Circulating water cooling system and method

A technology of circulating water cooling and cooling system, used in water shower coolers, refrigerators, refrigeration components, etc., can solve the problems of 24-hour work, complex structure, high energy consumption, and achieve obvious water-saving effect and equipment. The effect of obvious investment and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

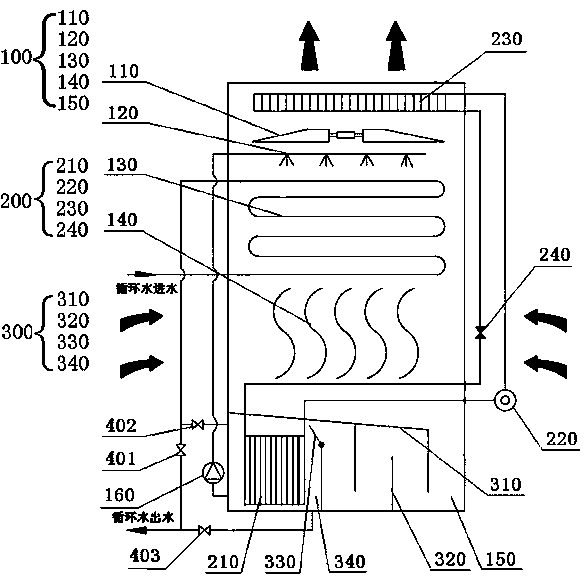

[0051] Circulating water cooling system of the present invention, its schematic diagram is as figure 1 As shown, it includes a closed tower cooling system 100, a diversion system 300 and a heat pump system 200;

[0052] The closed tower cooling system 100 includes a fan 110, a shower 120, a heat exchange coil 130, a heat exchange layer 140, and a water collection tank 150 arranged in sequence from top to bottom, and the two ends of the heat exchange coil 130 are respectively connected to Circulating water enters and exits, and the sump 150 is connected to the sprinkler through a circulating water pump 160;

[0053] The deflector system 300 includes a baffle sloping plate 310 , a baffle 320 , a control door 330 and an evaporation chamber 340 . The baffle sloping plate 310 is arranged on the top of the sump 150 and slopes downward from one side of the sump 150 . Extending to the other side of the sump 150, the deflector 320 is provided with multiple pieces, which are arranged s...

Embodiment 2~5

[0057] The mode that embodiment 2~5 utilizes above-mentioned circulating water cooling system to carry out cooling:

Embodiment 2

[0059] Select a day in September in this area, the highest temperature of the day is 29°C, and the relative humidity is 45%. The converted maximum wet bulb temperature is 20.26°C, the minimum temperature is 18°C, and the relative humidity is 55%. The converted minimum wet bulb temperature is 12.8°C.

[0060]The working mode of the cooling system in a day is: open the closed tower cooling system 100, close the heat pump system 200, open the valve A401, close the valve B402 and the valve C403, and open the control door 330; The shower 120 water pump units can be turned on half of the number, the fan 110 works at a lower speed, gradually increases the power as the temperature rises, and meets the index of circulating water outlet temperature of 30°C; the period from noon to afternoon is the highest in a day. At this time, the sprayer 120 water pump unit is fully turned on, and the fan 110 works at a higher speed; in the evening to late night, the temperature gradually decreases, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com