Pulse vibration high-frequency voltage injection-based six-phase permanent magnet synchronous motor sensorless control system and method

A voltage injection, high-frequency pulse vibration technology, applied in the field of permanent magnet synchronous motor sensorless control system, can solve the problems of complex algorithm, low reliability, poor dynamic performance, etc., to achieve simple implementation, strong practicability, and short detection period Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

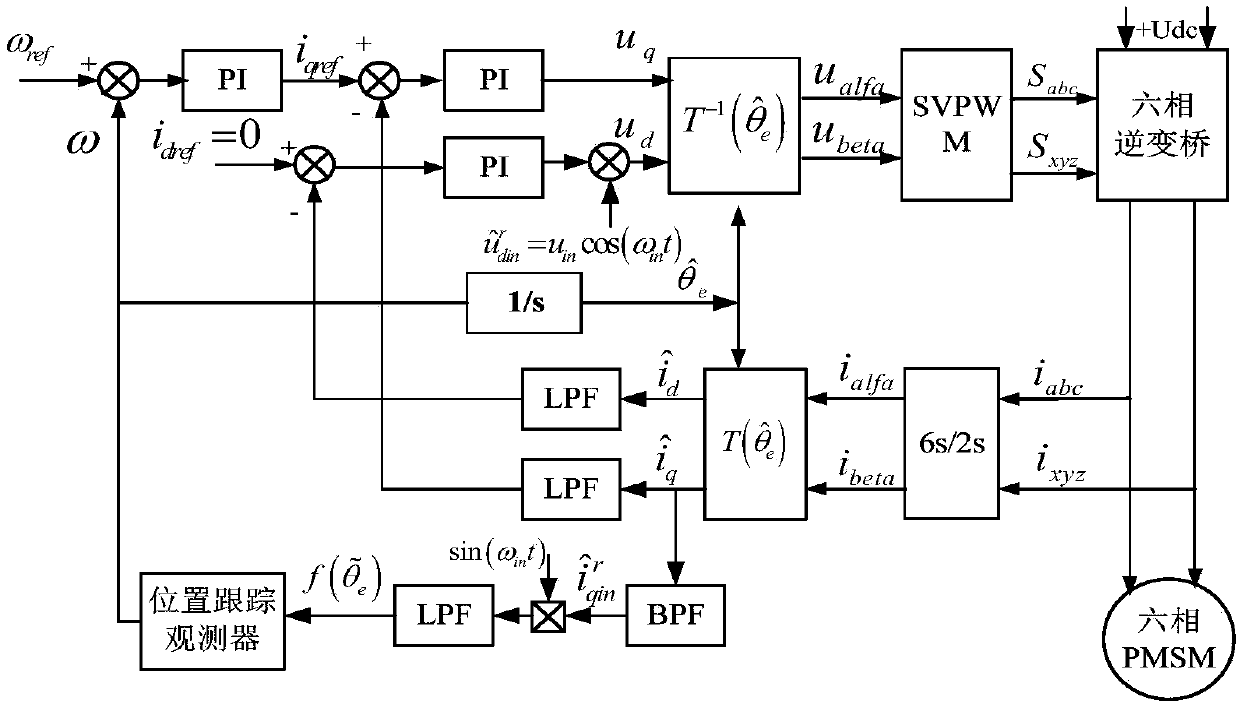

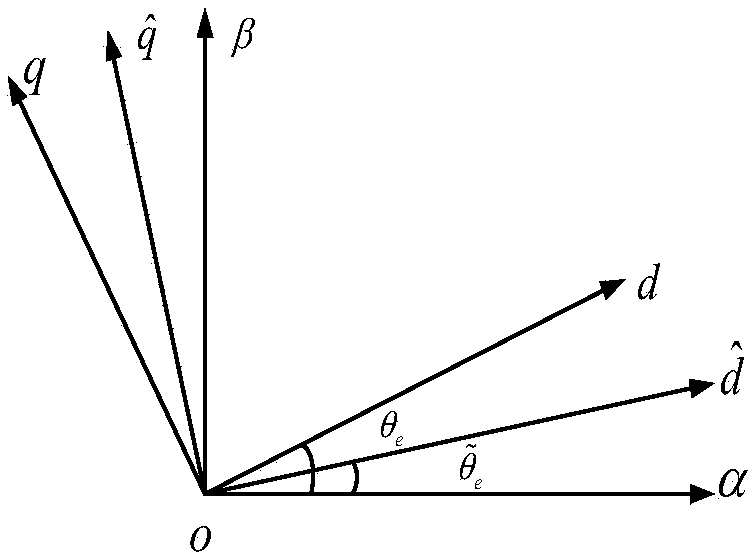

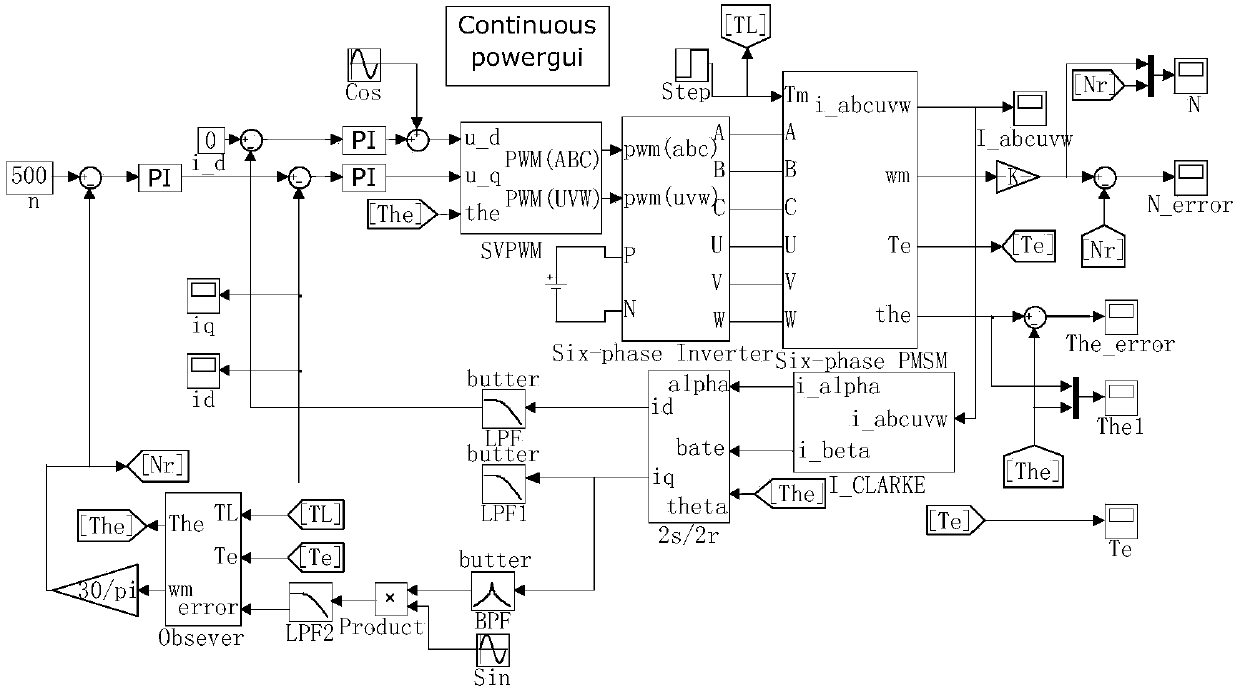

[0024] Such as Figure 1 to Figure 7 As shown, the embodiment of the present invention provides a six-phase permanent magnet synchronous motor sensorless control system based on pulse vibration high-frequency voltage injection. In order to obtain a simplified model that is easy to simulate and analyze, it is necessary to carry out coordinate transformation and The following assumptions are made: air gap magnetomotive force and flux linkage are sinusoidally distributed, magnetic saturation and core loss are ignored, and mutual leakage inductance between windings is ignored.

[0025] The voltage equation of the motor in the natural coordinate system is

[0026]

[0027] The flux equation is

[0028] ψ s =L s i s +γψ fd (2)

[0029] In the formula: u s =[u A u B u C u U u V u W ] T ;

[0030] i s =[i A i B i C i U ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com