Automatic punching machine monitoring system

A monitoring system and stamping machine technology, applied in general control system, control/adjustment system, program control, etc., can solve the problems of machine reliability gap, low idle speed and working speed, low control accuracy, etc., and achieve system Accelerated response speed, good dynamic characteristics, and the effect of solving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with drawings and embodiments.

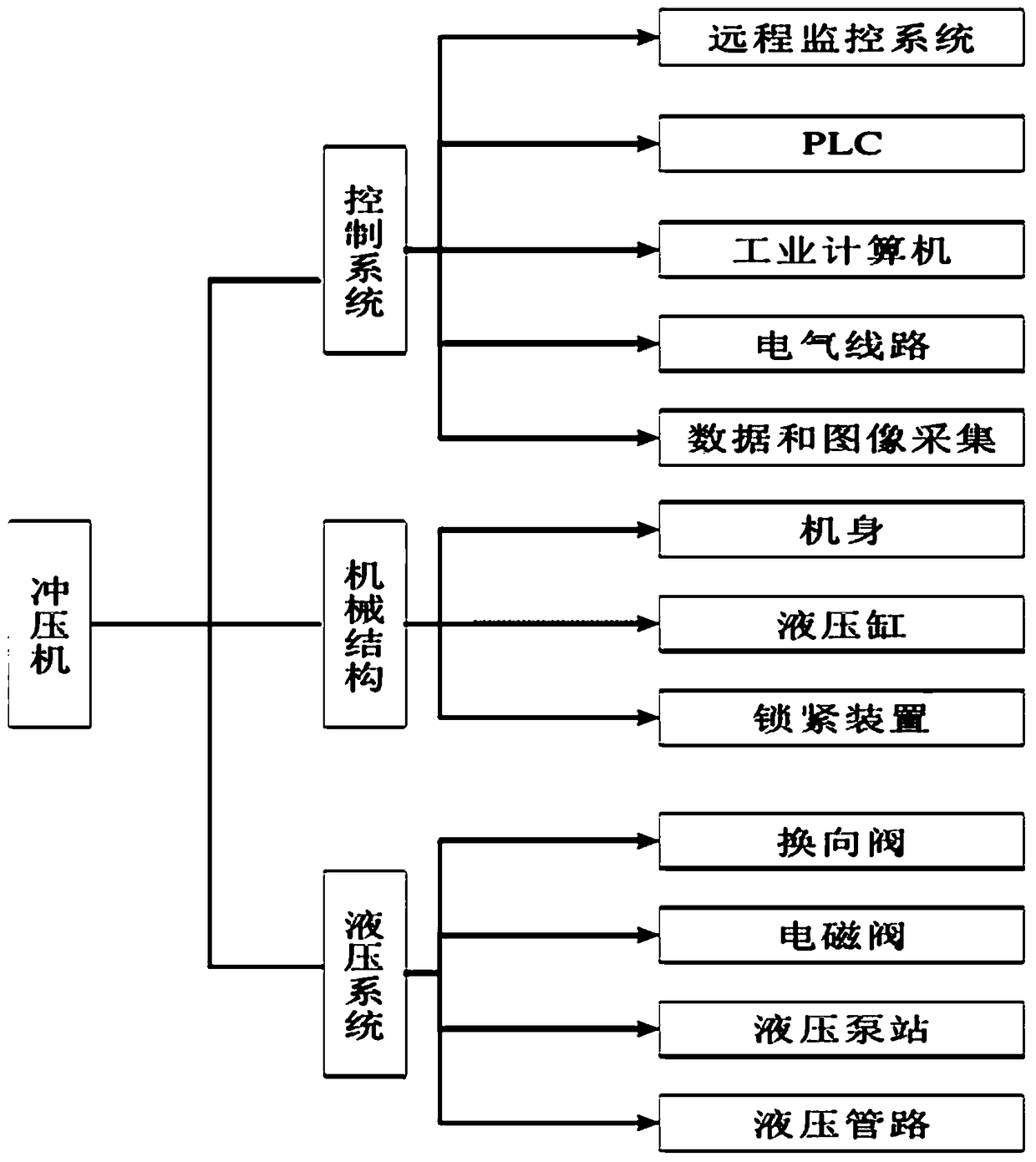

[0020] Such as figure 1 , the automatic stamping machine is a high-performance, fully automatic, mechatronic automation equipment with the required operation and video monitoring functions. and video surveillance system. The design of the whole system is divided into three aspects: mechanical structure design, electrical design and control system design.

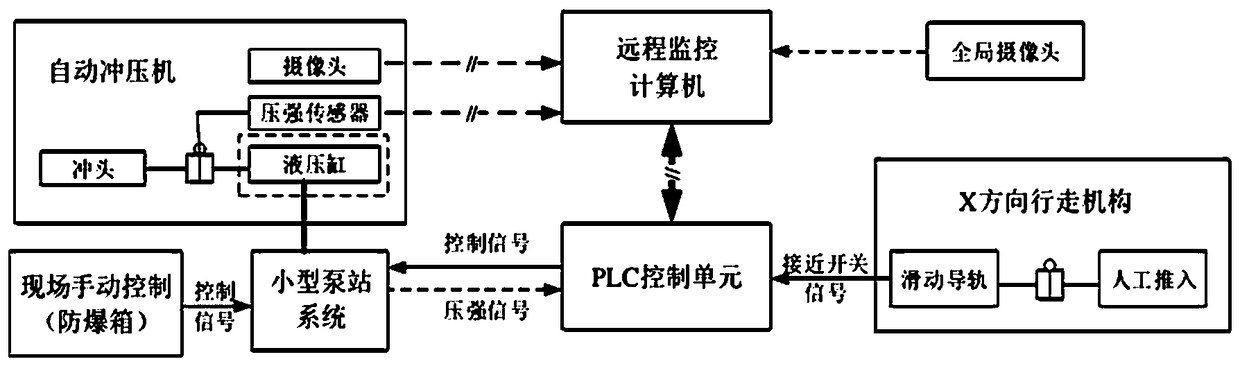

[0021] Such as figure 2 , In the hydraulic press control system, the demand analysis of the system includes two levels: the bottom control level and the remote monitoring level. The operation process control is based on the operating specifications of the hydraulic press, so that the hydraulic press can operate safely and efficiently in accordance with the specifications. Data acquisition and processing enable PLC to automatically collect the status information of hydraulic system pressure, punch displacement and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com