Cement grinding aid and application thereof

A cement grinding aid and modification technology, which is applied in the field of chemical building materials, can solve problems such as difficulty in meeting homogeneity index requirements, unfavorable cement stone structure growth, and large differences in strength growth, so as to reduce environmental burdens, ensure strength, Take full advantage of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A cement grinding aid, the cement grinding aid is made of the following raw materials in mass percentage: 16% of modified propanolamine, 5% of polymerized glycerin, 7% of sweet raisin molasses, the rest is water, and the grinding aid of foreign brands Agent Grace, Sika comparative test.

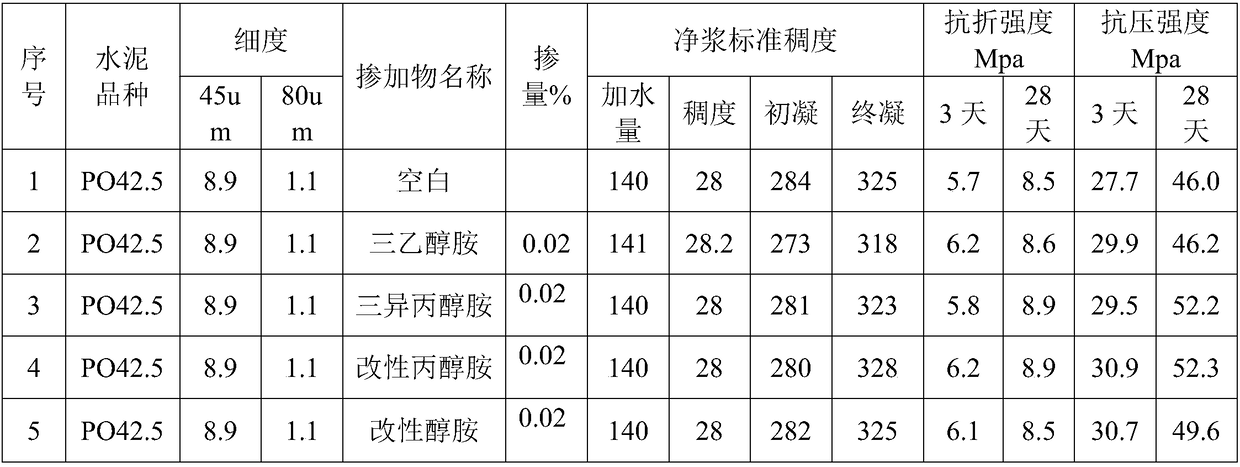

[0025] The implementation cases are as follows:

[0026] 1) Take the clinker, mixed materials and gypsum used in the production of a certain factory, and put them into the uniform test small mill in the laboratory. After 27 minutes of grinding time, the sampling test shows that the 45μm and 80μm sieves are 14.2% and 2.7%, respectively, and the specific surface area is 3953cm 2 / g; then carry out the mortar strength test according to GB / T17671-1999 "Cement Mortar Strength Test Method (ISO Method)", add the recommended dosage of grinding aid into the test mixing water, and check the cement 3d and 28d age. The compressive strength, the test results are as follows:

[0027]

[0028] ...

Embodiment 2

[0033] A cement grinding aid, which is made of the following raw materials in mass percentage: 10% of modified propanolamine, 1% of polyglycerin, 5% of sweet molasses, and the rest is water.

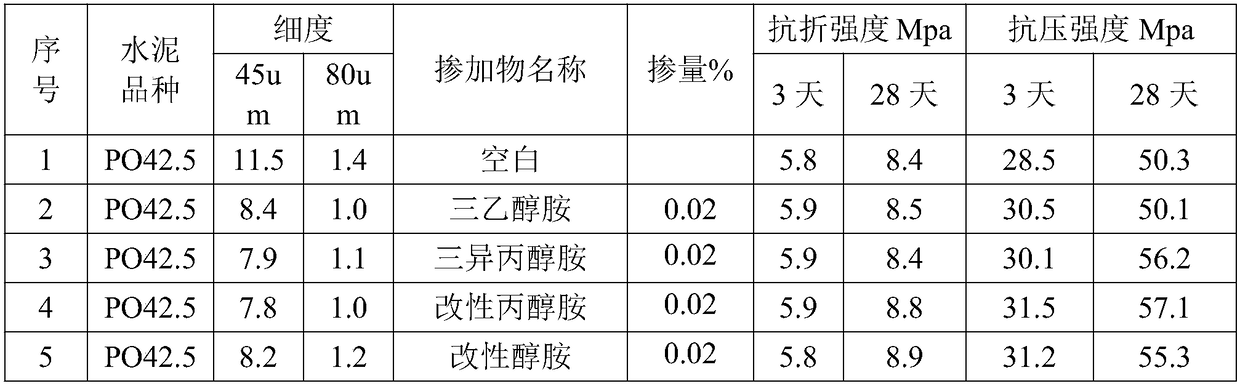

[0034] The implementation cases are as follows:

[0035] Take clinker, mixed materials and gypsum for production in a certain factory, according to the method in Appendix A of GB / T 26748-2011 "Cement Grinding Aids", add new grinding aid tablet B, grind for the same time (27min), check the cement fineness Then, according to GB / T17671-1999 "Cement mortar strength test method (ISO method)", the mortar strength test is carried out to test the compressive strength of cement at 3d and 28d ages, and the test results are as follows:

[0036]

[0037] Test results and discussion: Compared with the blank cement mixed with the new grinding aid B, the sieve allowances of 45 μm and 80 μm decreased by 4.6% and 1.1% respectively, and the compressive strength of cement increased by 3d and 28d respect...

Embodiment 3

[0039]A cement grinding aid is made of the following raw materials in mass percentage: 30% of modified propanolamine, 6% of polymerized glycerin, 15% of sweet molasses, and the rest is water.

[0040] The implementation cases are as follows:

[0041] Take the clinker, mixed materials and gypsum used in the production of a certain factory, according to the method in Appendix A of GB / T 26748-2011 "Cement Grinding Aids", add new grinding aid C, grind for the same time (27min), and check the cement fineness Change; then according to GB / T17671-1999 "Cement mortar strength test method (ISO method)", the mortar strength test is carried out to test the compressive strength of cement at 3d and 28d ages, and the test results are as follows:

[0042]

[0043] Test results and discussion: Compared with the blank cement mixed with the new grinding aid C, the sieve allowances of 45 μm and 80 μm were reduced by 5.8% and 1.3% respectively, and the compressive strength of the cement was inc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com