Li2O-Al2O3-SiO2 series crystallization glass and manufacturing method thereof

A technology of crystallized glass, glass, applied in the field of glass manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Hereinafter, the crystallizable glass and the method for producing the crystallized glass of the present invention will be described.

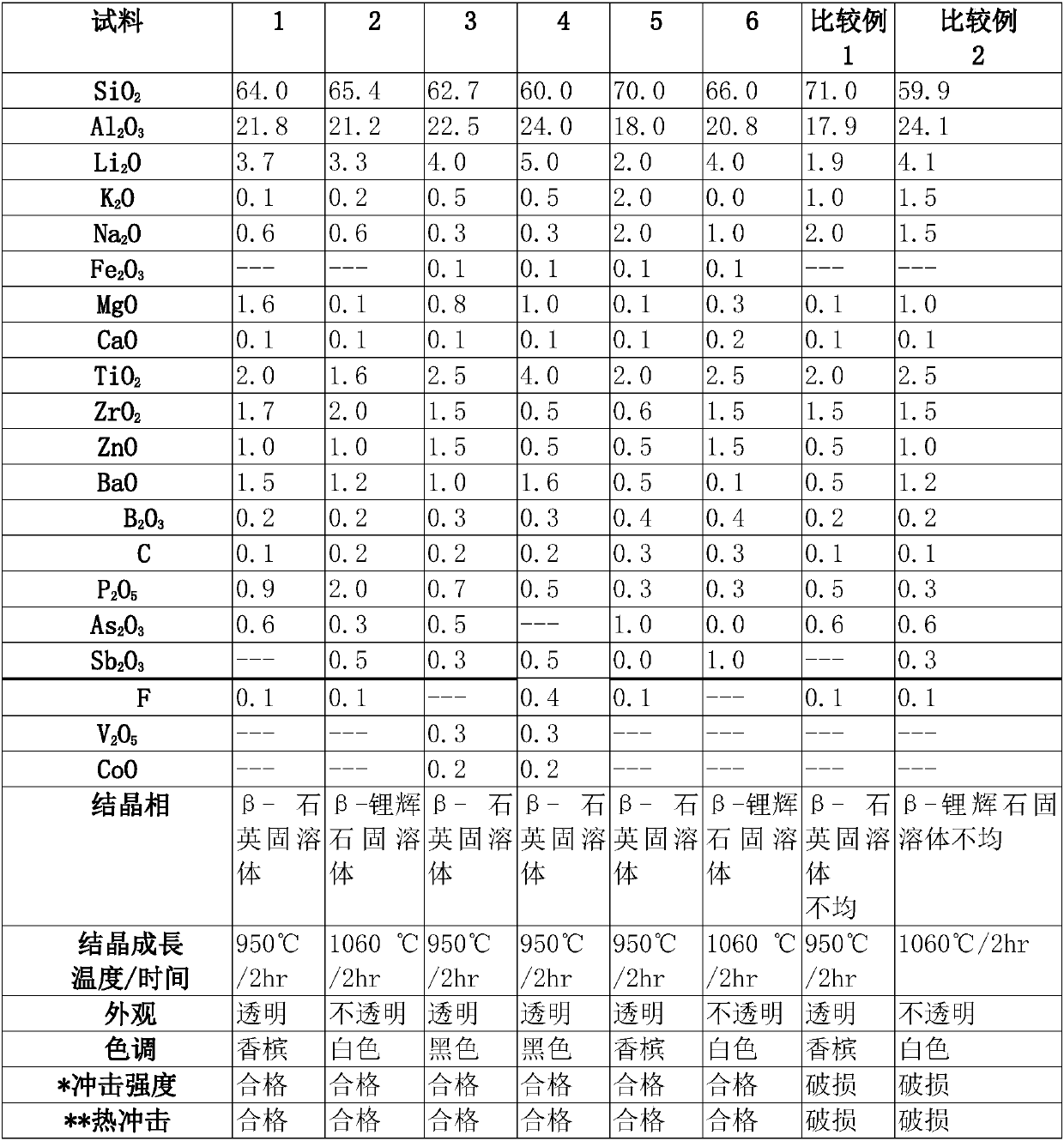

[0046] First, convert the weight percent to SiO 2 60.0~70.0wt%, Al 2 o 3 18.0~24.0wt%, Li 2 O2.0~5.0wt%, TiO 2 0.5~4.0wt%, ZrO 2 0.5~4.0wt%, P 2 o 5 0.3~2.0wt%, Na 2 O0~2.0wt%, K 2 O0~2.0wt%, MgO0.1~1.6wt%, ZnO0.5~2.0wt%, BaO0.1~1.6wt%, As 2 o 3 0~1.0wt%, Sb 2 o 3 0~1.0wt%, F0~1.0wt%, Fe 2 o 3 0~1.0wt%, B 2 o 3 0-1.0wt%, CaO0-1.0wt%, C0-1.0wt% glass raw materials are blended and stirred evenly. Lithium-containing waste is used as the main raw material.

[0047] As lithium-containing waste, the content of each component is SiO 2 55.0~75.0wt%, Al 2 o 3 15.0~25.0wt%, Li 2 O0.5~5.0wt%, TiO 2 0~4.0wt%, ZrO 2 0~4.0wt%, P 2 o 5 0~2.0wt%, Na 2 O0~2.0wt%, K 2 O0~2.0wt%, MgO0~2.0wt%, ZnO0~2.5wt%, BaO0~2.0wt%, As 2 o 3 0~1.0wt%, Sb 2 o 3 0~1.0wt%, F0~1.0wt%, Fe 2 o 3 0~1.0wt%, B 2 o 3 The composition of 0-1.0 wt%...

Embodiment 2

[0062] Mix the glass raw material into the composition of sample number 2 shown in Table 1 and place it in the crucible, melt the glass raw material at 1650°C and make a plate-shaped test piece of 100mm×100mm×5mm, after cooling, put the glass plate into heat treatment In the furnace, after holding the temperature at 200°C for 10 minutes, the temperature was raised to 1060°C at a rate of 1°C / min, and the furnace was cooled after holding the temperature at 1060°C for 20 minutes. As a result, β-spodumene solid solution (Li 2 O·Al 2 o 3 · nSiO2 2 n≧4) and become white crystallized glass.

Embodiment 3

[0064] Mix the glass raw material into the composition of sample number 3 shown in Table 1 and put it in the crucible, melt the glass raw material at 1650°C and make a plate-shaped test piece of 100mm×100mm×5mm, after cooling, put the glass plate into heat treatment In the furnace, after holding the temperature at 200°C for 10 minutes, the temperature was raised to 950°C at a rate of 1°C / min, and the furnace was cooled after holding the temperature at 950°C for 20 minutes. As a result, β-quartz solid solution (Li 2 O·Al 2 o 3 · nSiO2 2 n≧2) and become black transparent crystallized glass.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com