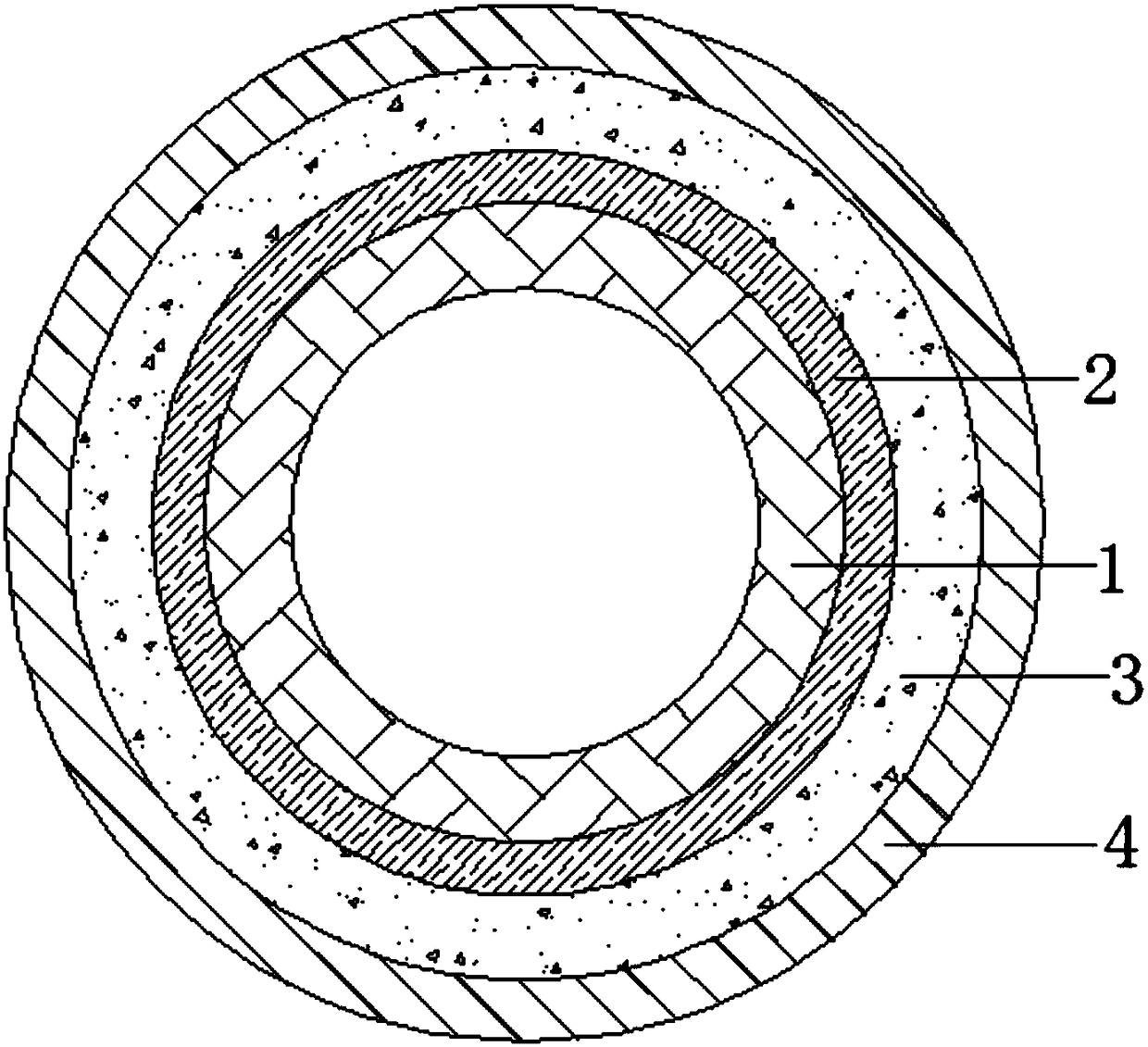

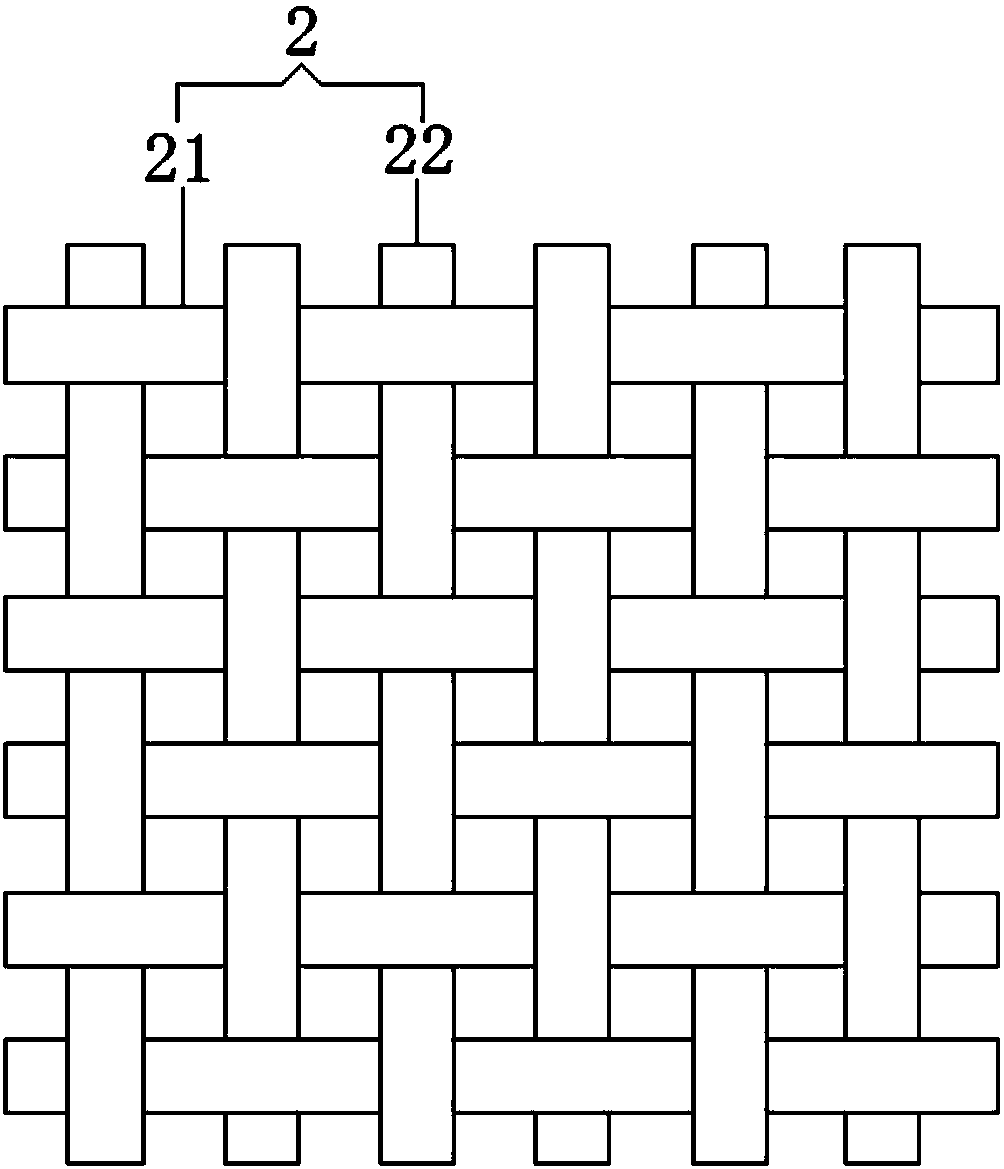

Impact-resistant non-flammable fire-fighting water pipe and manufacturing method thereof

A technology for fire-fighting water pipes and manufacturing methods, which is applied in the direction of hoses, pipes, tubular objects, etc., and can solve the problems of fire-fighting water pipes that are not resistant to high pressure, affect quality stability, and poor integrity, and achieve the purpose of overcoming uneven tensile wall thickness , high production efficiency, the effect of preventing impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The manufacturing method of the impact-resistant and non-flammable fire-fighting water pipe comprises the following steps:

[0036] S1: Weigh the raw materials for preparing the inner tube 1 and the protective layer 3 according to the weight ratio of each raw material. The composition of the inner tube 1 is as follows: EVOH: 93 parts; lubricant 4 parts; heat stabilizer 6.6 parts; drag reducer 3.8 parts; 4.7 parts of accelerator; 1 part of softener and 3 parts of low temperature resistant agent; the composition of the protective layer 3 is as follows: EVOH: 100 parts; 21 parts of polystyrene; 11.3 parts of fireproofing agent; 7.9 parts of carbon black; 7.1 parts of waterproofing agent; 22 parts of polyurethane and 12 parts of microporous calcium silicate;

[0037] S2: Put the raw materials of the inner tube 1 and the protective layer 3 in step S1 into different mixers and stir evenly, the stirring speed is 40 rpm, and the stirring time is 15 minutes;

[0038] S3: Wrap t...

Embodiment 2

[0045] The manufacturing method of the impact-resistant and non-flammable fire-fighting water pipe comprises the following steps:

[0046] S1: Weigh the raw materials for preparing the inner tube 1 and the protective layer 3 according to the weight ratio of each raw material. The composition of the inner tube 1 is as follows: EVOH: 98 parts; lubricant 3.3 parts; heat stabilizer 7 parts; drag reducer 3.7 parts; 3 parts of accelerator; 3 parts of softening agent and 2.3 parts of low temperature resistant agent; the composition of the protective layer 3 is as follows: EVOH: 97 parts; 24 parts of polystyrene; 13 parts of fireproofing agent; 4.5 parts of metal magnesium oxide 7.6 parts of carbon black; 8 parts of waterproofing agent; 24 parts of polyurethane and 13 parts of microporous calcium silicate;

[0047] S2: Put the raw materials of the inner tube 1 and the protective layer 3 in step S1 into different mixers and stir evenly, the stirring speed is 60 rpm, and the stirring ti...

Embodiment 3

[0055] The manufacturing method of the impact-resistant and non-flammable fire-fighting water pipe comprises the following steps:

[0056] S1: Weigh the raw materials for preparing the inner tube 1 and the protective layer 3 according to the weight ratio of each raw material. The composition of the inner tube 1 is as follows: EVOH: 95 parts; lubricant 3 parts; heat stabilizer 7 parts; drag reducer 3.5 parts; 4 parts of accelerator; 2 parts of softening agent and 2.5 parts of low temperature resistant agent; the composition of the protective layer 3 is as follows: EVOH: 95 parts; 22.5 parts of polystyrene; 12 parts of fireproofing agent; 7.5 parts of carbon black; 7.5 parts of waterproofing agent; 25 parts of polyurethane and 12.5 parts of microporous calcium silicate;

[0057] S2: Put the raw materials of the inner tube 1 and the protective layer 3 in step S1 into different mixers and stir evenly, the stirring speed is 50 rpm, and the stirring time is 20 minutes;

[0058] S3:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com