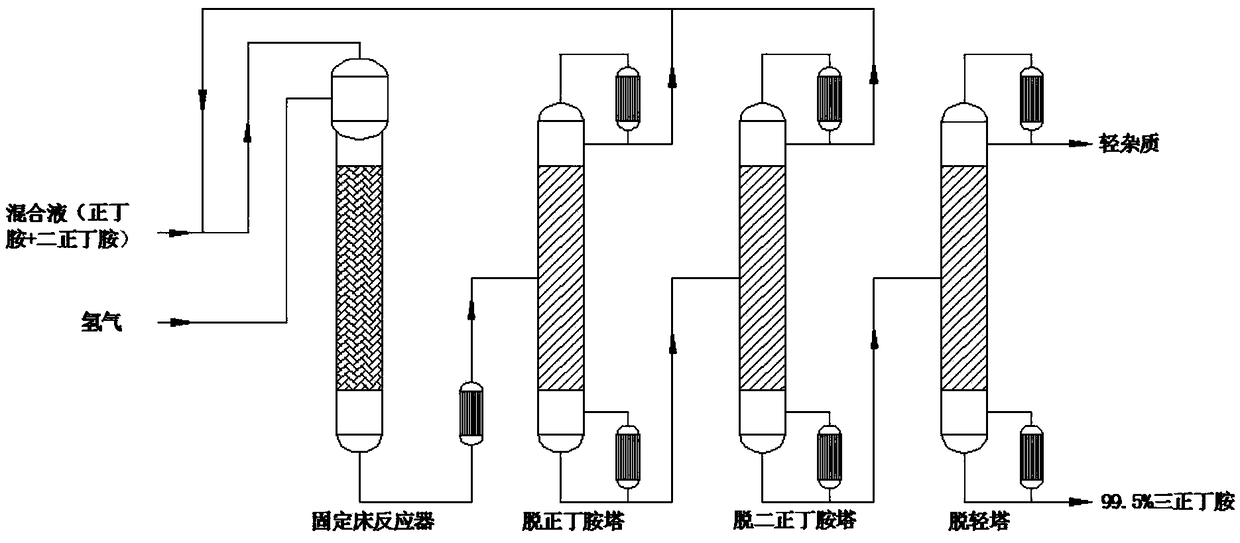

Tri-n-butylamine production device with dividing-wall distillation columns

A technology of dividing wall rectification column and tri-n-butylamine, which is applied in the field of tri-n-butylamine production equipment, can solve the problem of high energy consumption, achieve the effects of reducing energy consumption, saving equipment investment and energy consumption, and ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

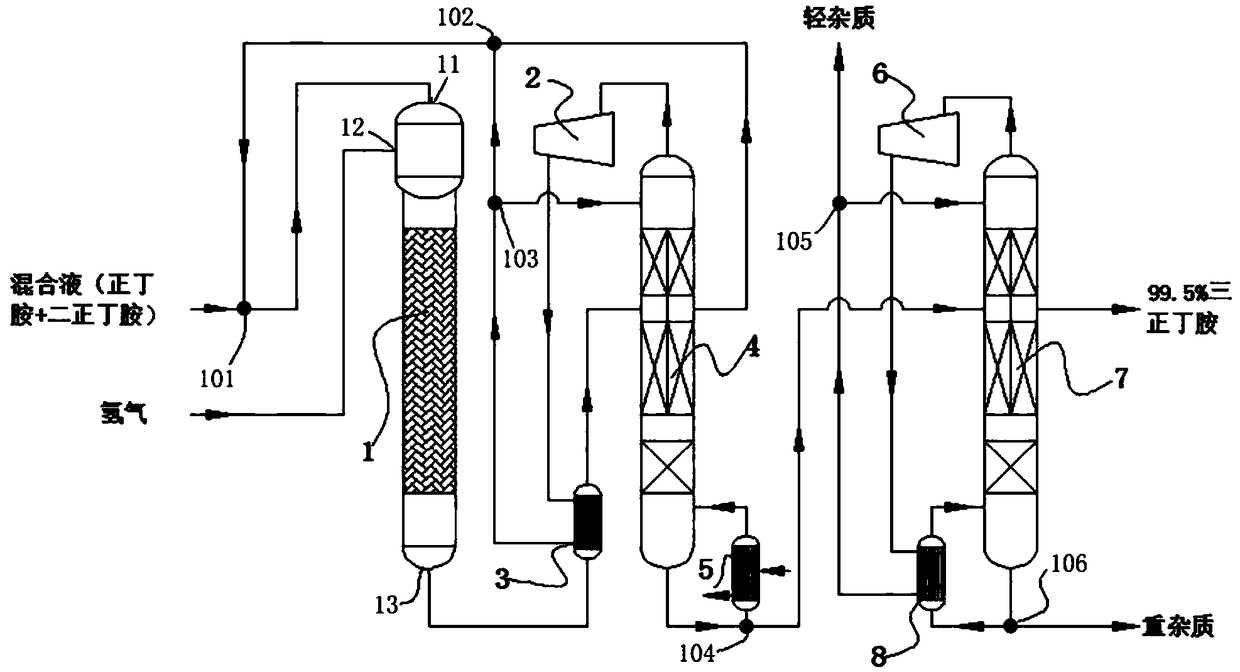

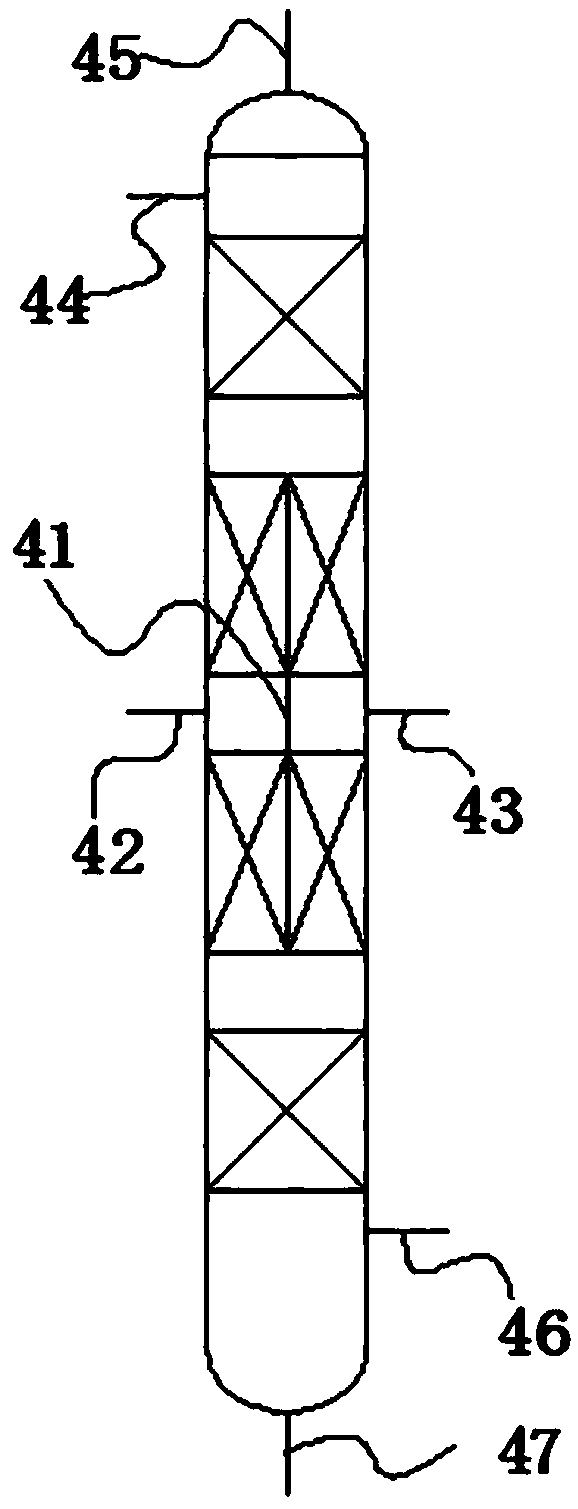

[0031] Embodiment 1, a kind of tri-n-butylamine production device that uses dividing wall rectification tower, such as figure 2 and image 3 As shown, it includes a fixed bed reactor 1, a first heat pump 2, a first heat exchanger 3, a first dividing wall rectification column 4, a second heat exchanger 5, a second heat pump 6, and a second dividing wall rectification column 7 and the third heat exchanger 8.

[0032] The upper part of the fixed bed reactor 1 is a vaporization mixing chamber, and the lower part is a fixed bed, and the vaporization mixing chamber is provided with a mixed solution inlet 11 and a hydrogen inlet 12, and the mixed solution inlet 11 is located above the hydrogen inlet 12; the fixed The bed is filled with a catalyst, and the bottom of the fixed bed is provided with a reactant outlet 13;

[0033] The first heat pump 2 and the second heat pump 6 are respectively provided with respective inlets and outlets; both the first heat pump 2 and the second heat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com