Antibacterial reduced graphene oxide modified polypropylene melt-blown water purification filter element

A polypropylene meltblown, water purification filter technology, used in alkali metal oxides/hydroxides, sterilization/microdynamic water/sewage treatment, bactericides, etc. Use and other problems to achieve the effect of lasting antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

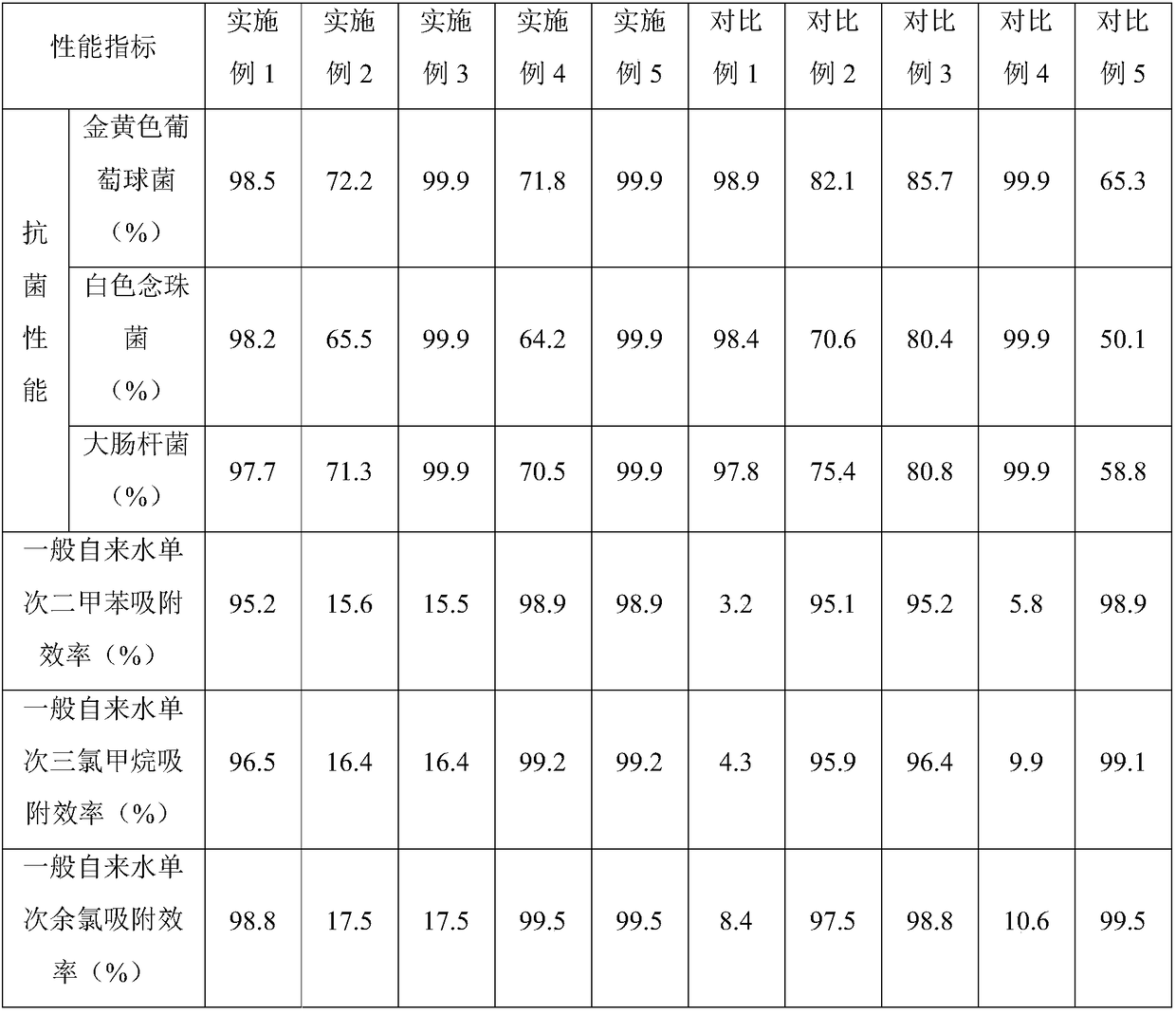

Examples

Embodiment 1

[0033] This embodiment provides a method for preparing an antibacterial reduced graphene oxide modified polypropylene meltblown water purification filter element, and the specific steps are as follows:

[0034] 1. Disperse graphene oxide GO (prepared by the improved Hummers method) in deionized water under ultrasonic action at room temperature, wherein the mass ratio of the graphene oxide to deionized water is about 1:500;

[0035] 2. Dissolve an appropriate amount of n-dodecyl methyl silane in ethanol at room temperature, and mix with magnetic stirring, wherein the mass ratio of n-dodecyl methyl silane to ethanol is about 1:50;

[0036] 3. Mix the solutions prepared in steps 1 and 2 according to a mass ratio of 2:1, then heat up to 70°C, and react with magnetic stirring for 1 hour to obtain silane graft-modified graphene oxide;

[0037] 4. Add a small amount of hydrazine hydrate and ammonia water to the solution prepared in step 3, where the mass ratio of hydrazine hydrate and ammonia...

Embodiment 2

[0045] This embodiment provides a method for preparing an antibacterial reduced graphene oxide modified polypropylene meltblown water purification filter element, and the specific steps are as follows:

[0046] 1. Disperse graphene oxide GO (prepared by the improved Hummers method) in deionized water under ultrasonic action at room temperature, wherein the mass ratio of the graphene oxide to deionized water is about 1:500;

[0047] 2. Dissolve an appropriate amount of n-dodecyl methyl silane in ethanol at room temperature, and mix with magnetic stirring, wherein the mass ratio of n-dodecyl methyl silane to ethanol is about 1:50;

[0048] 3. Mix the solutions prepared in steps 1 and 2 according to a mass ratio of 2:1, then heat up to 70°C, and react with magnetic stirring for 1 hour to obtain silane graft-modified graphene oxide;

[0049] 4. Add a small amount of hydrazine hydrate and ammonia water to the solution prepared in step 3, where the mass ratio of hydrazine hydrate and ammonia...

Embodiment 3

[0057] This embodiment provides a method for preparing an antibacterial reduced graphene oxide modified polypropylene meltblown water purification filter element, and the specific steps are as follows:

[0058] 1. Disperse graphene oxide GO (prepared by the improved Hummers method) in deionized water under ultrasonic action at room temperature, wherein the mass ratio of the graphene oxide to deionized water is about 1:500;

[0059] 2. Dissolve an appropriate amount of n-dodecyl methyl silane in ethanol at room temperature, and mix with magnetic stirring, wherein the mass ratio of n-dodecyl methyl silane to ethanol is about 1:50;

[0060] 3. Mix the solutions prepared in steps 1 and 2 according to a mass ratio of 2:1, then heat up to 70°C, and react with magnetic stirring for 1 hour to obtain silane graft-modified graphene oxide;

[0061] 4. Add a small amount of hydrazine hydrate and ammonia water to the solution prepared in step 3, where the mass ratio of hydrazine hydrate and ammonia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com