Method of manufacturing organic fertilizers by using organic raw material, antagonistic microorganism, fermentative microorganism, and synthetic microorganism, and organic fertilizers manufactured by said manufacturing method

A technology of microbiome and production method, applied in the field of organic fertilizer, can solve the problems of complicated planting, storage, and difficulty in use by ordinary farmers, and achieve the effects of increasing income, easy processing, and improving microbial conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

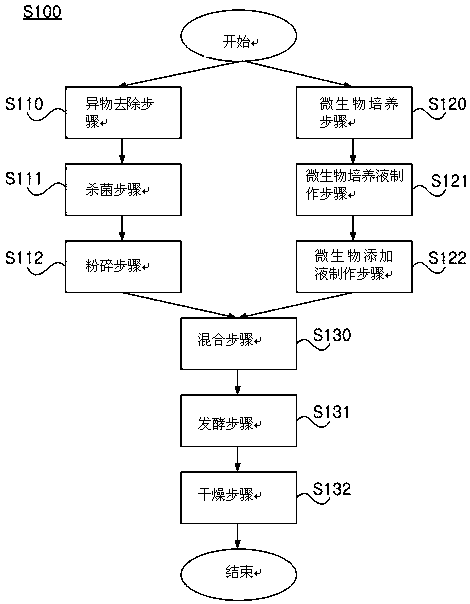

[0044] With regard to the detailed description of the present invention described below, specific examples for carrying out the present invention will be described with reference to the accompanying drawings. The following embodiments are described in detail so that those skilled in the art can fully understand. Although the various embodiments of the invention are different, they are not mutually exclusive. For example, the specific shapes, structures and characteristics described here are related to this embodiment, but can be applied to other embodiments without departing from the technical idea and scope of the present invention. In addition, the position and arrangement of each component in each embodiment can be changed without departing from the technical idea and scope of the present invention. Therefore, the following detailed description is not intended to be a limiting condition, and the scope of the present invention is only limited by the contents of the claims a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com