a foam cleanser

A technology of foam cleaner and conditioner, which is applied in the field of cleaning agents. It can solve the problems of unsatisfactory ability to remove heavy oil and long-lasting stains, difficult to distinguish cleaning agents, and complex production processes, etc., to achieve ideal cleaning effect, wettability and penetration. Good performance and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

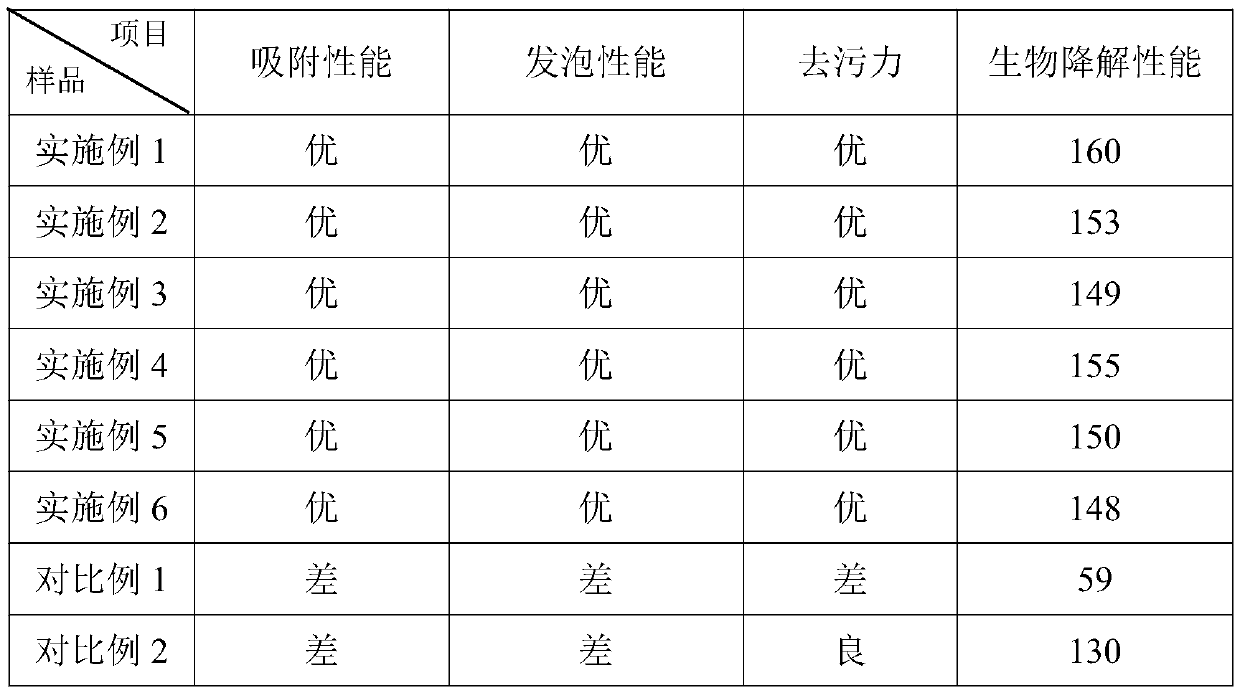

Embodiment 1

[0012] A foam cleaner, which is prepared from the following raw materials in mass percentage: 10% isomeric tridecanol polyoxyethylene ether, 3% ethylene glycol monobutyl ether or isopropanol, 1.5% ethanol, 2-octyl Alcohol polyoxyethylene ether 8%, cocamidopropyl betaine 5%, pH regulator 0.5%, glycerin 2%, and the balance is water. The pH regulator is NaOH.

[0013] The preparation method of described a kind of foam cleanser, concrete steps are:

[0014] Step 1) Weigh isomerized tridecyl alcohol polyoxyethylene ether, ethylene glycol monobutyl ether or isopropanol, ethanol, sec-octanyl polyoxyethylene ether, cocamidopropyl betaine, pH value according to the above formula amount conditioner, glycerin and water;

[0015] Step 2) will step 1) the isomerism tridecyl alcohol polyoxyethylene ether of formula quantity, the ethylene glycol monobutyl ether of formula quantity or Virahol, the ethanol of formula quantity, the secondary octanol polyoxyethylene ether of formula quantity a...

Embodiment 2

[0017] A foam cleaner, which is prepared from the following raw materials in mass percentage: 1% isomeric tridecanol polyoxyethylene ether, 1% ethylene glycol monobutyl ether or isopropanol, 1% ethanol, 2-octyl 1% alcohol polyoxyethylene ether, 1% cocamidopropyl betaine, 0.1% pH regulator, 1% glycerin, and the balance is water. The pH regulator is NaOH.

[0018] The preparation method is the same as in Example 1.

Embodiment 3

[0020] A foam cleaner, which is prepared from the following raw materials in mass percentage: 15% isomeric tridecanol polyoxyethylene ether, 4% ethylene glycol monobutyl ether or isopropanol, 2% ethanol, 2-octyl Alcohol polyoxyethylene ether 15%, cocamidopropyl betaine 10%, pH regulator 1%, glycerin 3%, and the balance is water. The pH regulator is NaOH.

[0021] The preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com