Denitration heat-accumulating type burner for industrial furnace

An industrial furnace, regenerative technology, applied in the direction of regenerative equipment, furnaces, burners, etc., can solve the problems of large air pollution and many nitrides, and achieve the effects of reducing emissions, improving efficiency, and improving heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

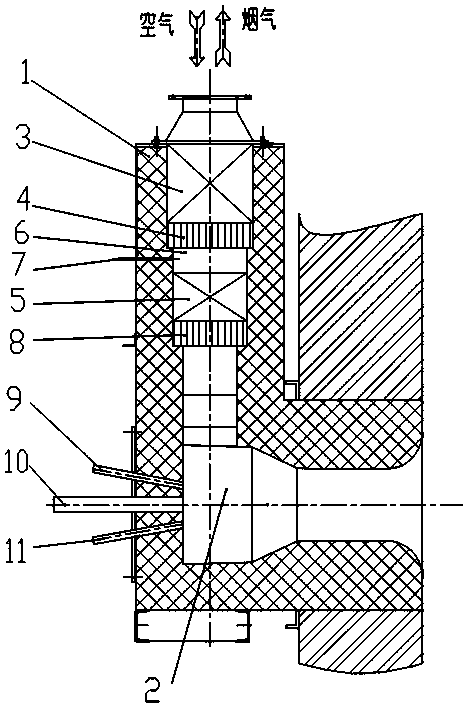

[0015] Such as figure 1 As shown, the denitrification regenerative burner for industrial furnaces of the present invention includes a burner body 1, on which a gas channel 2 is arranged, and the gas channel 2 is a through type, which enters the industrial furnace furnace as an external combustion-supporting gas respectively. The channel and the channel for the exhaust of high-temperature flue gas in the furnace of the industrial furnace; on the gas channel 2, along the intake direction of the combustion-supporting gas, there are honeycomb ceramic bodies 3 and regenerators 5 before and after, and the honeycomb ceramic body 3 has a number of small holes In order to allow the combustion-supporting gas or high-temperature flue gas to pass through, a catalyst (catalyst) for denitration reaction is provided in the hole of the honeycomb ceramic body 3, or on the inner surface of the hole. The specific material or component of the catalyst is determined by the SCR denitrification techn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com