Paper defect detection system for medical test paper

A technology of paper defect detection and test paper, which is applied in the field of paper defect detection system of medical test paper, can solve the problems of undescribed paper defect follow-up processing device, algorithm processing has little reliability, etc., and achieve accurate and rapid paper defect detection and marking, The effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

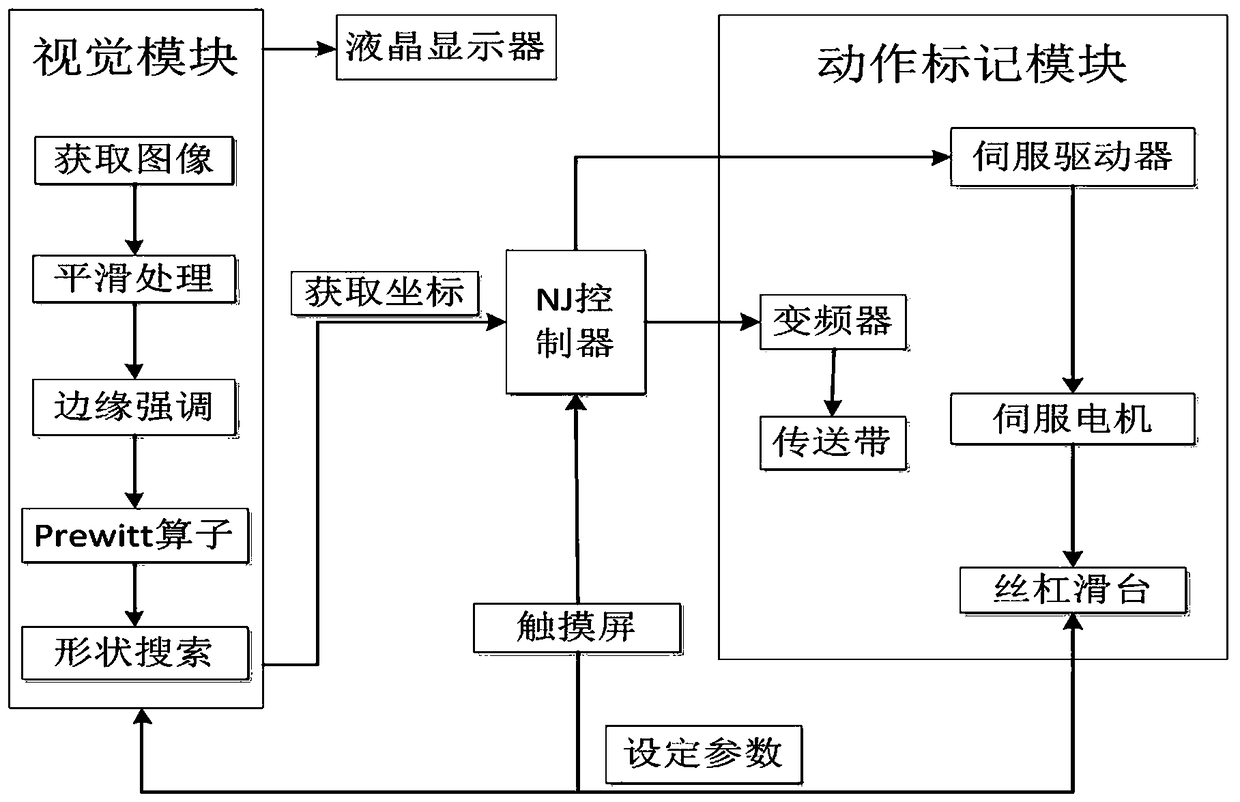

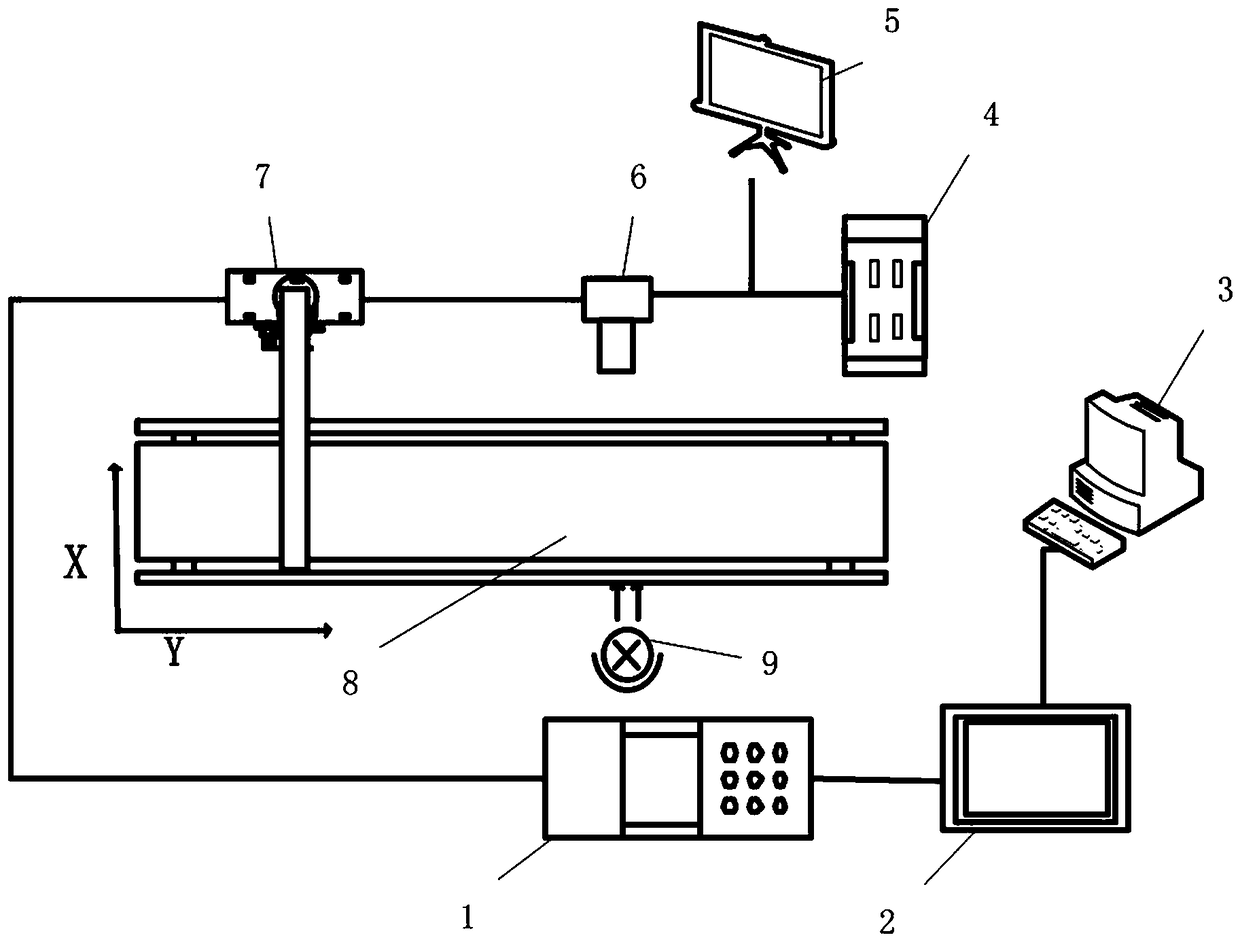

[0024] refer to Figure 1-2 , a paper defect detection system for medical test strips, consists of three parts: a visual detection module, an action marking module and a human-computer interaction module, and each part is connected through the EtherCAT bus. With OMRON NJ series controller as the core; the visual detection part is composed of industrial camera, visual processor, LED dot matrix light source and liquid crystal display, visual detection is used as the input part of the whole system, and the specific coordinates of the paper defect are obtained through image collection and algorithm processing position, and transmit the position data to the NJ controller; the action marking part is composed of a servo driver, a frequency converter and a servo motor. The NJ controller obtains the coordinate position of the visual part and performs data analys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com