Method for preparing electrode carbon material for electrochemical capacitor from peanut shells

A technology for capacitors and carbon materials, applied in the field of biomass carbon material preparation, can solve the problems of difficult to achieve technology, difficult to separate components, insoluble biomass of biomass, etc., to reduce active sites, reduce specific surface area, specific surface area, etc. big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A preparation method of an electrode carbon material for an electrochemical capacitor, comprising the following steps:

[0031] (1) Pretreatment of peanut shells: wash and dry the collected peanut shells in an ultrasonic instrument, and pass through a 100-mesh sieve after crushing;

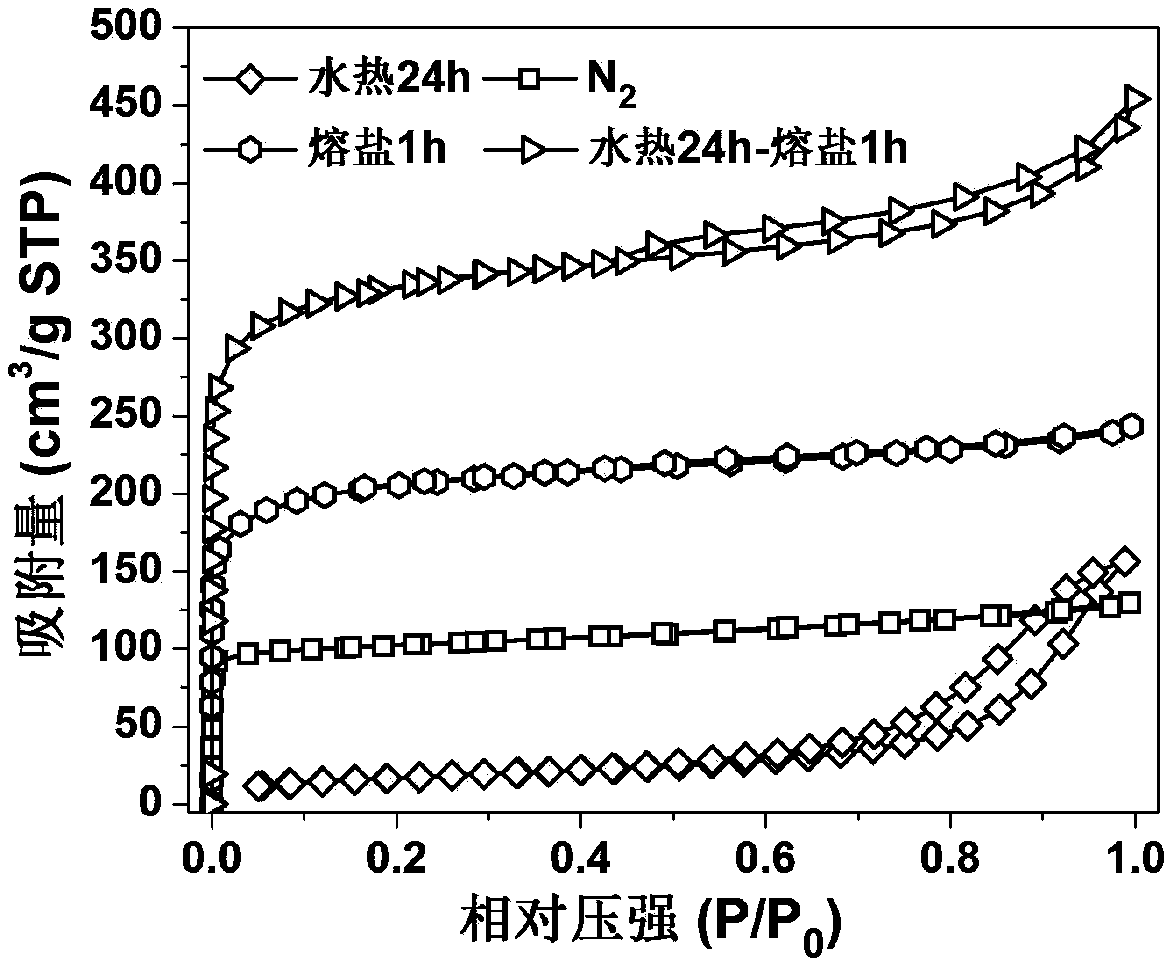

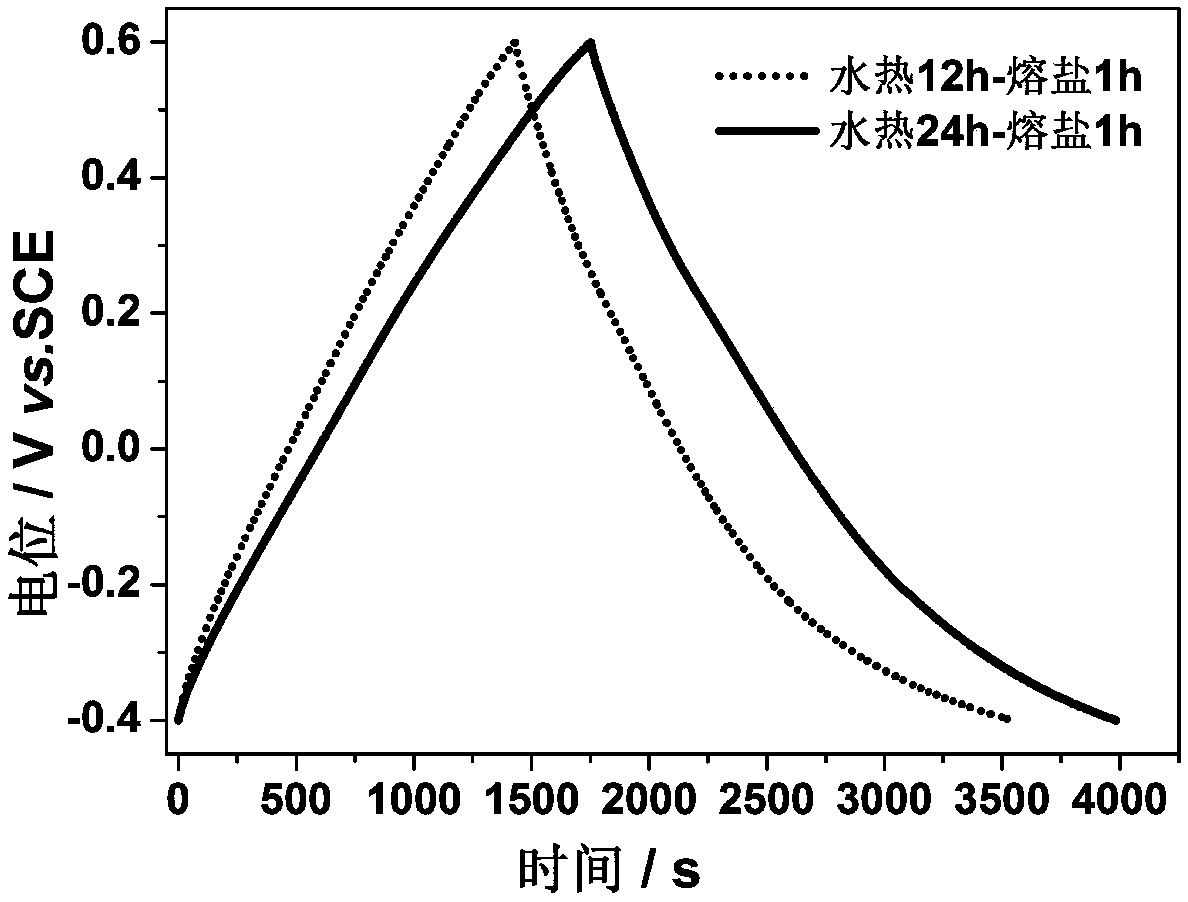

[0032] (2) Hydrothermal treatment: Weigh 6.0g of the peanut shell powder in step (1), add it to the hydrothermal reaction kettle, then add 60mL of deionized water, mix well; then put the reaction kettle at 200°C for hydrothermal reaction After 24 hours, filter and dry after the reaction to obtain lignite-like biomass hydrothermal carbon;

[0033] (3) Molten salt activation treatment: get 2.0g of hydrothermal carbon obtained in step (2), add 8.0g of Na 2 CO 3 -K 2 CO 3 Binary mixed salt, mixed evenly, placed in a corundum porcelain boat, placed in a tube furnace, in N 2 Under the protection of the atmosphere, pre-carbonize at 600°C for 1h, then heat up to 800°C for molten salt activatio...

Embodiment 2

[0036]A preparation method of an electrode carbon material for an electrochemical capacitor, comprising the following steps:

[0037] (1) Pretreatment of peanut shells: wash and dry the collected peanut shells in an ultrasonic instrument, and pass through a 100-mesh sieve after crushing;

[0038] (2) Hydrothermal treatment: Weigh 6.0g of peanut shell powder in step (1), add it to the hydrothermal reaction kettle, then add 30mL deionized water, mix well; then put the reaction kettle at 200°C for hydrothermal reaction After 24 hours, filter and dry after the reaction to obtain lignite-like biomass hydrothermal carbon;

[0039] (3) Molten salt activation treatment: get 2.0g of hydrothermal carbon obtained in step (2), add 8.0g of Na 2 CO 3 -K 2 CO 3 Binary mixed salt, mixed evenly, placed in a corundum porcelain boat, placed in a tube furnace, in N 2 Under the protection of the atmosphere, pre-carbonize at 600°C for 1h, then heat up to 800°C for molten salt activation for 1h...

Embodiment 3

[0042] A preparation method of an electrode carbon material for an electrochemical capacitor, comprising the following steps:

[0043] (1) Pretreatment of peanut shells: wash and dry the collected peanut shells in an ultrasonic instrument, and pass through a 100-mesh sieve after crushing;

[0044] (2) Hydrothermal treatment: Weigh 6.0g of the peanut shell powder in step (1), add it to the hydrothermal reaction kettle, then add 60mL deionized water, mix well; then put the reaction kettle at 180°C for hydrothermal reaction After 24 hours, filter and dry after the reaction to obtain lignite-like biomass hydrothermal carbon;

[0045] (3) Molten salt activation treatment: get 2.0g of hydrothermal carbon obtained in step (2), add 8.0g of Na 2 CO 3 -K 2 CO 3 Binary mixed salt, mixed evenly, placed in a corundum porcelain boat, placed in a tube furnace, in N 2 Under the protection of the atmosphere, pre-carbonize at 600°C for 1h, then heat up to 800°C for molten salt activation f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com