GaN-based HEMT device and preparation method thereof

A technology of devices and barrier layers, which is applied in the field of GaN-based HEMT devices and its preparation, can solve problems such as limiting the industrialization and application of GaN-based HEMT devices, and large losses, so as to increase the turn-on voltage, improve consistency, and improve breakdown The effect of voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

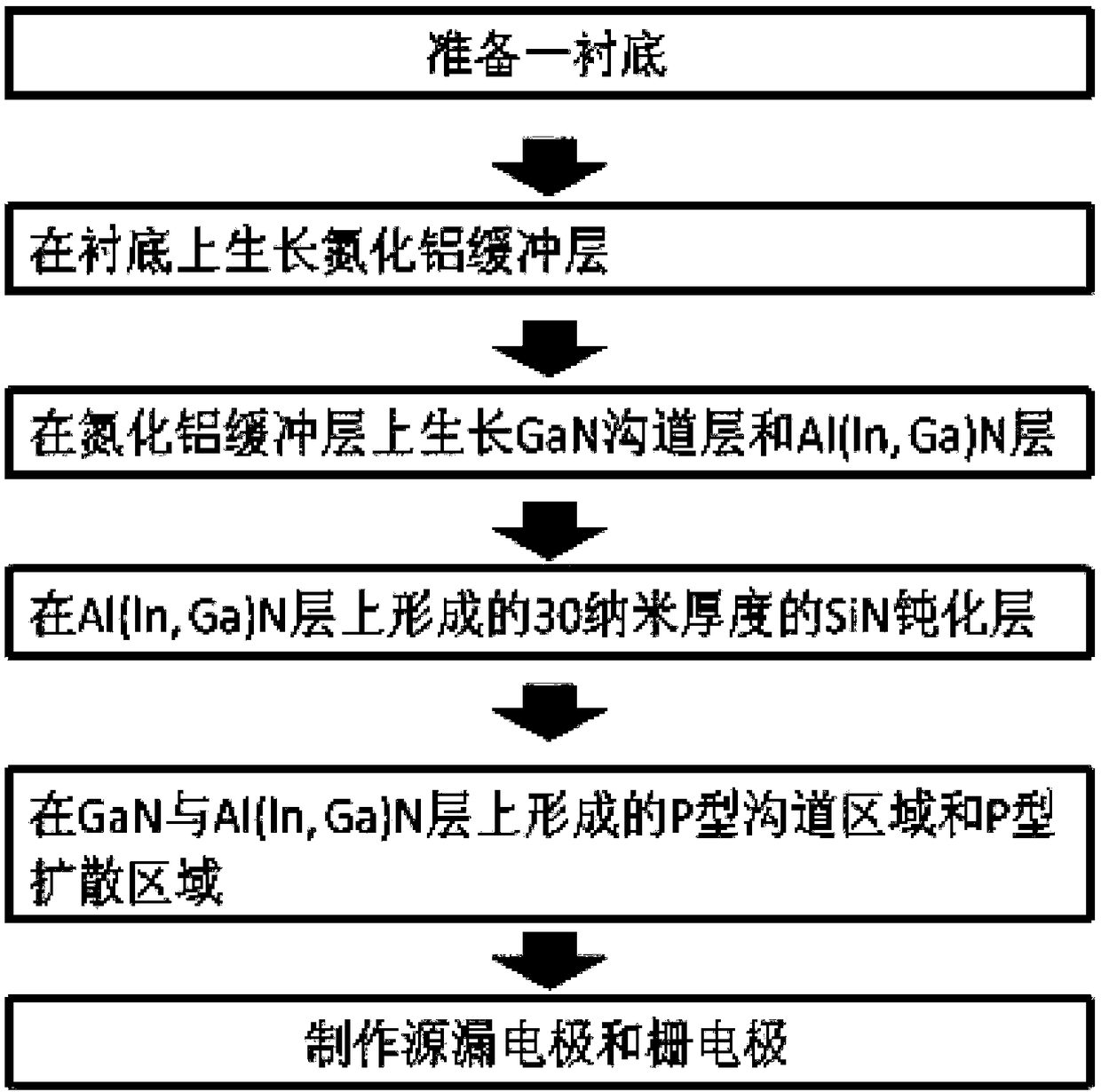

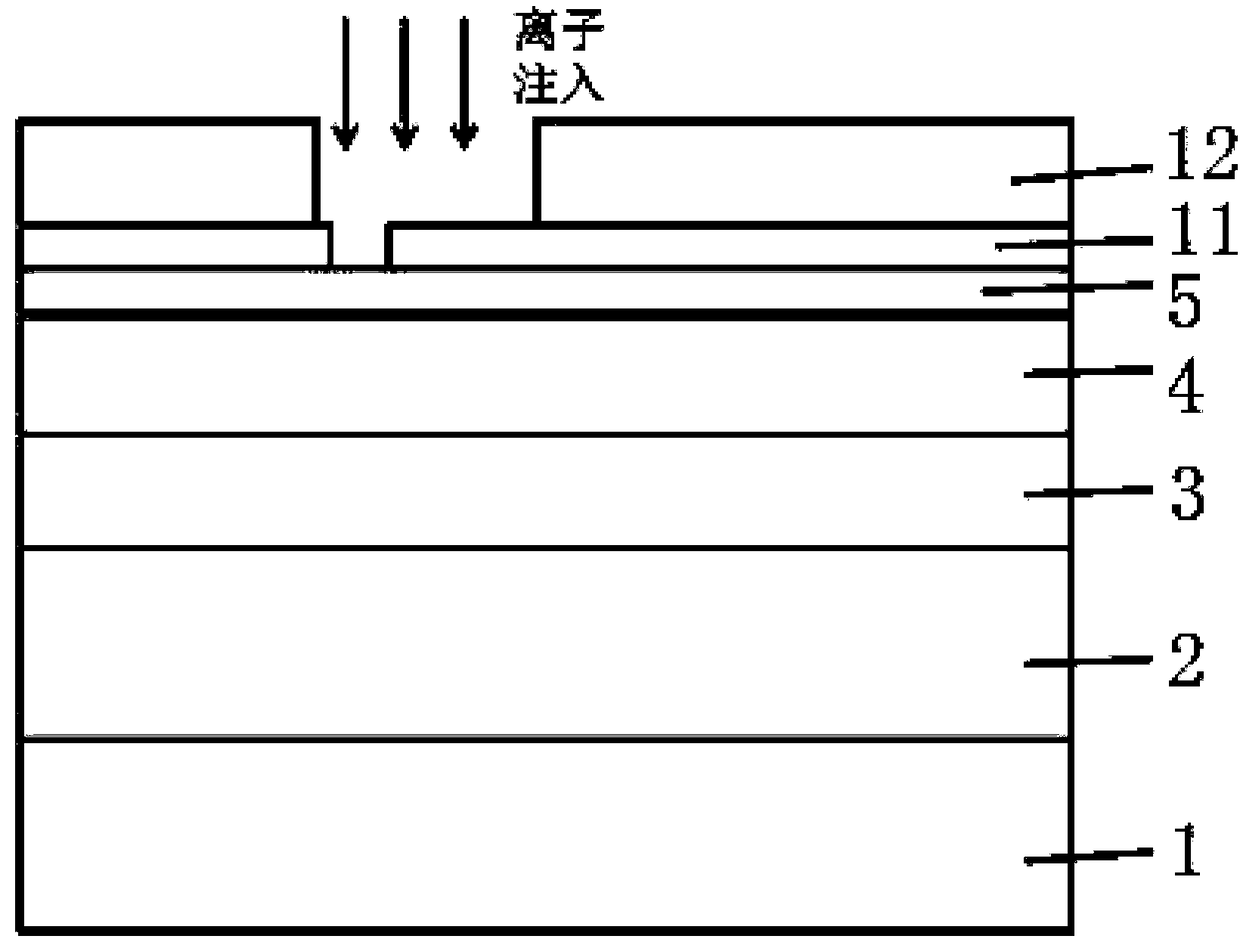

[0046] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

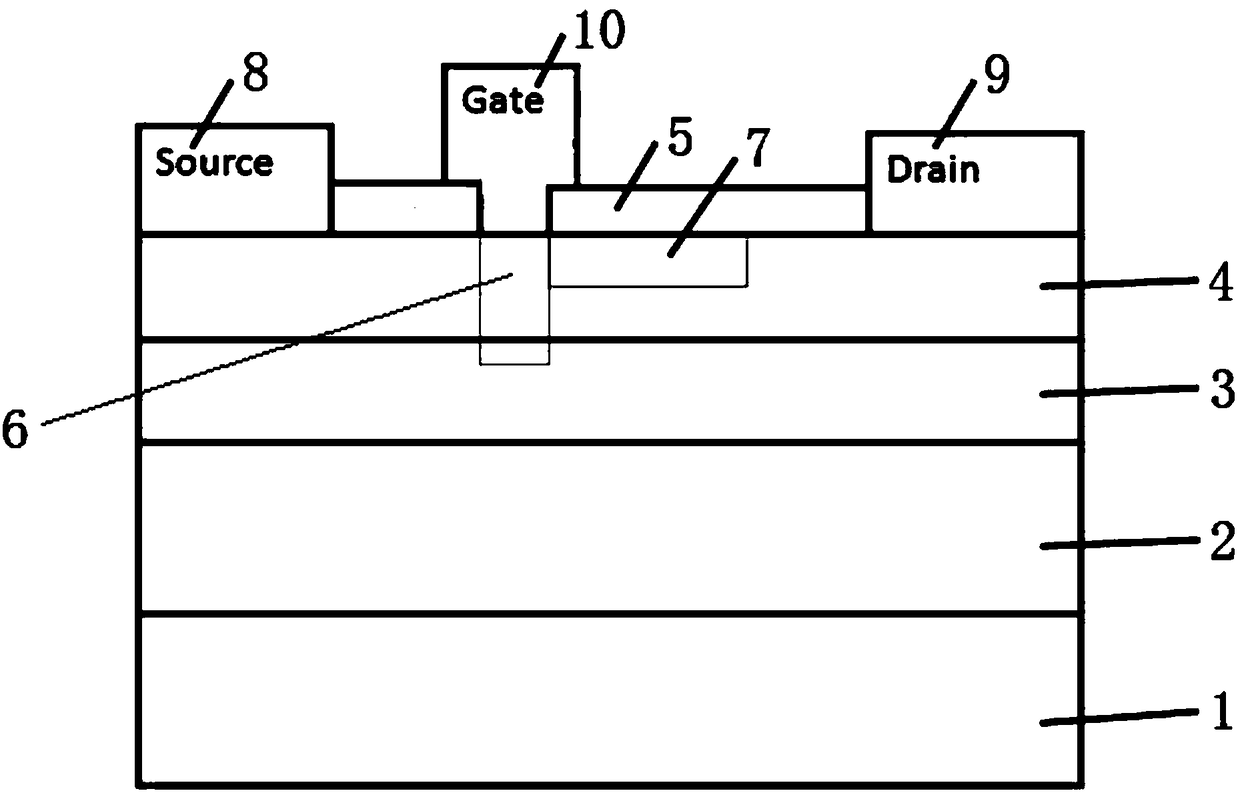

[0047] see figure 1 As shown, the above-mentioned GaN-based HEMT device includes sequentially stacked from bottom to top:

[0048] Substrate layer 1, aluminum nitride buffer layer 2, gallium nitride channel layer 3, Al(ln, Ga, Sc)N barrier layer 4, silicon nitride passivation layer 5.

[0049]The GaN-based HEMT device also includes: a P-type channel region 6 arranged in the gallium nitride channel layer 3 and the Al(ln, Ga, Sc)N barrier layer 4; The P-type diffusion region 7 in the N barrier layer 4; the source electrode 8 and the drain electrode 9 arranged on the upper surface of the Al(ln, Ga, Sc)N barrier layer 4; The gate electrode 10 on the upper surface of the barrier layer 4 is located above the P-type channel region 6 , and the gate electrode 10 is located between the source electrode 8 and the drain electrode 9 ; the P-type diffusio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com