Electrolyte and secondary battery

A secondary battery and electrolyte technology, applied in the field of electrolyte and secondary battery, can solve the problems of shortening the use time of end products, worsening battery life, battery capacity loss, etc., and improving the room temperature cycle performance and high temperature storage performance. , good compatibility, low impedance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Embodiment 1: the preparation of electrolyte L1#~L12#

[0018] According to the mass ratio EC:DEC:PC:FEC=30:50:15:5 uniformly mix EC, DEC, PC and FEC to form an organic solvent, take fully dried lithium salt LiPF 6 Dissolve in the above organic solvent to obtain a lithium salt concentration of 1 mol / L, then add the combined additives BMI and MMDS, and mix evenly to obtain an electrolyte. The structural formula of the BMI is: The structural formula of the MMDS is:

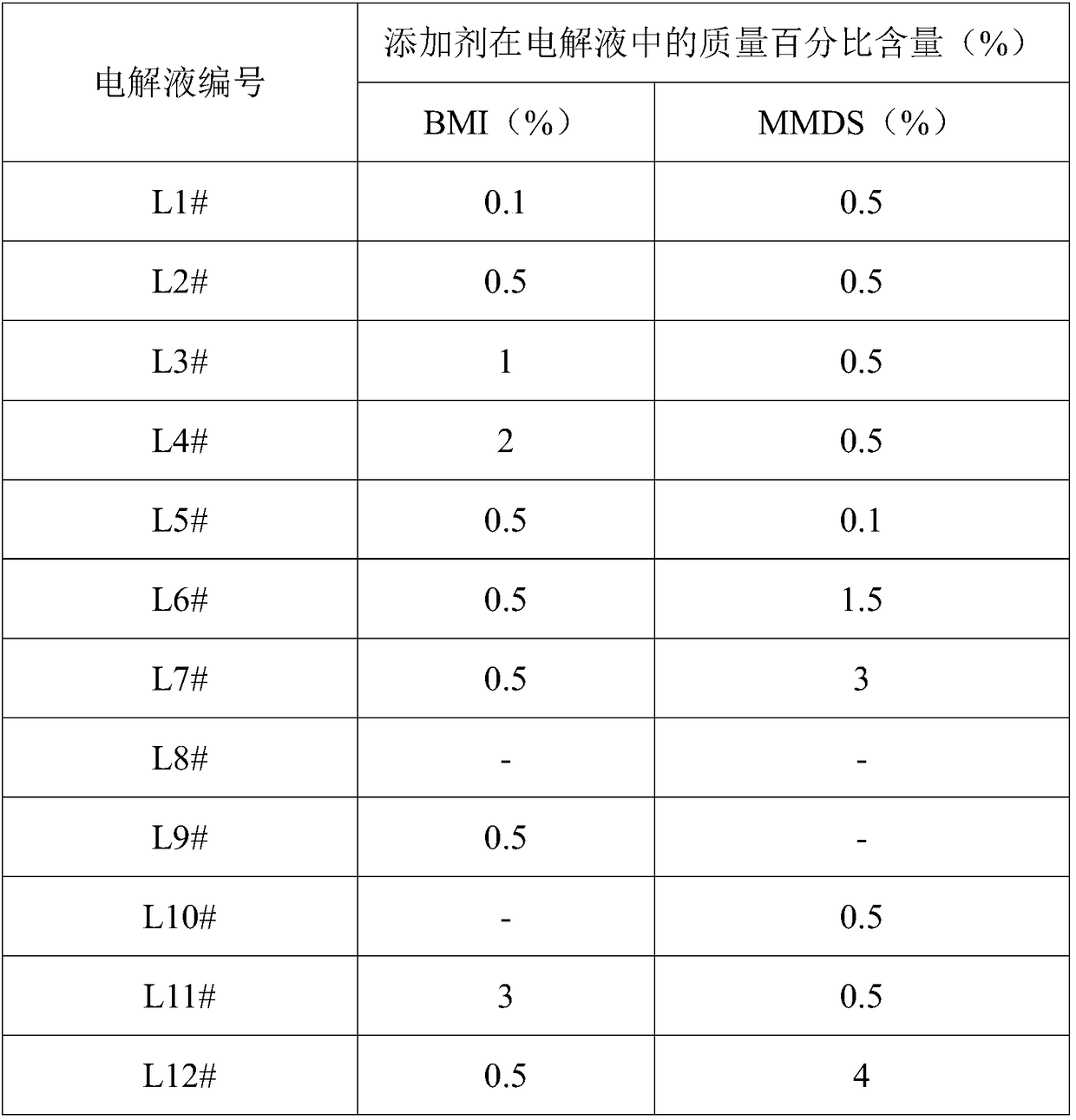

[0019] The composition relationship of the combined additives in the electrolyte L1#~L12# is shown in Table 1.

[0020] Table 1

[0021]

Embodiment 2

[0022] Embodiment 2: Preparation of lithium ion batteries B1#~B12#

[0023] (1) Preparation of positive electrode sheet: lithium cobalt oxide (LiCoO 2 ), binder (polyvinylidene fluoride), conductive agent (acetylene black) according to the weight ratio of LiCoO 2 : polyvinylidene fluoride: acetylene black = 96: 2: 2 to mix, add N-methylpyrrolidone (NMP), stir under the action of a vacuum mixer until the system becomes uniform, and obtain the positive electrode slurry; evenly coat the positive electrode slurry Covered on an aluminum foil with a thickness of 12 μm; the aluminum foil was dried at room temperature, then transferred to an oven at 120° C. for 1 hour, and then subjected to cold pressing and slitting to obtain positive electrode sheets.

[0024] (2) Preparation of negative plate: graphite, acetylene black, thickener sodium carboxymethyl cellulose (CMC), and binder styrene-butadiene rubber are graphite in weight ratio: acetylene black: binder styrene-butadiene rubber:...

Embodiment 3

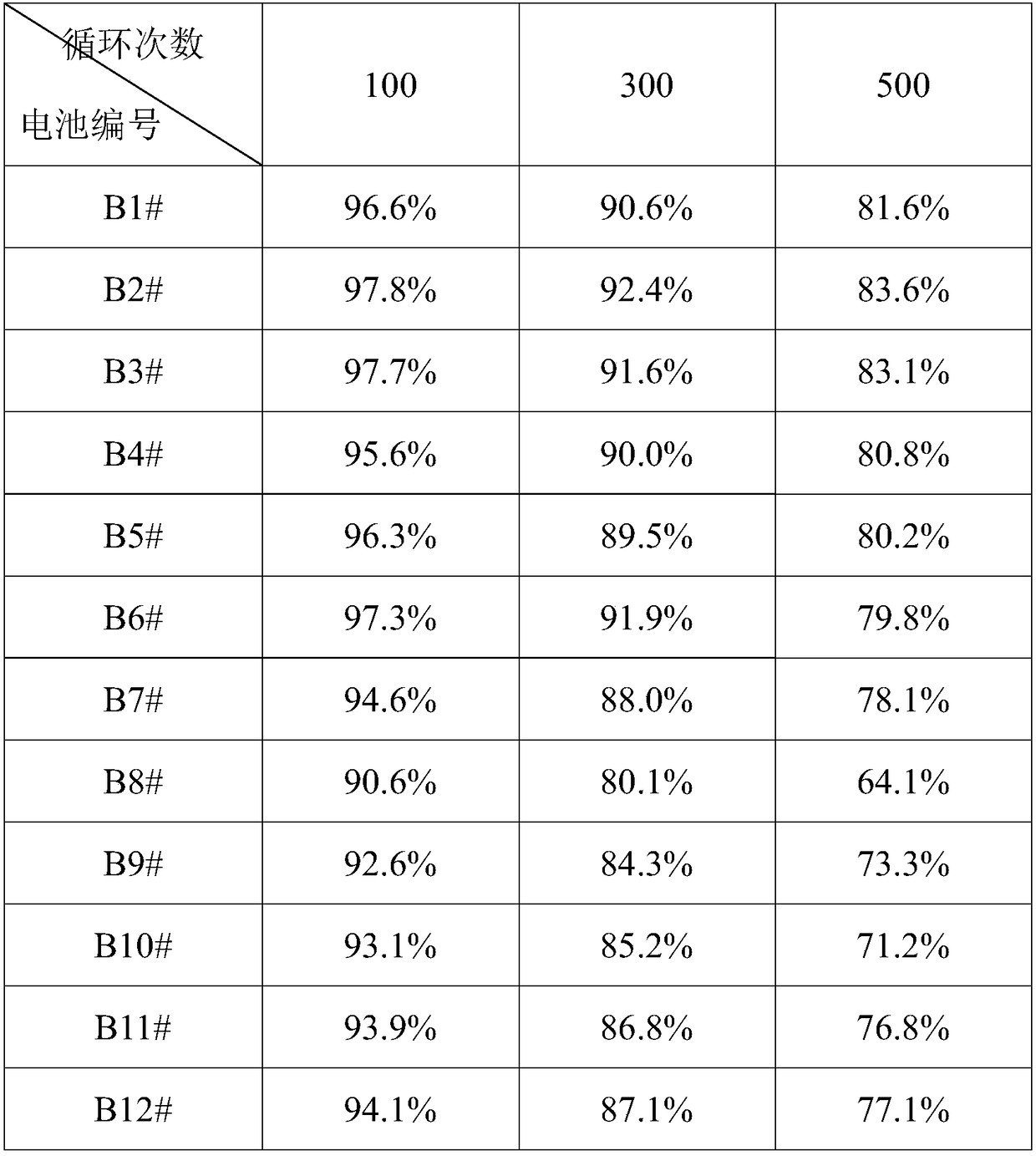

[0026] Embodiment 3: The cycle performance test of lithium ion battery B1#~B12#

[0027] The lithium-ion batteries B1# to B12# in Example 2 were tested according to the following method: at 25°C, the lithium-ion batteries were charged at a constant current of 1C to 4.4V, and then charged at a constant voltage to a current of 0.05C. Then use 1C constant current to discharge to 3.0V. At this time, it is the first cycle. According to the above cycle conditions, carry out 100, 300, and 500 cycles of charging / discharging, respectively, and calculate the battery cycles of 100, 300, and 500 cycles. The capacity retention rate after the cycle, wherein, the capacity retention rate after the cycle is calculated according to the following formula, the capacity retention rate after the cycle = (discharge capacity after the corresponding number of cycles / discharge capacity for the first cycle) × 100%, each lithium ion battery See Table 2 for relevant test data obtained through testing.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com