Rubber powder modified asphalt mixture and preparation method thereof

A technology of asphalt mixture and modified asphalt, which is applied in the field of modified asphalt, can solve the problems that cannot accurately reflect the mechanical properties of asphalt mixture, and can not better correspond to the technical performance of asphalt pavement, so as to promote sustainable development and improve the road surface The effect of using performance and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

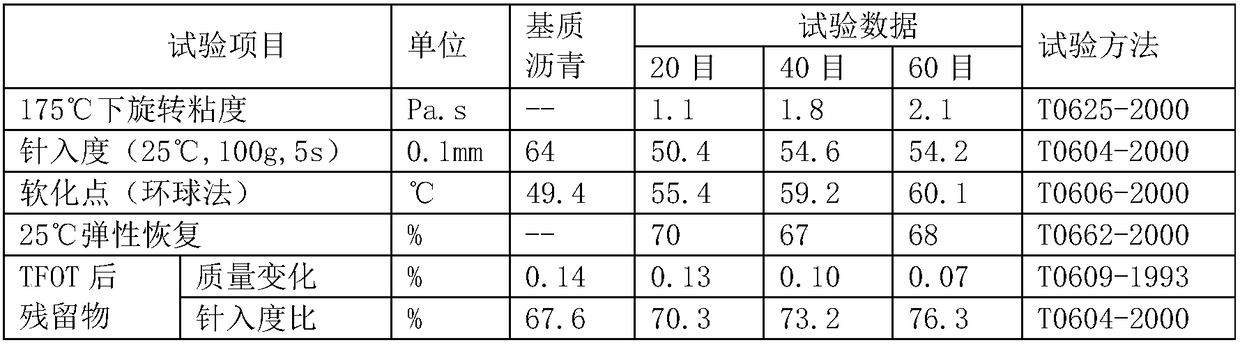

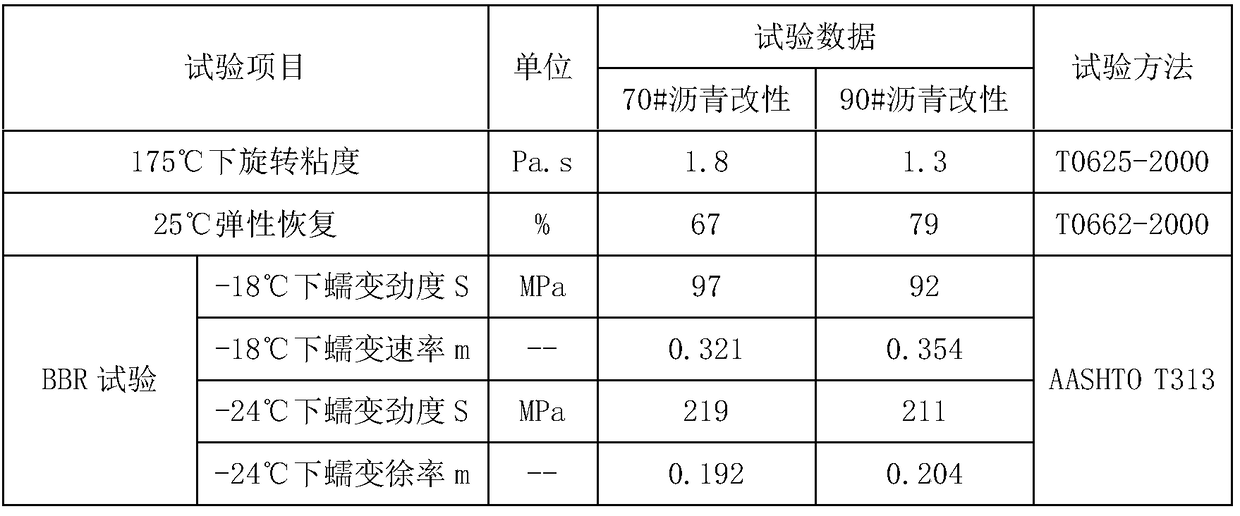

[0036] In the preparation method of rubber powder modified asphalt of the present invention, when the base asphalt is heated to the required temperature, the high-shear dispersing and emulsifying machine is started, and the rubber powder is evenly added while shearing, and stirred for a specified time and paying attention to the temperature of the stirring process The rubber powder modified asphalt samples can be prepared. The high-shear dispersing emulsifier used in the embodiments of the present invention is an open laboratory high-shear mixing emulsifier produced by Shanghai Shanggui Machinery Electronics Co., Ltd., and its principle is to shred and disperse rubber powder by high-speed shearing. Form rubber powder asphalt in asphalt. It can truly simulate the actual situation of producing rubber powder asphalt materials on the construction site. The agitator of the agitator used in the embodiment of the present invention is a screw agitator.

[0037] The preparation metho...

experiment example

[0047] When GTM forms the test piece, it effectively simulates the final compaction state of the asphalt mixture under the action of road traffic load: that is, the asphalt mixture test piece is continuously kneaded, sheared and compacted under the specified mechanical rotation angle and set vertical pressure , until the equilibrium state (refers to the density change rate of 0.016g / cm per 100 rotations of the specimen 3 ). During the forming process of the test piece, GTM can automatically collect the stress and strain data of the test piece, and display the change curve of the shear strength. The strain of the specimen is characterized by the size of the machine angle, and the shear strength SG is obtained by reasoning and converting the roller pressure.

[0048] The purpose of the GTM forming test is to simulate the final compaction state of the asphalt mixture under the action of road traffic load, that is, the equilibrium state, and test and analyze the shear strength an...

Embodiment 1

[0071] This embodiment provides a method for preparing rubber powder modified asphalt, comprising the following steps:

[0072] 1) Processing of raw materials: drying the rubber powder at a temperature of 105°C; dehydrating the base asphalt for later use;

[0073] 2) Miscibility reaction: heat the dehydrated base asphalt in step 1) to 180°C, then add the dried rubber powder in step 1) into the base asphalt, stir and swell for 42 minutes to obtain a mixed solution; mix the rubber powder When adding to the base asphalt, it must be added while stirring to prevent splashing and hurting people during the stirring process; when starting the mixer to stir, the stirring speed should be slow to fast, starting from 260-300r / min and stirring within 20 minutes The speed increased to 1000r / min, and finally stabilized at 1000r / min and stirred for 15 minutes, and the stirring temperature was controlled at 190°C to 210°C;

[0074] 3) Finished product: pump the mixed liquid in step 2) into th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com