Method for calculating heat transfer ratio based on eddy current loss of rotor segmented sheath of permanent magnet motor

A permanent magnet motor and eddy current loss technology, which is applied in the control of generators, motor generators, electromechanical transmissions, etc., can solve the problems of affecting the service life of motors, irreversible loss of magnetization of permanent magnets, high temperature of permanent magnets, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0088] The embodiment of the present invention provides a heat transfer ratio calculation method based on the eddy current loss of the segmented sheath of the permanent magnet motor rotor. By calculating the heat transfer ratio, the heat transfer situation caused by the segmented sheath to the rotor and the influence of the rotor are qualitatively analyzed. degree.

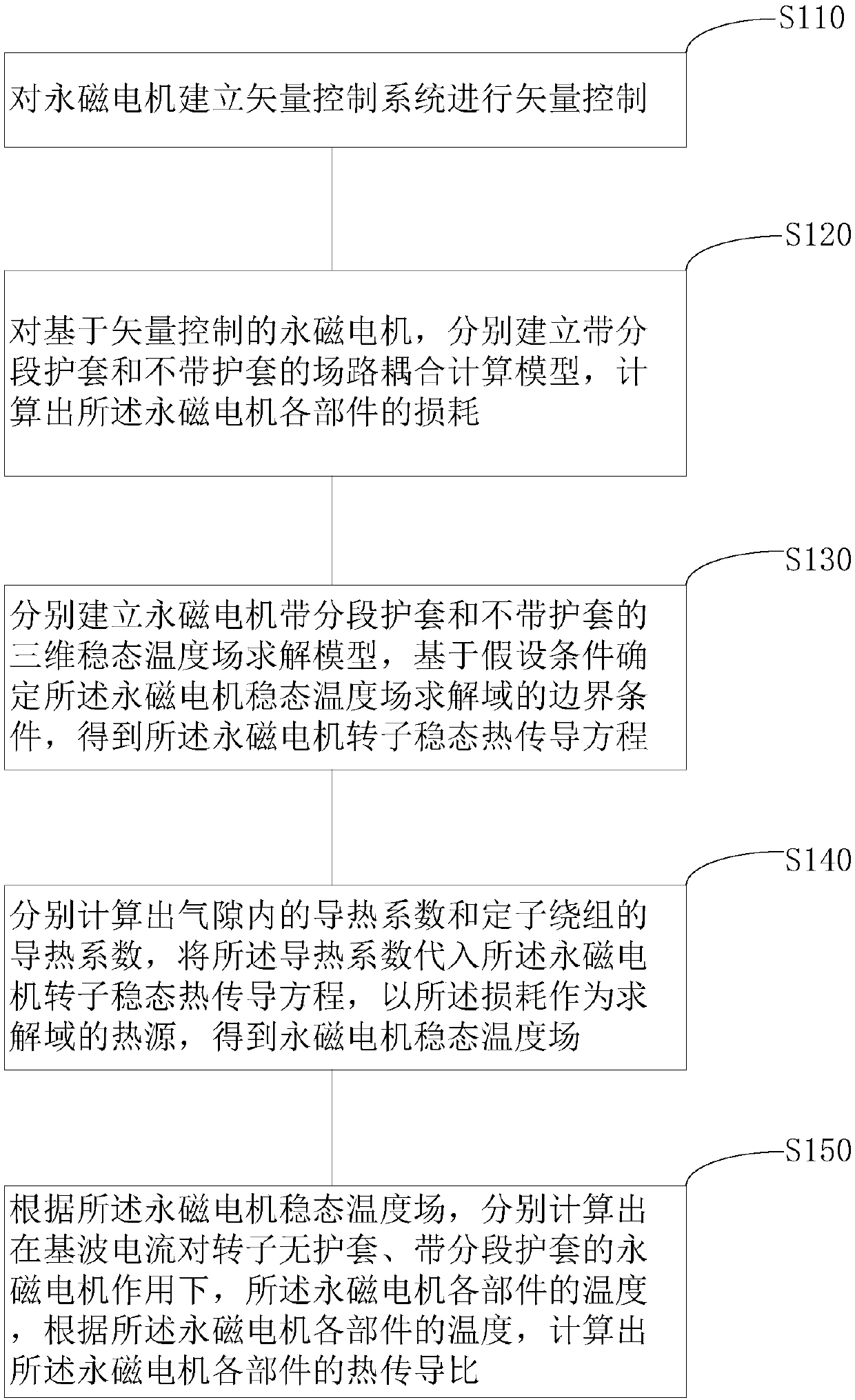

[0089] The processing flow chart of the heat transfer ratio calculation method based on the eddy current loss of the segmented sheath of the permanent magnet motor rotor provided by the embodiment of the present invention is as follows figure 1 As shown, the specific steps are as follows:

[0090] S110: Establish a vector control system for the permanent magnet motor to perform vector control.

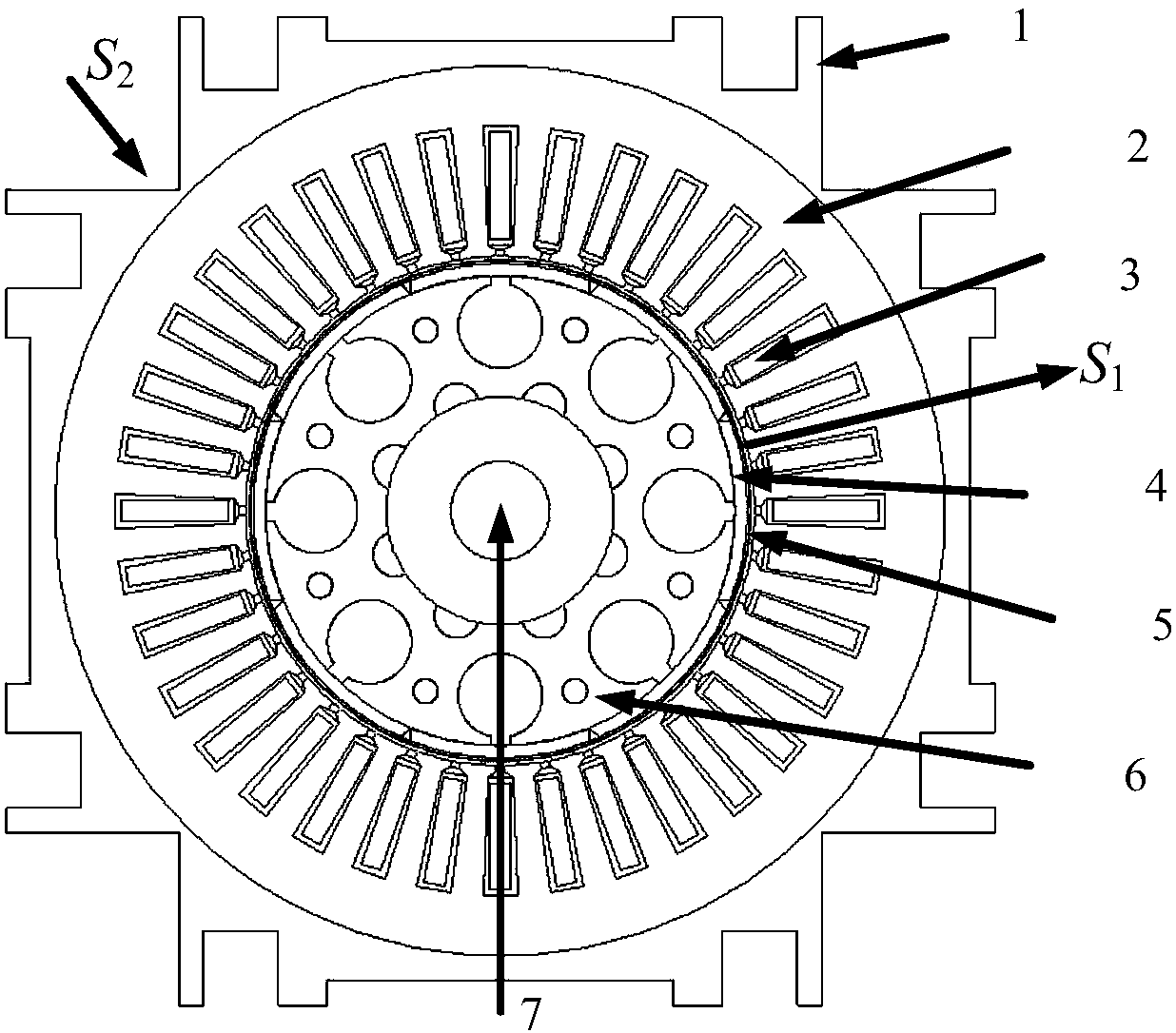

[0091] Such as figure 2 As shown, the permanent magnet motor includes: a casing 1, a stator core 2, a stator winding 3, a permanent magnet 4, a rotor sheath 5, a rotor core 6, and a rotating shaft 7; the casing 1 is loc...

Embodiment 2

[0151] This embodiment provides a method for calculating the heat transfer ratio based on the eddy current loss of the permanent magnet motor rotor section sheath, and specifically analyzes the heat transfer direction inside the permanent magnet motor and the problem of reflecting the degree of heat caused by the permanent magnet motor sheath. The implemented processing flow is as figure 1 shown, specifically as follows:

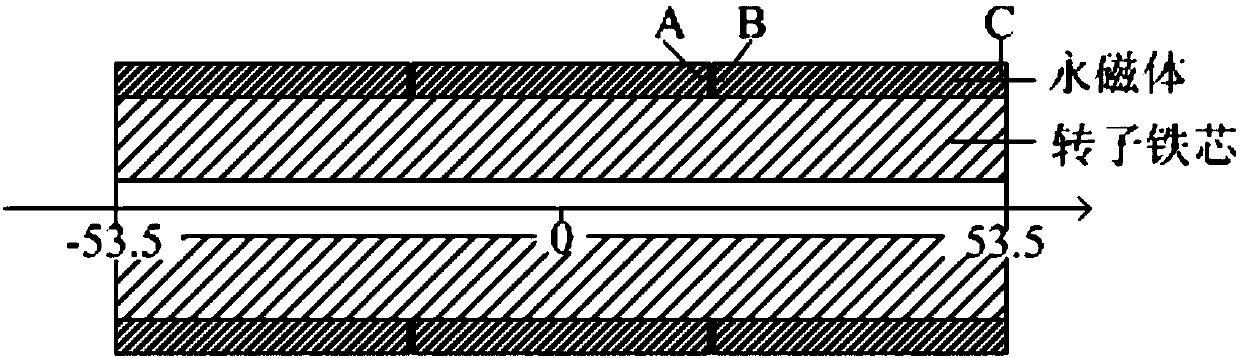

[0152] The structure of a permanent magnet motor includes: a casing, a stator core, a stator winding, an air gap, a rotor core, a segmented rotor sheath, a segmented permanent magnet, and a rotating shaft. The rotor segment sheath is made of conductive and non-magnetic stainless steel material. The rotor segments are symmetrical in the axial direction, and the sheath adopts an axial segmented structure to block the axial flow of current and reduce the eddy current loss on the rotor sheath.

[0153] Table 1 shows the structural dimensions of a permanent mag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com