A method for preparing caramel malt with high caramel aroma and beer

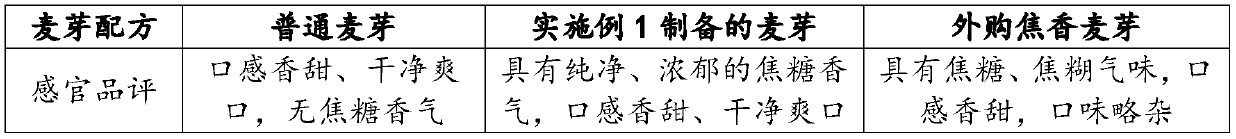

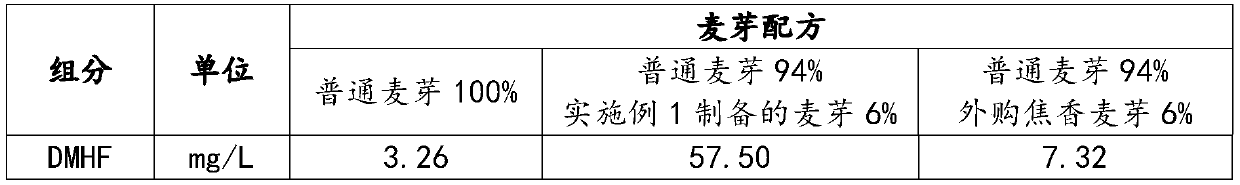

A caramel malt and aroma technology, applied in the field of caramel malt preparation, can solve the problems of mixed aroma and affecting the purity of caramel aroma, and achieve the effect of increasing concentration, pure and strong aroma, and high DMHF content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The embodiment of the present invention provides a method for preparing caramel-flavored malt with high caramel aroma, which includes the steps of wheat selection, raw material pretreatment, wheat soaking, germination, green malt mashing, roasting and root removal. The specific steps are as follows:

[0033] (1) Wheat selection: select barley with a protein content between 10% and 11% and a germination rate above 97% as raw materials. In this step, it should be noted that the protein content of barley selected in this embodiment is the optimum range. If the protein content is too low, the enzymatic reaction will generate a low content of amino compounds, which will affect the efficiency of the Maillard reaction; if the protein content If the temperature is too high, the protein and starch granules will be tightly wrapped, and the malt content will not be easily decomposed, and the long dissolution time will affect the efficiency of malt preparation. In addition, when ch...

Embodiment 1

[0055] 1. High caramel aroma caramel malt-Aomai Compass

[0056] (1) Wheat selection: select the Australian wheat Compass with a protein content of 10.8% (between 10% and 11%) as raw material, the barley grains are plump, and the barley germination rate is 99% (above 97%);

[0057] (2) Raw material pretreatment: clean the barley, remove the straw, bag rope, wood, nails, screws, metal wires, stones, miscellaneous wheat grains, broken barley grains, etc.; Uniformly sized barley with a length of 2.5mm-2.8mm;

[0058] (3) Wheat soaking: add the wheat soaking water into the wheat soaking tank, then feed the barley into the wheat soaking tank, and a small part of the floating wheat and impurities floating on the liquid surface are collected through the collection port to complete the floating wheat operation; After the floating wheat was finished, the water quality was changed, and the wheat was soaked at a water temperature of 17°C using a multi-stage soaking and water-cutting met...

Embodiment 2

[0077] 1. High caramel aroma caramel malt-Farmer Irina

[0078] (1) Wheat selection: select the French wheat Irina with a protein content of 10.2% (between 10% and 11%) as a raw material, the barley grains are plump, and the barley germination rate is 97% (above 97%);

[0079] (2) Raw material pretreatment: clean the barley, remove the straw, bag rope, wood, nails, screws, metal wires, stones, miscellaneous wheat grains, broken barley grains, etc.; Uniformly sized barley with a length of 2.5mm-2.8mm;

[0080](3) Wheat soaking: add the wheat soaking water into the wheat soaking tank, then feed the barley into the wheat soaking tank, and a small part of the floating wheat and impurities floating on the liquid surface are collected through the collection port to complete the floating wheat operation; After the floating wheat was finished, the water quality was changed, and the wheat was soaked at a water temperature of 16°C using a multi-stage soaking and water-cutting method of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com