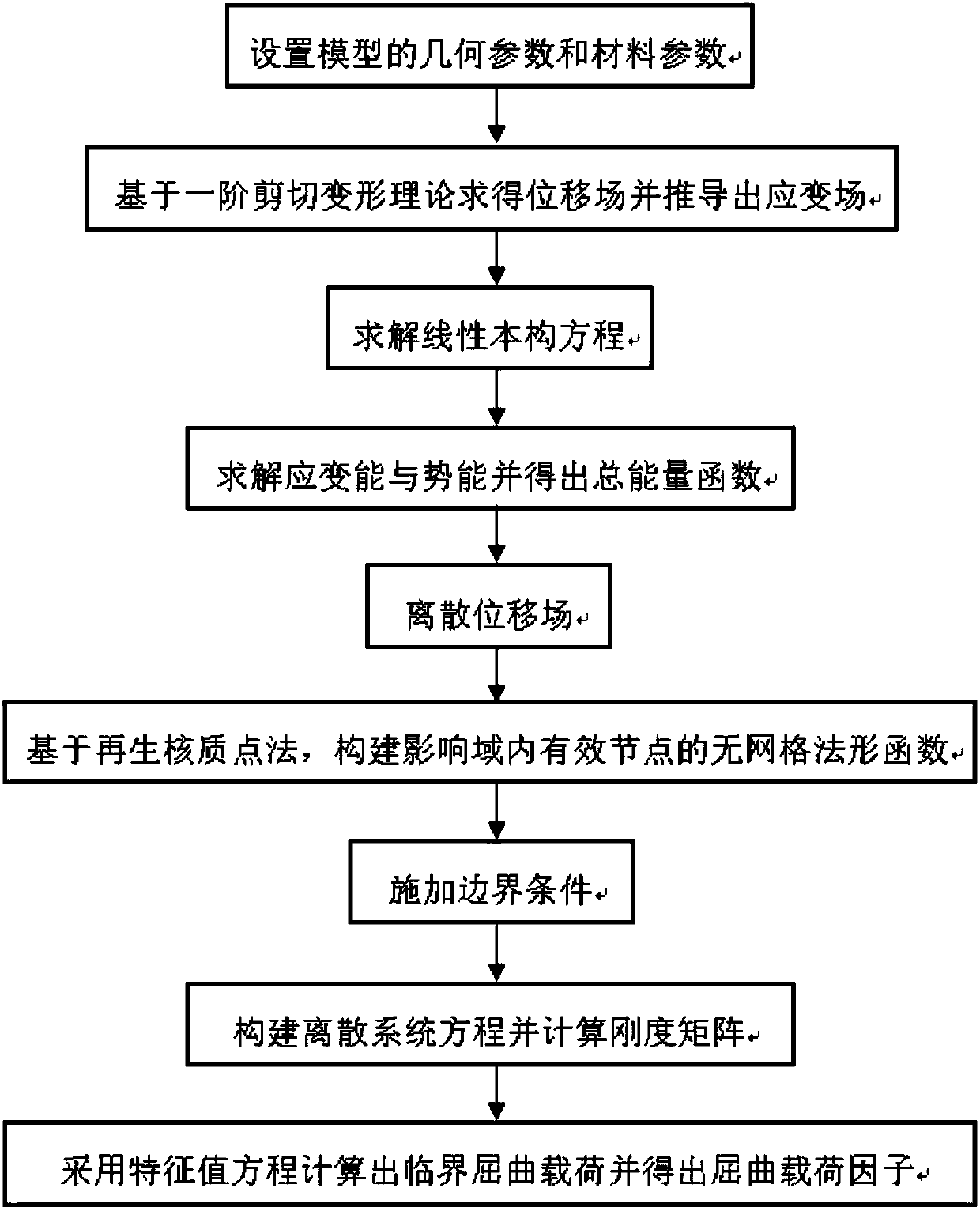

Meshless-method-based numerical algorithm of FG-GRC (functionally-graded graphene-reinforced composite) laminate buckling load factor

A buckling load, meshless technology, applied in CAD numerical modeling, calculation, geometric CAD, etc., can solve the problems of analysis of difficult and complex three-dimensional structures, deviation of calculation results, long calculation time, etc., to achieve good accuracy, Improved accuracy, good smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

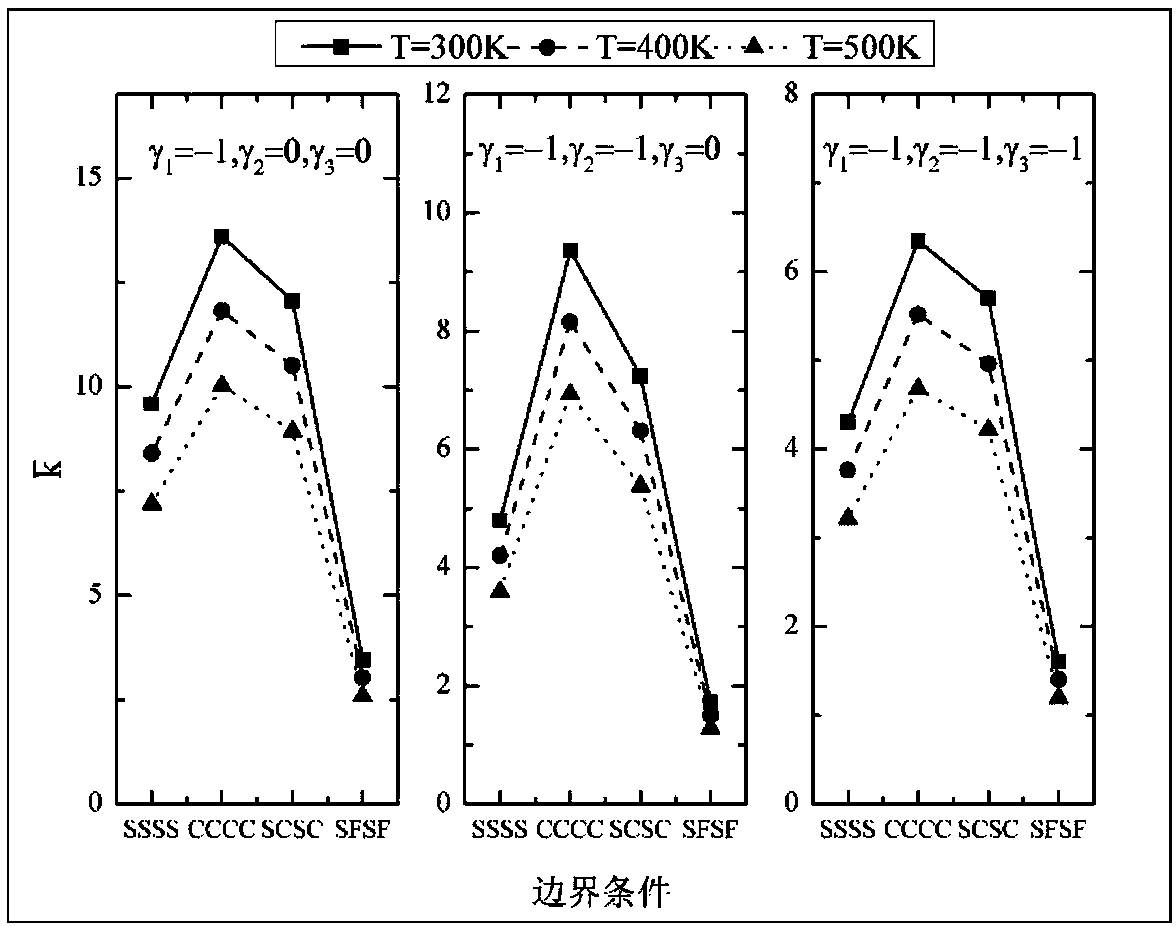

[0156] In order to verify the feasibility of the algorithm scheme, MATLAB programming software was used to write a calculation program for the algorithm, and specific parameters were substituted to solve the buckling load factor of functionally graded graphene reinforced composite laminates.

[0157] Step 1. Build a model, define the geometric parameters and material parameters of the functionally graded graphene-reinforced composite laminate, and use the extended Halpin-Tsai model to solve the overall material parameters of the functionally graded graphene-reinforced composite.

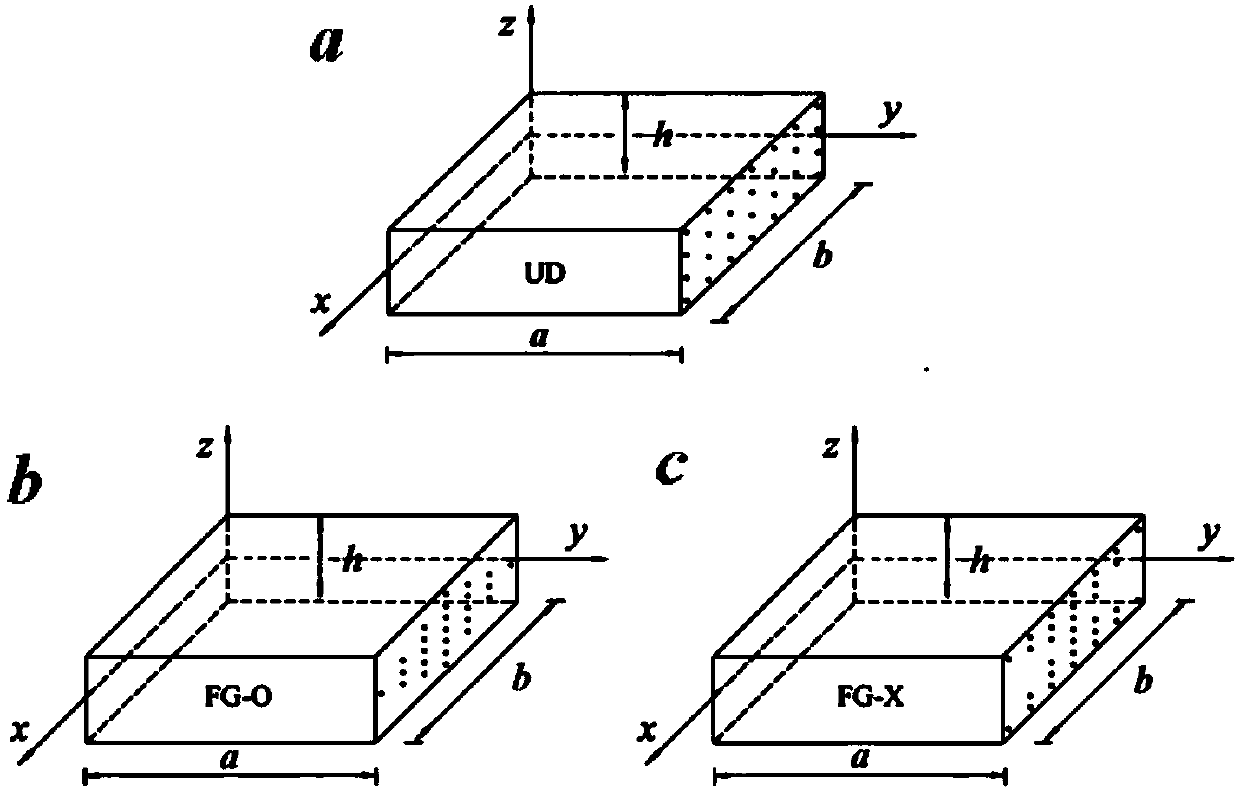

[0158] The geometric parameters of the functionally graded graphene reinforced composite laminate are length a=0.2m, width b=0.2m and height h=0.02m. The distribution forms of graphene-enhanced materials are uniform distribution and functional gradient distribution, respectively: UD, FG-O and FG-X. The geometric parameters of composite laminates and the distribution of graphene are as follows figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com