Method of industrial quick production and preparation of glucosyl stevioside mixture

A technology based on stevioside and steviol glycoside, which is applied in the field of rapid industrial production and preparation of glucosyl stevioside mixture, which can solve the problems of cumbersome steps, large damage to iron-containing equipment, and many impurities, and achieve mild enzymatic reaction conditions and reduce production costs , Reduce the effect of process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

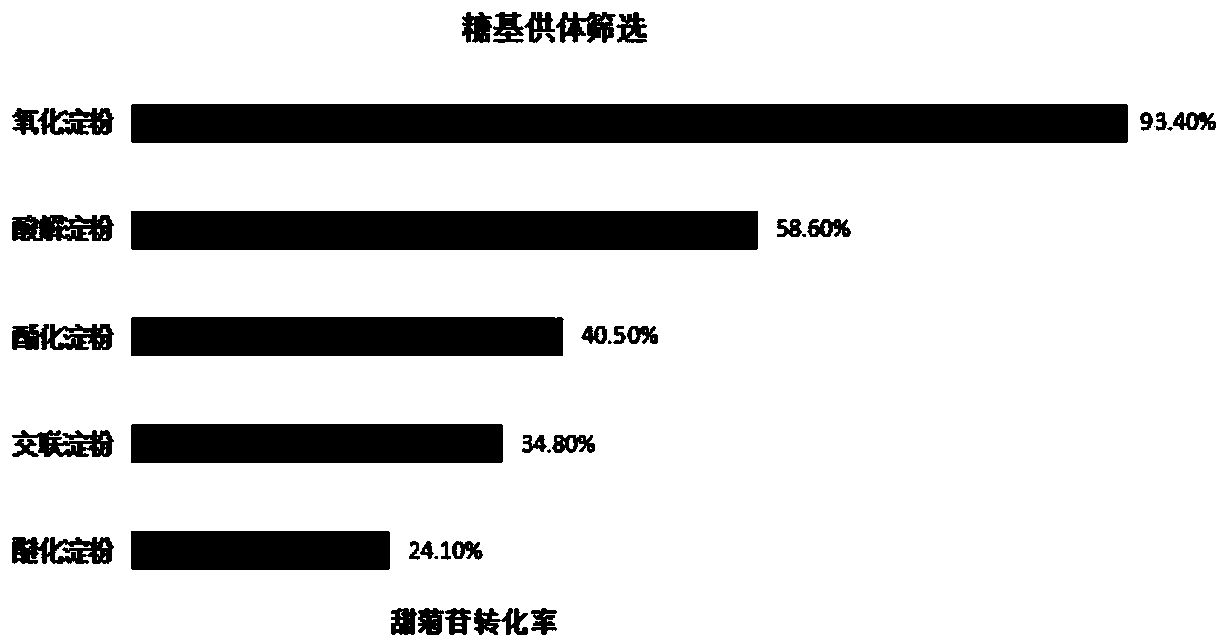

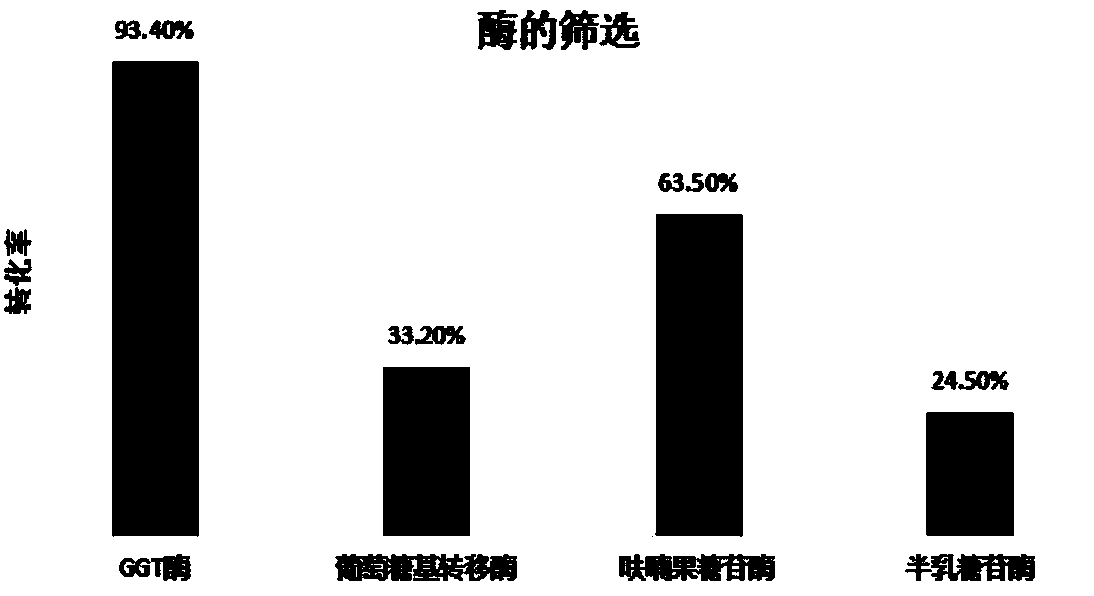

Method used

Image

Examples

Embodiment 1

[0035] (1) Heat 1000ml of tap water to 55°C, and add 100 grams of oxidized starch at a constant speed under stirring to make it fully dissolve into a transparent liquid; Uniform transparent mixture of oxidized starch and steviol glycosides.

[0036] (2) Cool the uniformly dissolved oxidized starch and steviol glycoside mixture to 40°C.

[0037](3) Add 5 grams of CGTase (manufactured by Novozymes) to the uniformly dissolved oxidized starch and steviol glycoside mixture, adjust the pH value to 3.5 with hydrochloric acid, and carry out glycosylation reaction for 7 hours under stirring.

[0038] (4) Heat the above glycosylation reaction product to 95° C. and keep it for 10 minutes to inactivate CGT enzyme activity and end the glycosylation reaction.

[0039] (5) Add 3 grams of activated carbon powder, incubate at 85° C. for 20 minutes for decolorization and deodorization; filter to remove activated carbon powder and CGT enzyme.

[0040] (6) Concentrate the filtrate under reduced...

Embodiment 2

[0042] (1) Heat 2000ml of tap water to 100°C, and add 150 grams of oxidized starch at a constant speed under stirring to make it fully dissolve into a transparent liquid; Uniform transparent mixture of oxidized starch and steviol glycosides.

[0043] (2) Cool the uniformly dissolved oxidized starch and steviol glycoside mixture to 55°C.

[0044] (3) Add 15 grams of CGTase (manufactured by Novozymes) to the uniformly dissolved oxidized starch and steviol glycoside mixture, adjust the pH value to 5 with hydrochloric acid, and carry out the glycosylation reaction for 12 hours under stirring.

[0045] (4) Heat the above glycosylation reaction product to 100° C. for 20 minutes to inactivate CGT enzyme activity and end the glycosylation reaction.

[0046] (5) Add 15 grams of activated carbon powder, incubate at 100° C. for 40 minutes for decolorization and deodorization; filter to remove activated carbon powder and CGT enzyme.

[0047] (6) Concentrate the filtrate under reduced pr...

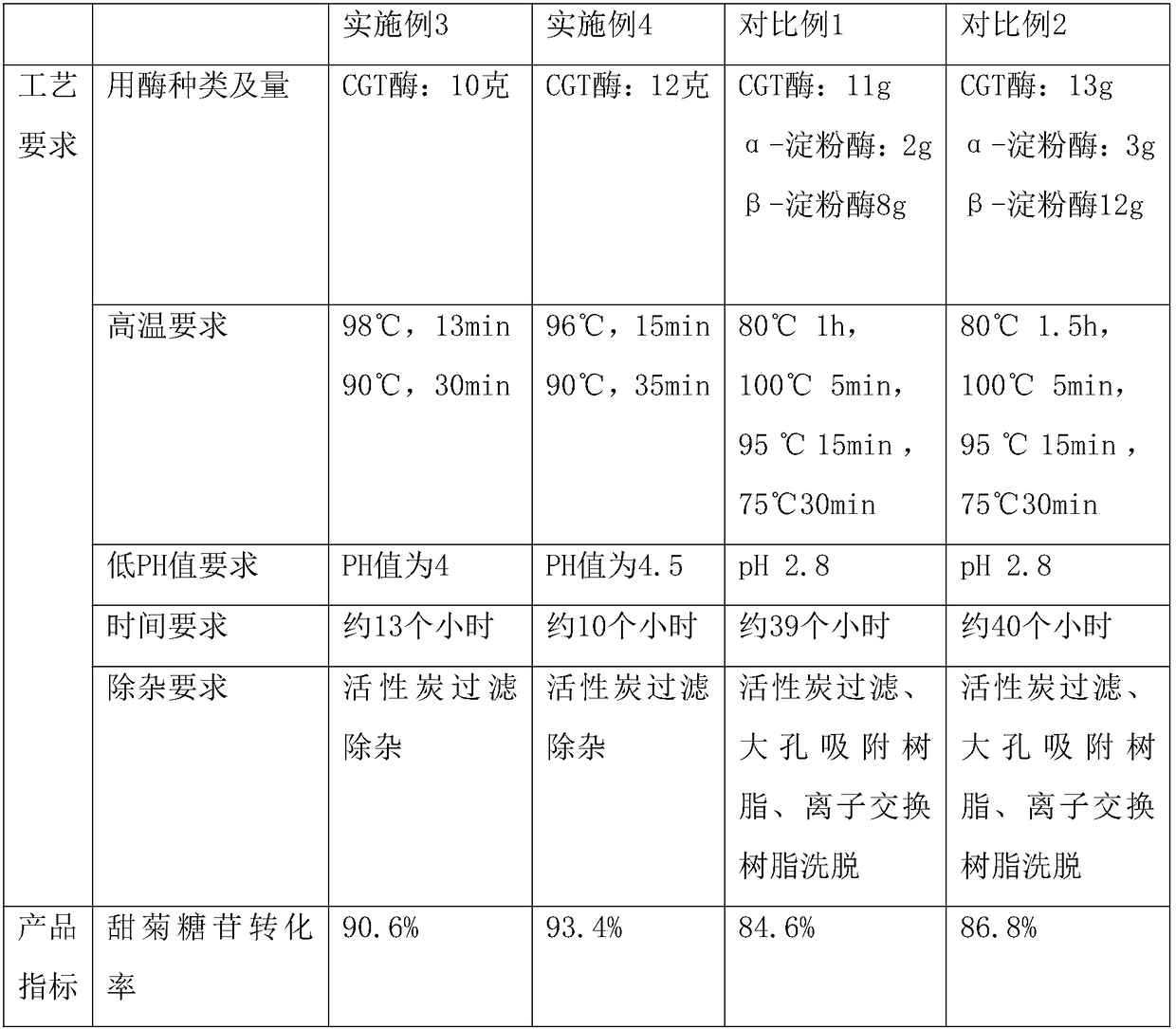

Embodiment 3

[0049] (1) Heat 1600ml of purified water to 60°C, and add 130 grams of oxidized starch at a constant speed under stirring to make it fully dissolve into a transparent liquid; then add 100 grams of 95% steviol glycoside at a constant speed to the transparent liquid under stirring, Generate a uniform transparent mixture of oxidized starch and steviol glycosides.

[0050] (2) Cool the uniformly dissolved oxidized starch and steviol glycoside mixture to 45°C.

[0051] (3) Add 10 g of CGTase (manufactured by Novozymes) to the uniformly dissolved oxidized starch and steviol glycoside mixture, adjust the pH value to 4 with hydrochloric acid, and carry out glycosylation reaction for 11 hours under stirring.

[0052] (4) Heat the above glycosylation reaction product to 98° C. and keep it for 13 minutes to inactivate CGT enzyme activity and end the glycosylation reaction.

[0053] (5) Add 5 grams of activated carbon powder, incubate at 90° C. for 30 minutes for decolorization and deodo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com