Linear servo position tracking control based on linear matrix inequality and sliding mode control

A linear matrix, tracking controller technology, applied in the field of numerical control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

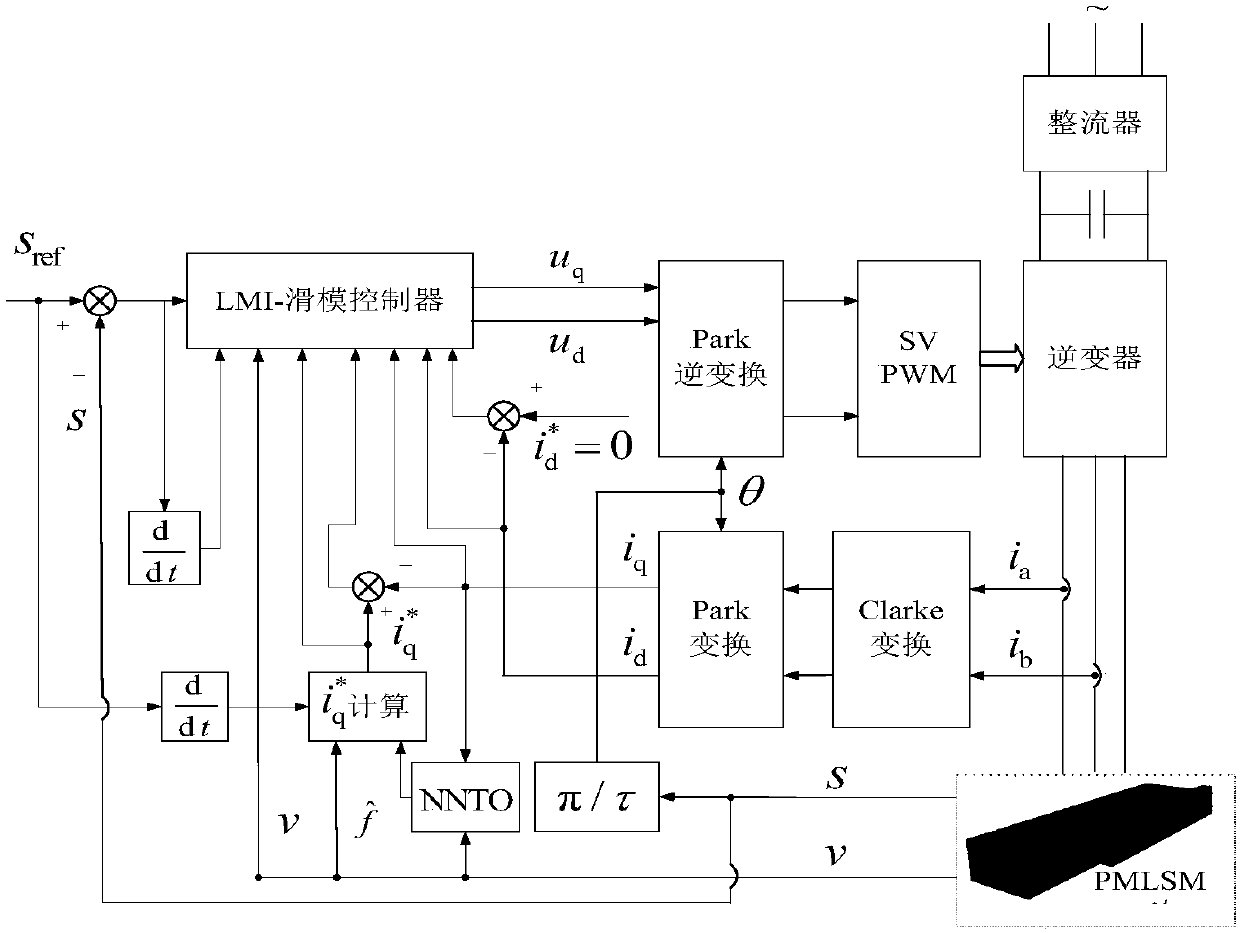

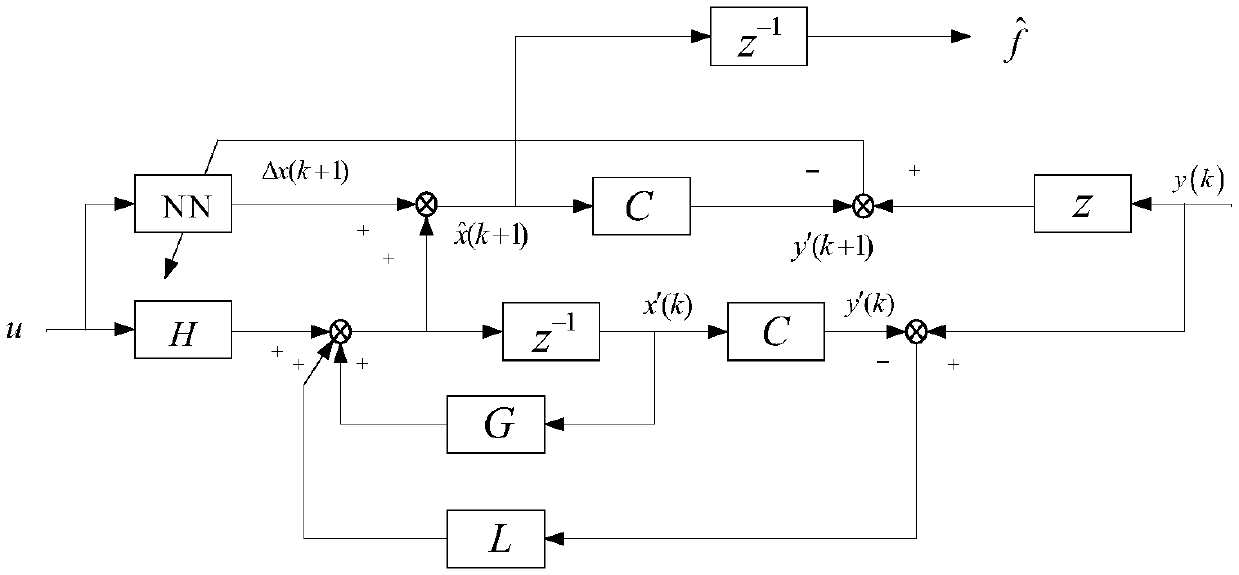

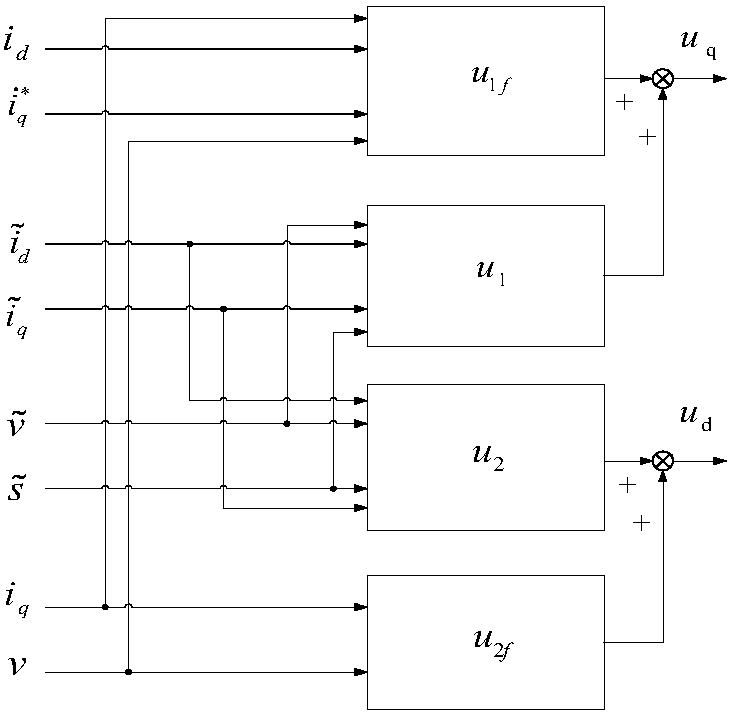

[0096] Embodiments of the present invention provide a linear servo position tracking control system and method based on a combination of linear matrix inequality and sliding mode control, which can achieve good robust speed tracking performance for position commands in high-speed and high-precision situations.

[0097] Realize the concrete steps of the present invention as follows:

[0098] Step 1: The nonlinear mathematical model of the permanent magnet linear synchronous motor is established.

[0099] The axis of the permanent magnet's fundamental excitation field is taken as the d-axis, and its counterclockwise rotation of 90° electrical angle is taken as the q-axis, so that the current vector of the mover is orthogonal to the magnetic field of the stator in space. Neglecting magnetic circuit saturation, the nonlinear dynamic mathematical model can be expressed as follows:

[0100]

[0101]

[0102] ψ d =L d i d +ψ f (7)

[0103] ψ q =L q i q (8)

[0104] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com