Light-cured resin for 3D (Three-dimensional) printing

A light-curing resin and 3D printing technology, applied in the direction of additive processing, etc., can solve problems such as affecting accuracy and part deformation, and achieve the effects of improving molding accuracy, improving mechanical properties, and reducing shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

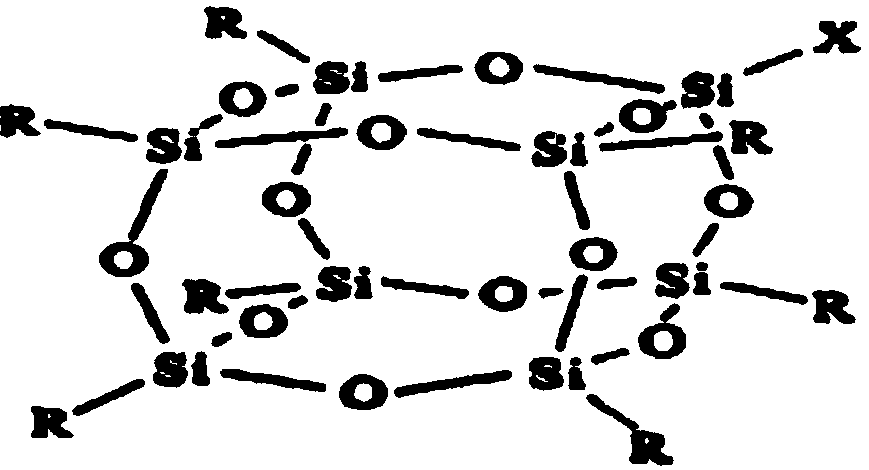

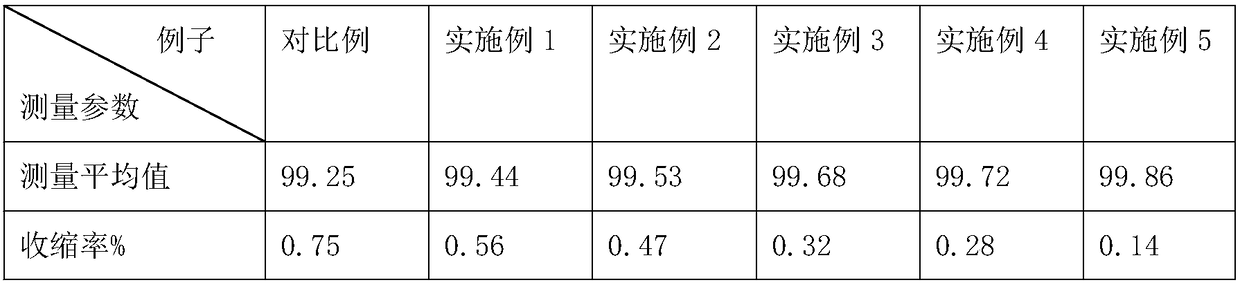

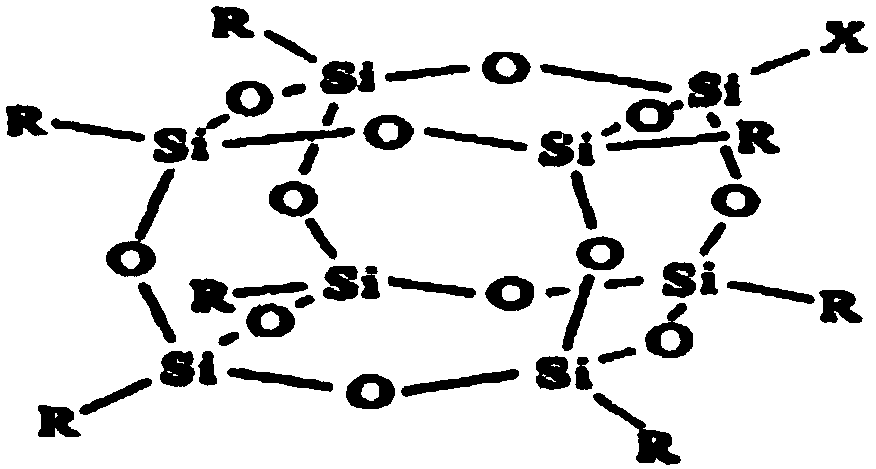

[0016] A 3D printing photocurable resin, wherein the mass percentages of each component are: 30% bisphenol A type E-51 epoxy resin, 20% alicyclic epoxy resin, 5% 1,6-hexanediol diacrylic acid Esters, 5% trimethylolpropane triacrylate, 20% 3-hydroxymethyl-1-oxetane, 10% 2-hydroxymethyloxetane, 5% benzoin dimethyl ether, 5 % Rigid Polysiloxane.

Embodiment 2

[0018] A 3D printing photocurable resin, wherein the mass percentages of each component are: 30% bisphenol A type E-51 epoxy resin, 30% alicyclic epoxy resin, 10% 1,6-hexanediol diacrylic acid Esters, 5% trimethylolpropane triacrylate, 6% 3-hydroxymethyl-1-oxetane, 6% 2-hydroxymethyloxetane, 5% benzoin dimethyl ether, 8 % Rigid Polysiloxane.

Embodiment 3

[0020] A 3D printing photocurable resin, wherein the mass percentages of each component are: 40% bisphenol A type E-51 epoxy resin, 30% alicyclic epoxy resin, 5% 1,6-hexanediol diacrylic acid Esters, 5% trimethylolpropane triacrylate, 5% 3-hydroxymethyl-1-oxetane, 5% 2-hydroxymethyloxetane, 5% benzoin dimethyl ether, 5% % Rigid Polysiloxane.

PUM

| Property | Measurement | Unit |

|---|---|---|

| shrinkage | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com