Aramid fiber conveyor belt

A conveyor belt and aramid fiber technology, applied in the direction of conveyor, transportation and packaging, can solve the problems of difficult adhesion between aramid canvas and rubber layer, delamination of conveyor belt layers, and many conveyor belt layers. The effect of light weight, long service life and low operating energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

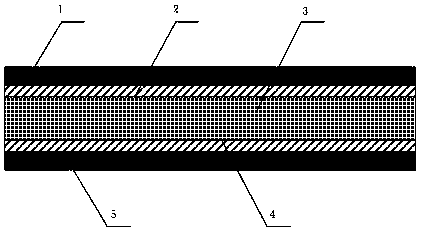

[0024] Such as figure 1 The shown aramid conveyor belt comprises an upper covering layer 1, an upper bonding layer 2, an intermediate layer 3, a lower bonding layer 4, and a lower covering layer 5, and the intermediate layer 3 is an aramid fiber belt embryo, and the aramid fiber The belt blank is plasticized after impregnating the aramid fiber core with the paste. The aramid tape core is a two-layer mesh structure woven with aramid fiber as the warp and polyester yarn and cotton yarn as the weft. The twist of plying is 60 turns / meter. The thickness of the upper adhesive layer 2 is 3 mm, and the thickness of the lower adhesive layer 4 is 3 mm. The upper cover layer 1 has a thickness of 1 mm, and the lower cover layer 5 has a thickness of 1 mm.

Embodiment 2

[0026] Such as figure 1 The shown aramid conveyor belt comprises an upper covering layer 1, an upper bonding layer 2, an intermediate layer 3, a lower bonding layer 4, and a lower covering layer 5, and the intermediate layer 3 is an aramid fiber belt embryo, and the aramid fiber The belt blank is plasticized after impregnating the aramid fiber core with the paste. The aramid tape core is a 4-layer mesh structure woven from aramid fibers as warp threads and ply threads of nylon and cotton yarns as weft threads. The twist of plying is 80 turns / meter. The thickness of the upper adhesive layer 2 is 1 mm, and the thickness of the lower adhesive layer 4 is 1 mm. The upper cover layer 1 has a thickness of 2 mm, and the lower cover layer 5 has a thickness of 2 mm.

Embodiment 3

[0028] Such as figure 1 The shown aramid conveyor belt comprises an upper cover layer 1, an upper adhesive layer 2, an intermediate layer 3, a lower adhesive layer 4, and a lower cover layer 5, and the middle 3 layers are aramid fiber belt embryos, and the aramid fiber The belt blank is plasticized after impregnating the aramid fiber core with the paste. The aramid tape core is a 6-layer mesh structure woven from aramid fibers as warp threads and ply threads of nylon and cotton yarns as weft threads. The twist of plying is 70 turns / meter. The thickness of the upper adhesive layer 2 is 2 mm, the thickness of the lower adhesive layer 4 is 2.5 mm, the thickness of the upper covering layer 1 is 2 mm, and the thickness of the lower covering layer 5 is 1.5 mm.

[0029] The aramid conveyor belt of the present invention can be used in large-scale coal mines, ports, iron and steel, metallurgy, cement and other industries, especially for long-distance transportation of high-load mater...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com