A kind of thermistor with base and preparation method thereof

A thermistor and pedestal technology, which is applied in the manufacture of resistors, resistors with lead terminals, and resistors with negative temperature coefficients, etc. problem, to achieve the same appearance, improve the safety factor, and solve the effect of easy connection and short circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

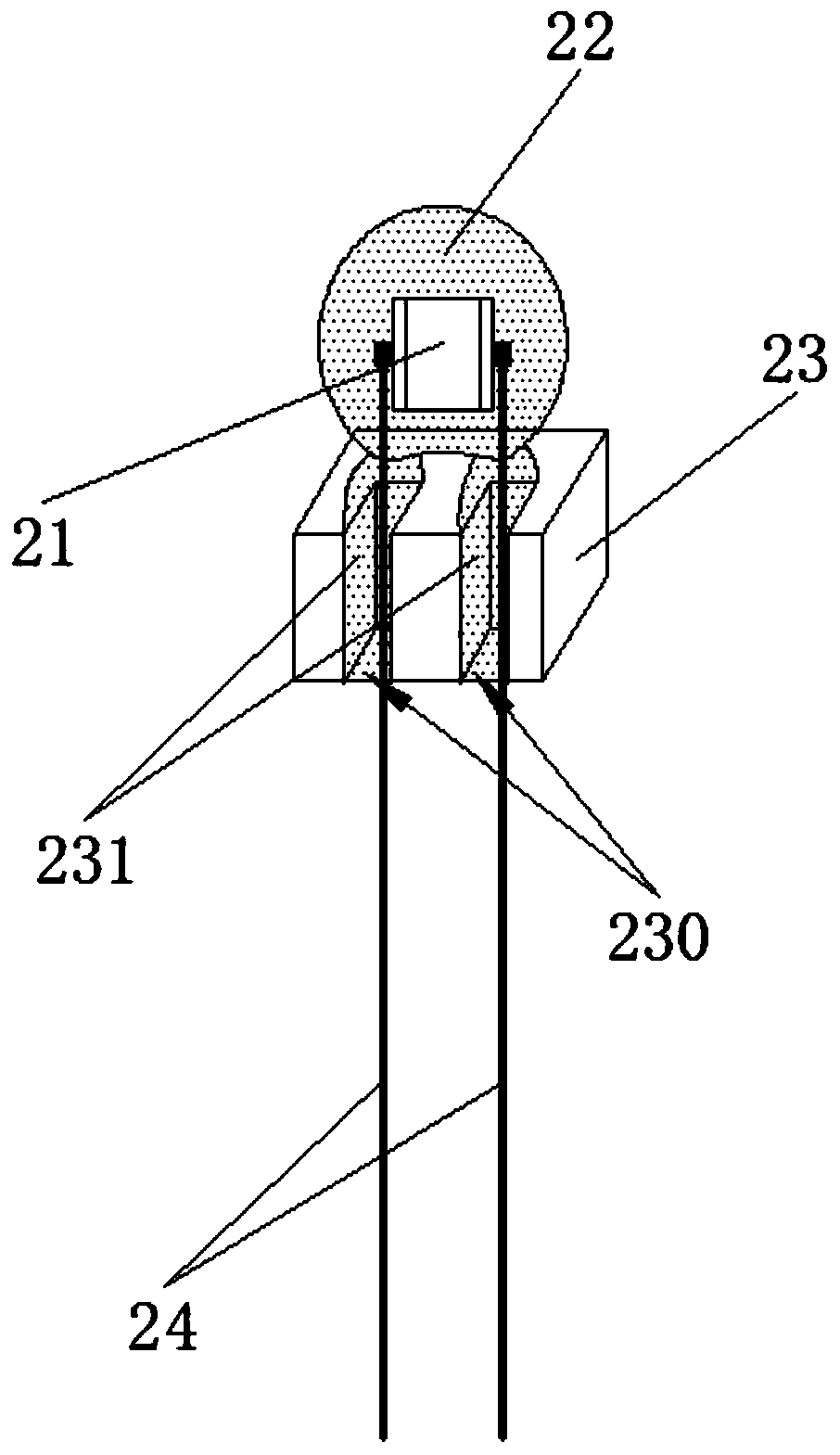

[0039] see figure 2 , which is a structural diagram of the thermistor with a base of the present invention, and the thermistor with a base includes a resistor chip 21 , a glass head 22 , a base 23 and two electrode leads 24 .

[0040]The glass head 22 encapsulates the resistor chip 21 . One ends of the two electrode lead wires 24 are respectively connected to the electrodes at two ends of the resistor chip 21 , and the other ends pass through the bottom of the glass head 22 respectively. The glass head 22 encapsulates the resistor chip 21 and its connection with the two electrode leads 24 . The base 23 is connected and fixed to the bottom of the glass head 22 , and is provided with two lead wire slots 230 , and the two electrode lead wires 24 respectively pass through the two lead wire slots 230 .

[0041] Specifically, the resistance chip 21 is an NTC thermistor chip. The glass head 22 is formed by sintering glass paste.

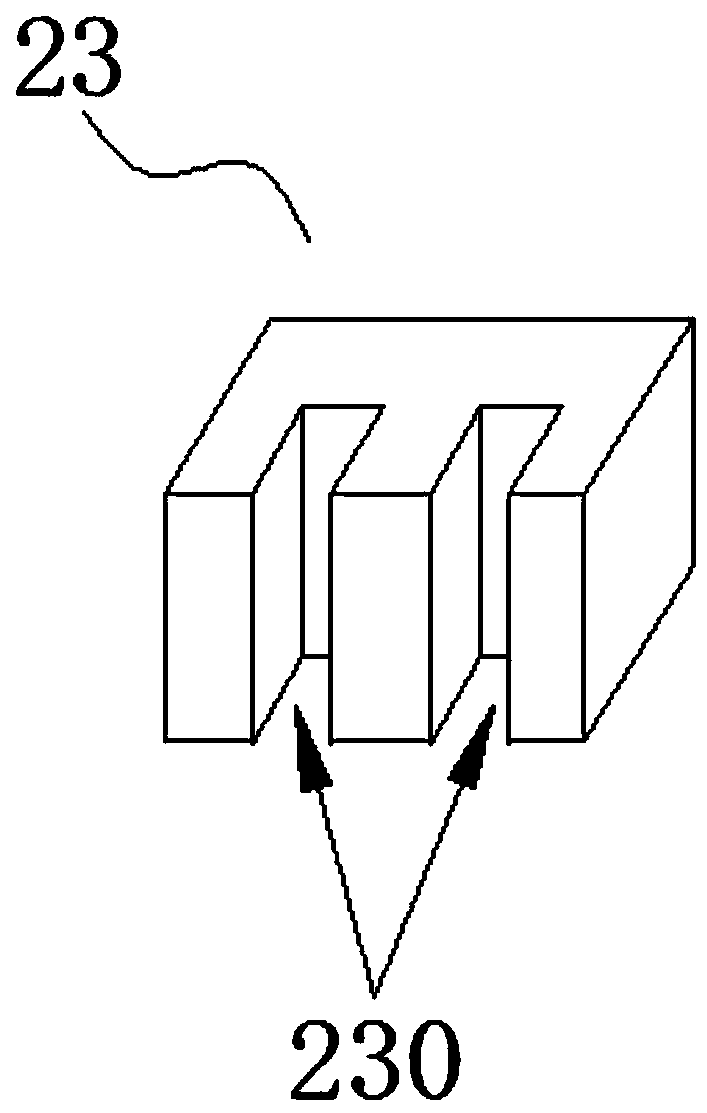

[0042] combine image 3 As shown, the base 23 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com