Preparation method of cuttlefish powder

A technology of cuttlefish ink and cuttlefish, which is applied in the direction of food science, etc., can solve the problem that the cuttlefish ink cannot be processed in time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

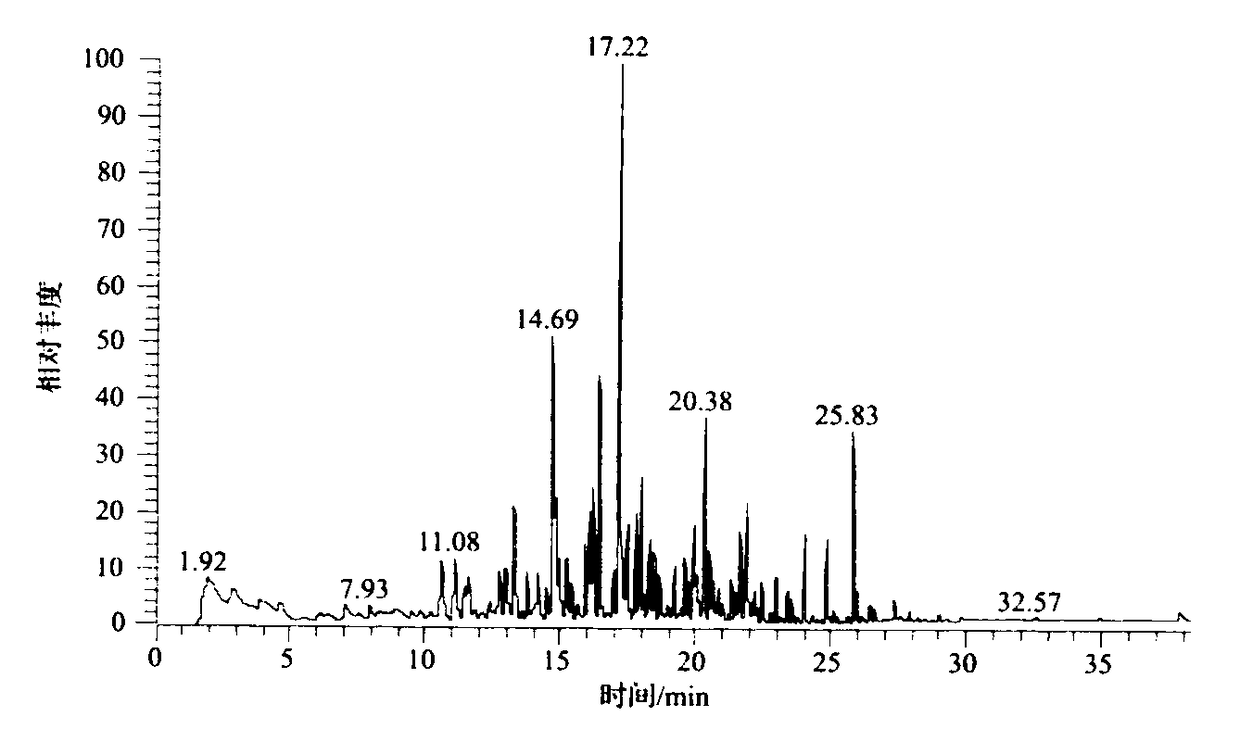

Embodiment 1

[0037] A preparation method of cuttlefish toner, comprising the following steps:

[0038] (1) get fresh cuttlefish, dissect and kill, get its ink sac, collect Chinese ink;

[0039] (2) The ink is treated with irradiation; the irradiation dose is (2-5)×10 4 Gy;

[0040] (3) Add L-cysteine, maltodextrin, fructose, carboxypeptidase B and malic acid in ink, the ratio of ink and each component is 100:2:7:3:1:0.1, then React at 40-50°C for 30-40min;

[0041] (4) Then add 3% citric acid, 2% glucose, 0.5% methionine, and react at 100°C for 10-15min, after stirring, let stand at room temperature for 12-20h; and adjust the pH to 6-6.5;

[0042] (5) Add β-cyclodextrin to the reaction product, the mass ratio of β-cyclodextrin is 0.2%, stir and react at 30-35°C for 10-30min; and adjust the pH to 6.5;

[0043] (6) Take off the suspension of the lower layer, and centrifuge to obtain the precipitate;

[0044] (7) drying the precipitate at 50-60° C. to obtain cuttlefish powder.

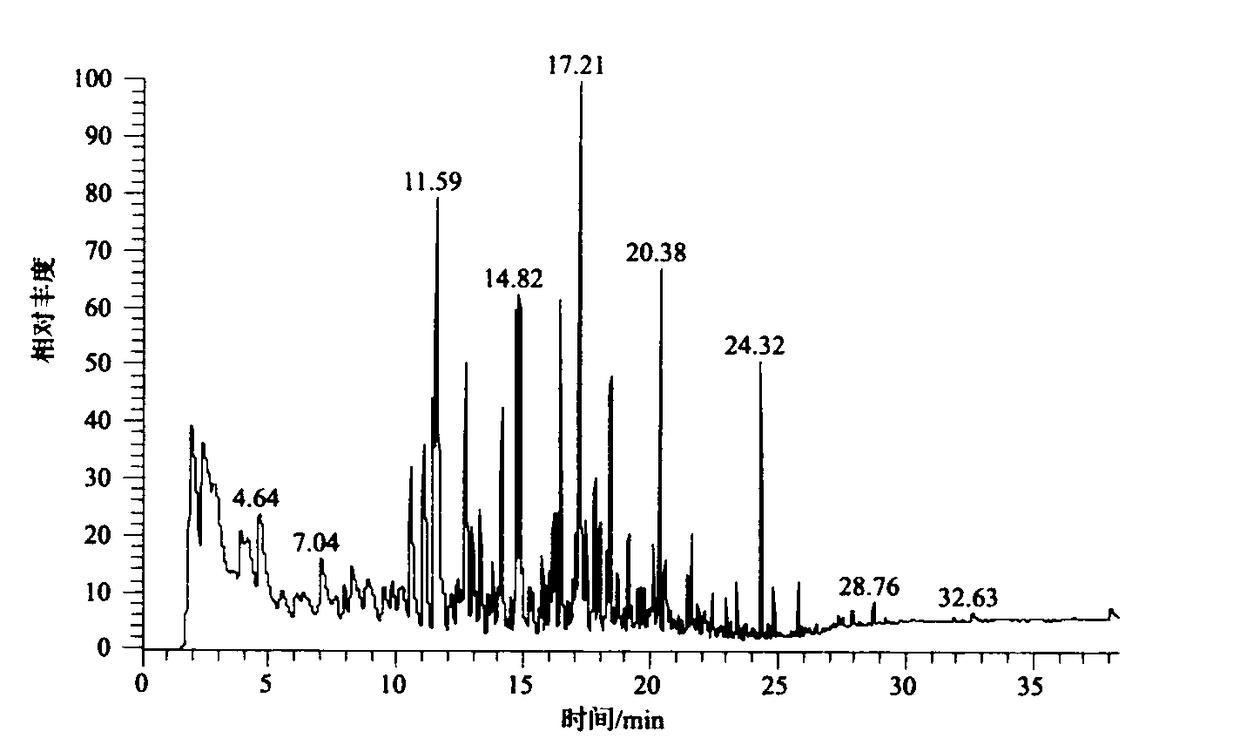

Embodiment 2

[0046] A preparation method of cuttlefish toner, comprising the following steps:

[0047] (1) get fresh cuttlefish, dissect and kill, get its ink sac, collect Chinese ink;

[0048] (2) The ink is treated with irradiation; the irradiation dose is (2-5)×10 4 Gy;

[0049] (3) Add L-cysteine, maltodextrin, fructose, carboxypeptidase B and malic acid in ink, the ratio of ink and each component is 100:3:5:5:0.5:0.3 successively, and then React at 40-50°C for 30-40min;

[0050] (4) Then add 1% citric acid, 5% glucose, and 0.3% methionine, and react at 100°C for 10-15min, after stirring, let stand at room temperature for 12-20h; and adjust the pH to 6-6.5;

[0051] (5) Add β-cyclodextrin to the reaction product, the mass ratio of β-cyclodextrin is 0.4%, stir and react at 30-35°C for 10-30min; and adjust the pH to 6.5;

[0052] (6) Take off the suspension of the lower layer, and centrifuge to obtain the precipitate;

[0053] (7) drying the precipitate at 50-60° C. to obtain cuttle...

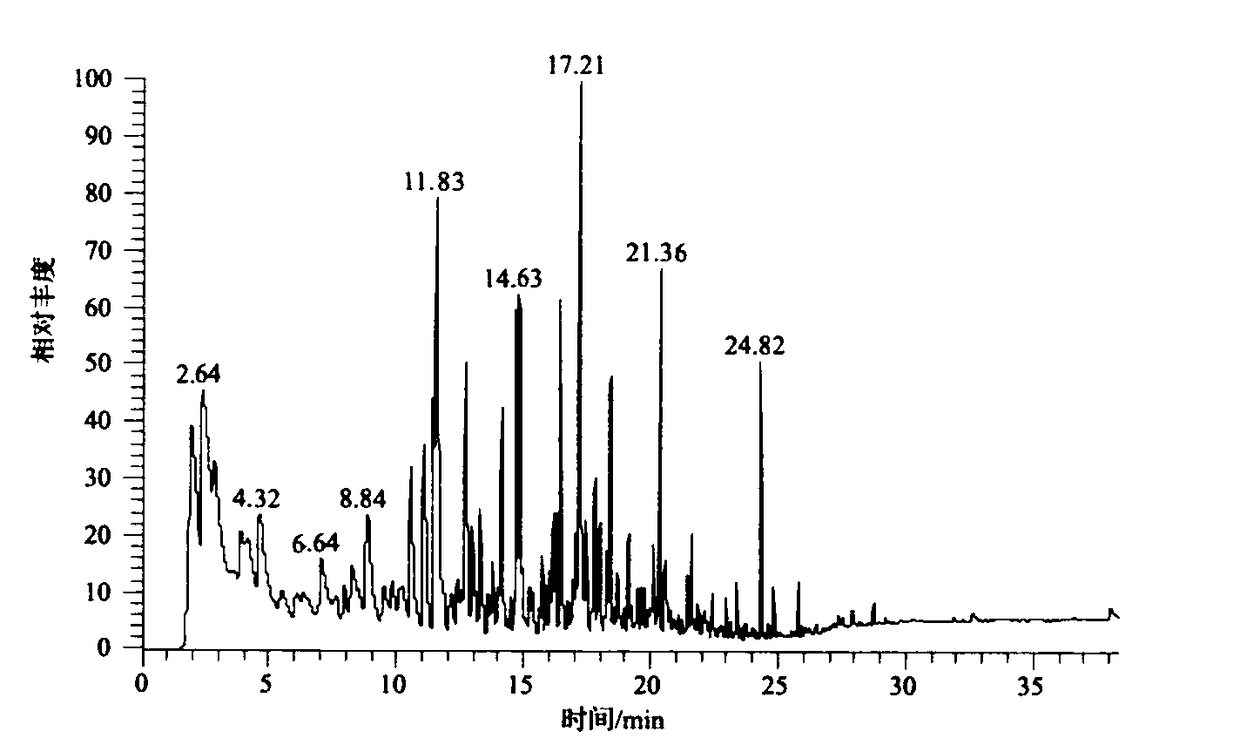

Embodiment 3

[0055] A preparation method of cuttlefish toner, comprising the following steps:

[0056] (1) get fresh cuttlefish, dissect and kill, get its ink sac, collect Chinese ink;

[0057] (2) The ink is treated with irradiation; the irradiation dose is (2-5)×10 4 Gy;

[0058] (3) Add L-cysteine, maltodextrin, fructose, carboxypeptidase B and malic acid in ink, and the ratio of ink and each component is 100:3:6:5:0.5:0.1 successively, and then React at 40-50°C for 30-40min;

[0059](4) Then add 3% citric acid, 2% glucose, 0.5% methionine, 0.3% sodium alginate, react at 100°C for 10-15min, after stirring, let stand at room temperature for 12-20h; and adjust the pH to 6 -6.5;

[0060] (5) Add β-cyclodextrin to the reaction product, the mass ratio of β-cyclodextrin is 0.2%, stir and react at 30-35°C for 10-30min; and adjust the pH to 6.5;

[0061] (6) Take off the suspension of the lower layer, and centrifuge to obtain the precipitate;

[0062] (7) drying the precipitate at 50-60° ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com