Preparation method of ni-salen complex and ni-salen complex

A technology of complexes and ligands, applied in the direction of electrolytic components, electrolytic organic production, electrolytic process, etc., can solve problems such as troubles, and achieve the effect of simple steps and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

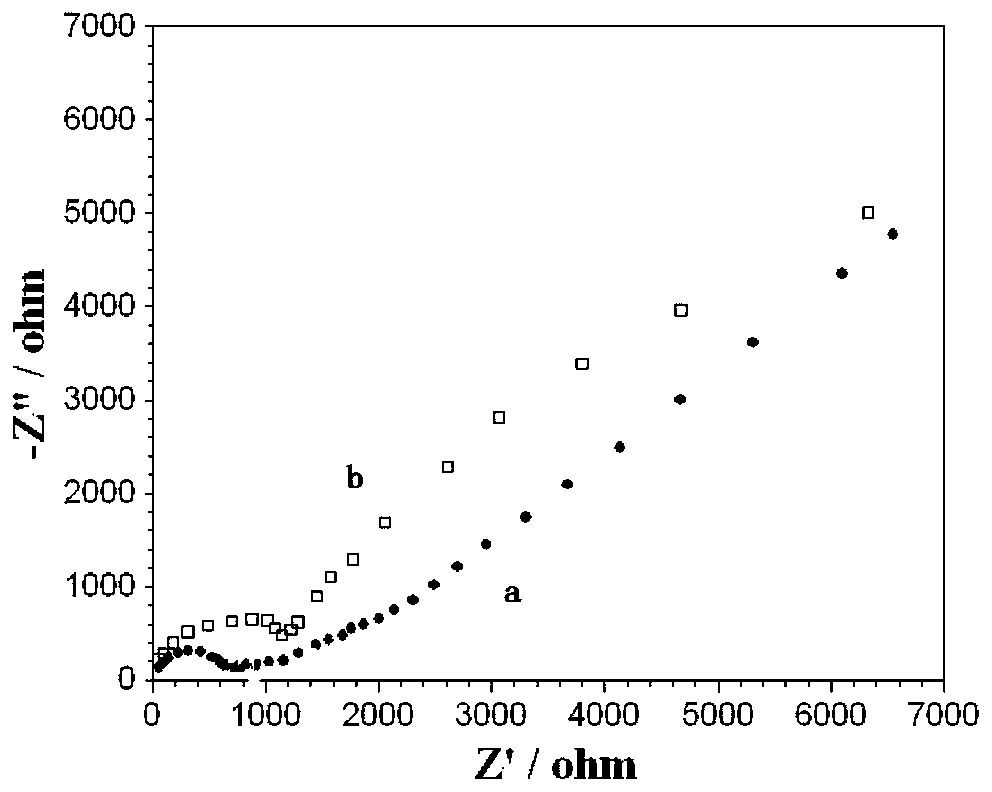

[0023] The invention provides a preparation method of a Ni-Salen complex. After electrodepositing nickel ferricyanide on the surface of a bare electrode, the Salen ligand is modified, and then the modified electrode is electrochemically activated in lye to obtain a Ni-Salen complex. Modified electrodes, Ni-Salen complexes were synthesized on the electrode surface.

[0024] The preparation method provided by the invention uses an electrode to directly electrochemically synthesize the Ni-Salen complex, and proposes a new preparation method of the Ni-Salen complex.

[0025] At the same time, the electrochemical synthesis method proposed in the present invention only needs to perform electrodeposition and surface modification operations, and does not need to perform operations such as building a system, controlling temperature, stirring, and separating. The steps are simple and the operation is convenient.

[0026] The present invention uses a glassy carbon electrode (GCE) for ele...

Embodiment 1

[0041] A preparation method of Ni-Salen complex, comprising:

[0042] S1. Polish the glassy carbon electrode and then ultrasonically clean it to obtain a bare GCE.

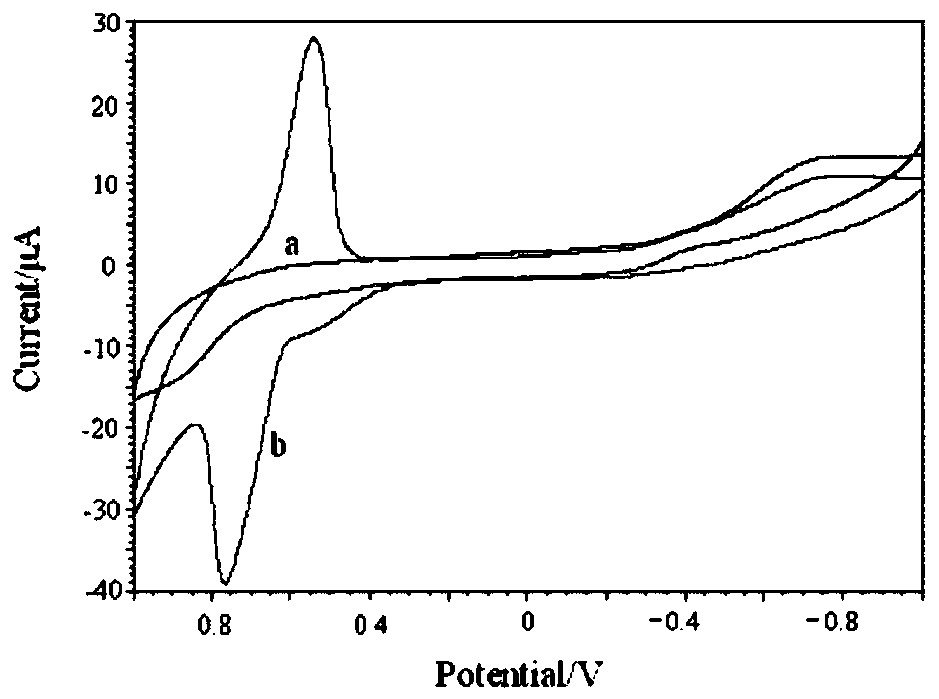

[0043] S2. Put bare GCE into K 3 [Fe(CN) 6 ] and NiAc 2 The concentration is 10mmol / L solution, and the cyclic voltammetry scans 20 times to get NiHCF / GCE.

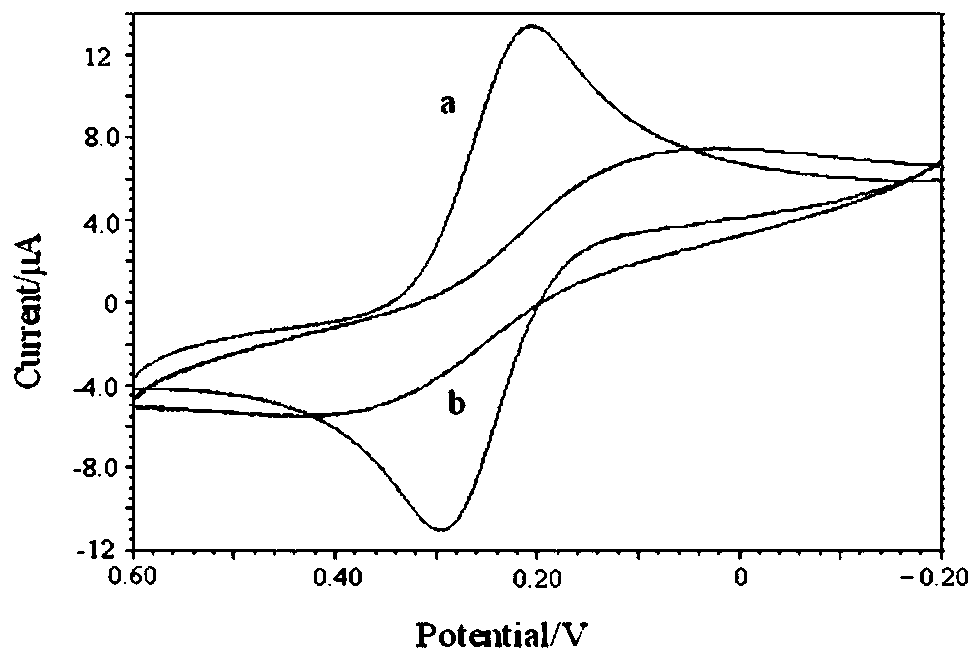

[0044] S3. Drop-coat the Salen ligand solution with a concentration of 10mg / mL on the surface of NiHCF / GCE, put it into 0.01mol / L sodium hydroxide solution after drying, and perform cyclic voltammetry scanning in the potential range of -1 to 1V. Get Salen-Ni / GCE.

Embodiment 2

[0046] A preparation method of Ni-Salen complex, comprising:

[0047] S1. Polish the glassy carbon electrode and then ultrasonically clean it to obtain a bare GCE.

[0048] S2. Put bare GCE into K 3 [Fe(CN) 6 ] and NiAc 2 The concentration is 100mmol / L solution, and the cyclic voltammetry scans 25 times to obtain NiHCF / GCE.

[0049] S3. Drop-coat the Salen ligand solution with a concentration of 10mg / mL on the surface of NiHCF / GCE, put it into 0.01mol / L sodium hydroxide solution after drying, and perform cyclic voltammetry scanning in the potential range of -1 to 1V. Get Salen-Ni / GCE.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com