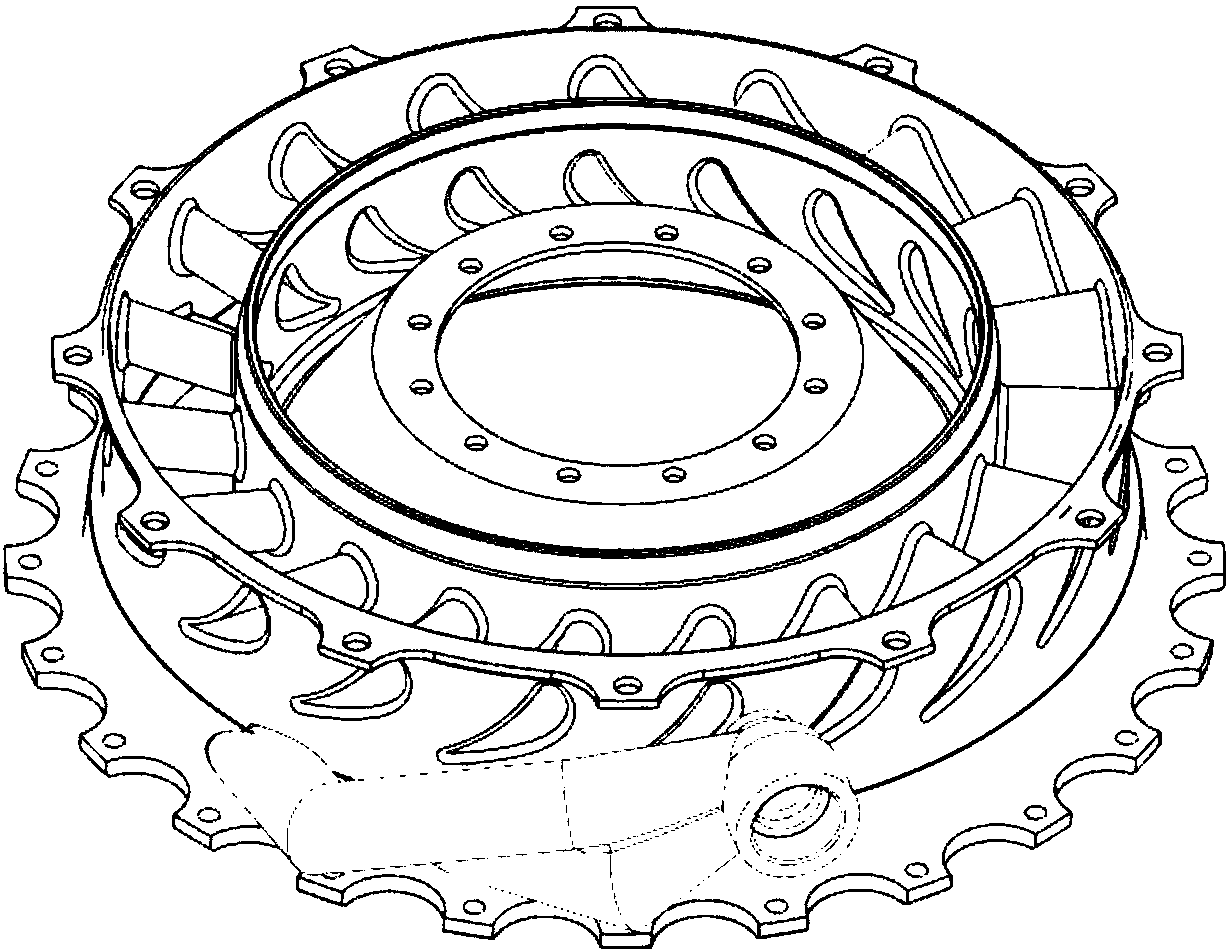

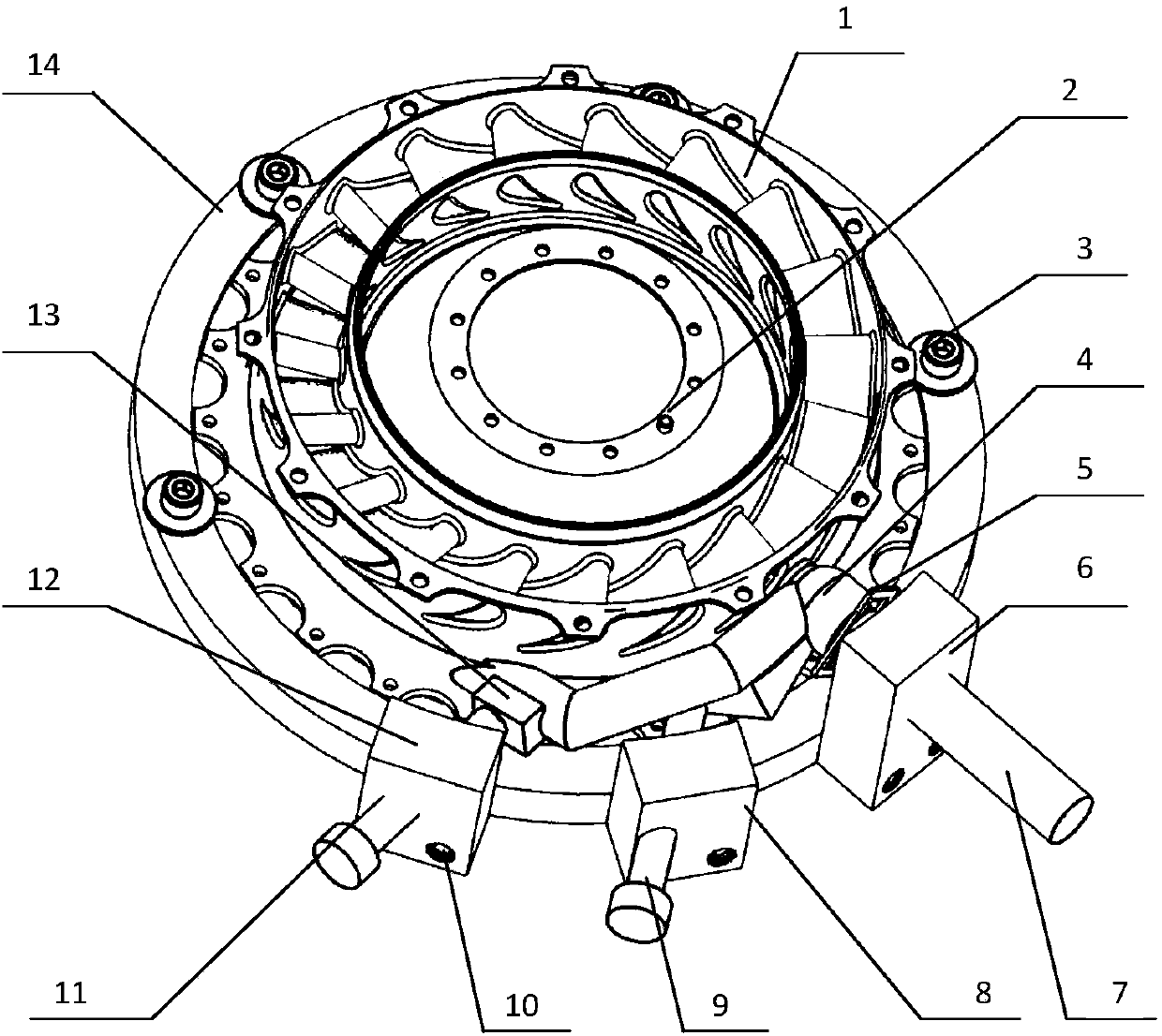

[0021] Such as figure 2 As shown, the present invention provides a thermal deformation control device with a multi-degree-of-freedom space structure, which includes an angular positioning pin 2, a compression screw 3, a pressure relief gasket 5, a first positioning block 6, a positioning screw 7, a Two positioning blocks 8, the first positioning compression screw 9, connecting screw 10, the second positioning compression screw 11, the third positioning block 12, auxiliary profiling compression block 13 and base 14, the peripheral equipment is a guide to be welded 1 and starting nozzle 4;

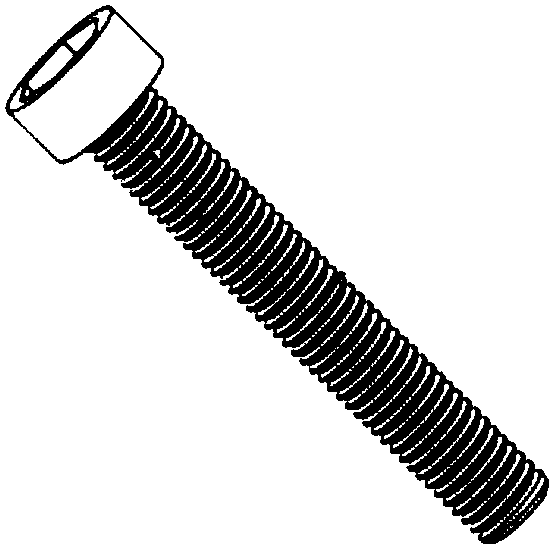

[0022] as attached image 3 As shown, the first positioning compression screw 9 and the second positioning compression screw 11 have the same structure, and both have a hexagonal inner end for adjusting the compression force with a hexagonal wrench.

[0023] as attached Figure 4 As shown, the diameter of the positioning screw 7 is larger than that of the first positioning compression sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com