Preparation method of molybdenum-niobium target blank

A manufacturing method and technology of target blanks, which are applied in the field of target sputtering, can solve the problems that the performance of molybdenum-niobium target blanks needs to be improved, and achieve the effect of uniform microstructure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] It can be known from the background technology that the performance of the molybdenum-niobium target blank formed by the prior art needs to be improved. The reasons are:

[0036] At present, most of the domestic molybdenum-niobium alloy sintering process stays in the sample experiment stage, and industrial production has not yet been realized. However, when large-scale production of molybdenum-niobium alloys, the current formed molybdenum-niobium alloys have high hardness and are prone to cracks, which makes it difficult for the formed molybdenum-niobium alloys to meet the requirements of semiconductor, solar, LCD and other industries. Therefore, there is an urgent need to provide a sintering process for large-scale production of molybdenum-niobium alloys to ensure the formation of large-scale samples, so that the formed molybdenum-niobium target blanks can meet the performance requirements of sputtering targets.

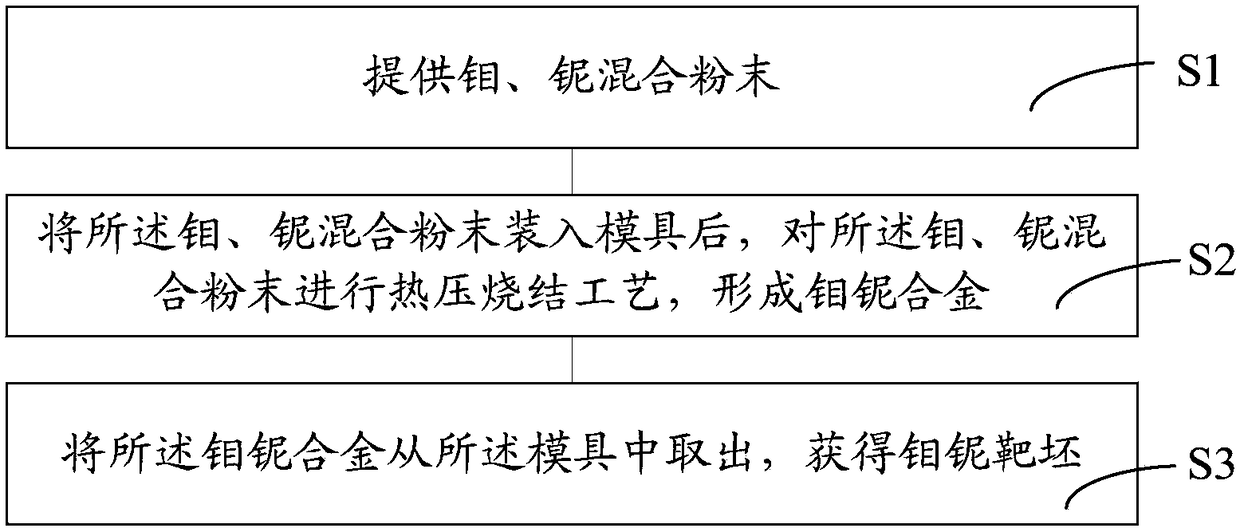

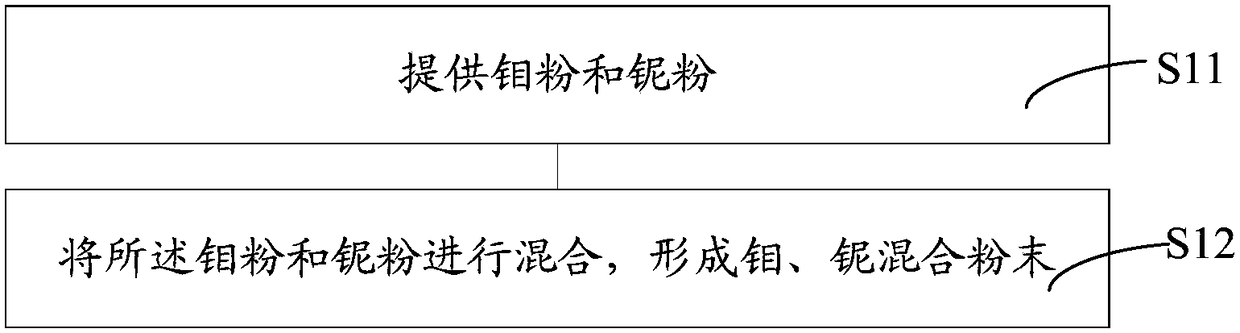

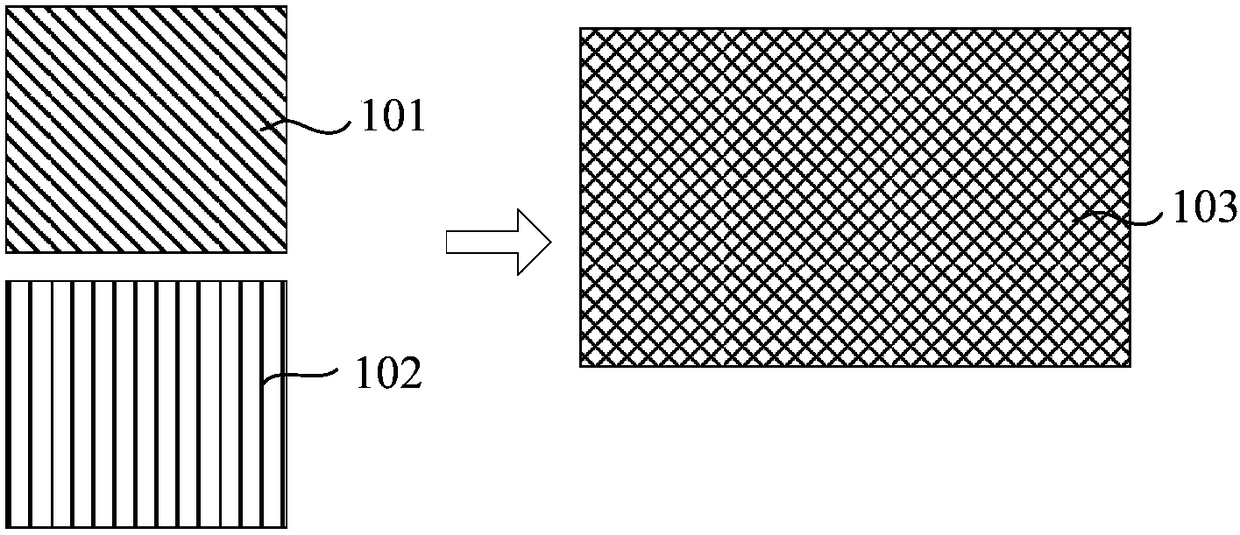

[0037] In order to solve the above problems, the present in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface smoothness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com